Squeezing and extruding treatment method for soaked materials

A processing method and material technology, applied in the direction of combustion method, press, fuel supply, etc., can solve problems such as uneven feeding, and achieve the effects of saving processing costs, convenient use, and scientific principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

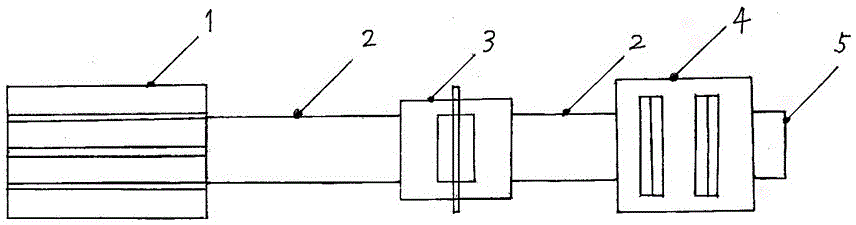

[0018] Referring to the accompanying drawings, the pressing and extruding processing method of soaked material of the present invention comprises the following steps: 1. Design a V-shaped discharge part 1 at the feed inlet of the boiler combustion processing system, and the After the wet material is decompressed, it is evenly input to the belt 2 head of the belt conveyor. 2. Design multiple dispersing and homogenizing devices 3 on the belt of the belt conveyor to distribute the wet material on the belt evenly. 3. On the belt conveyor A squeeze extruder 4 is designed at the rear of the belt conveyor to squeeze the uniform wet material on the belt so that the moisture content of the extruded material is low and uniform. 5. There is a set at the tail of the belt conveyor Discharge 5.

[0019] When working, the soaked material garbage brought by the car is discharged into the V-shaped unloading part 1, and after being decompressed by the unloading part, it is evenly transported to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com