A beam pumping unit with heat dissipation brake structure

A beam pumping unit and beam pumping technology, which is applied to mechanical equipment, brake actuators, brake components, etc., can solve the problem of inconvenient use, the inability to ensure that the beam pumping unit stops working quickly, and occupies a small area major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

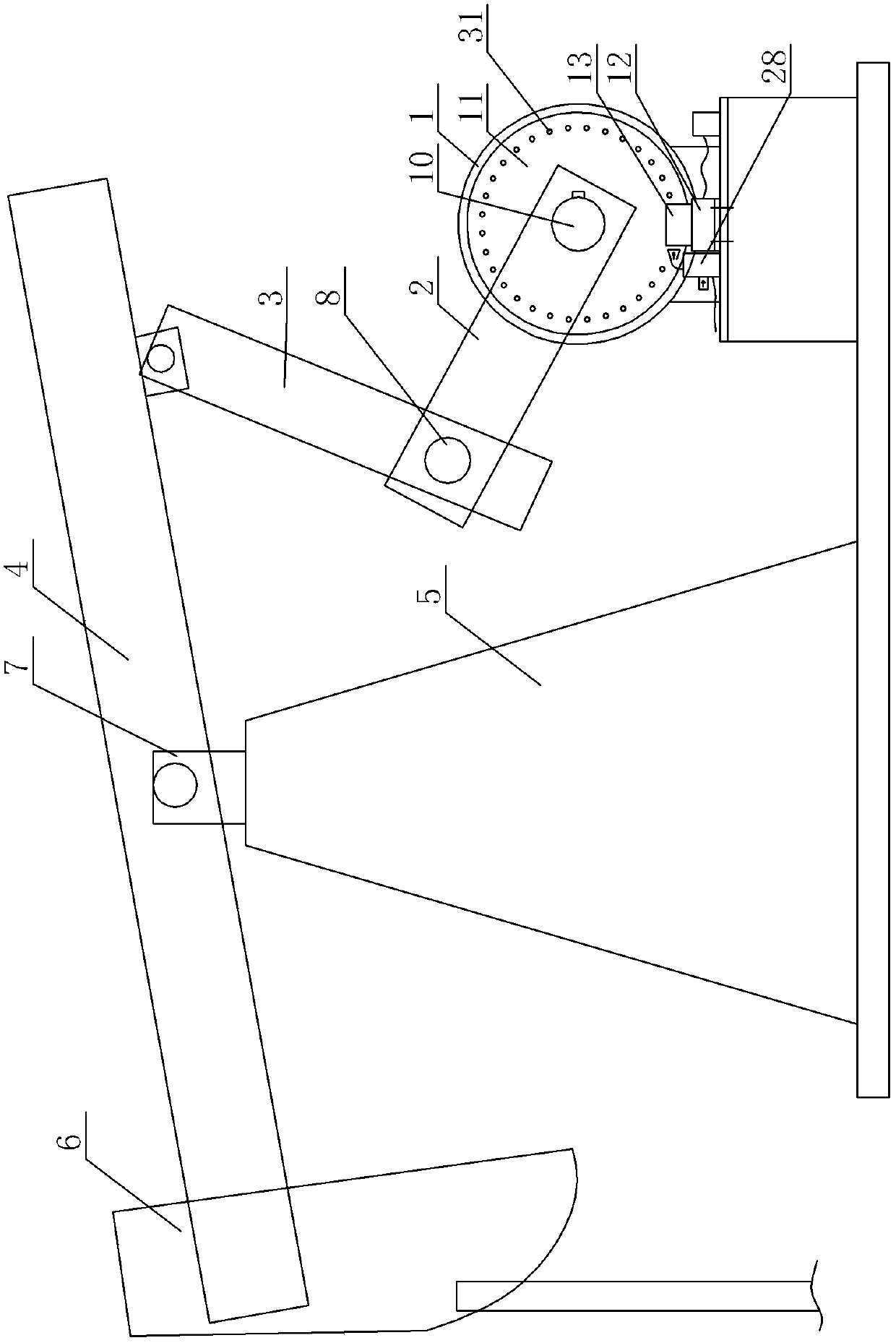

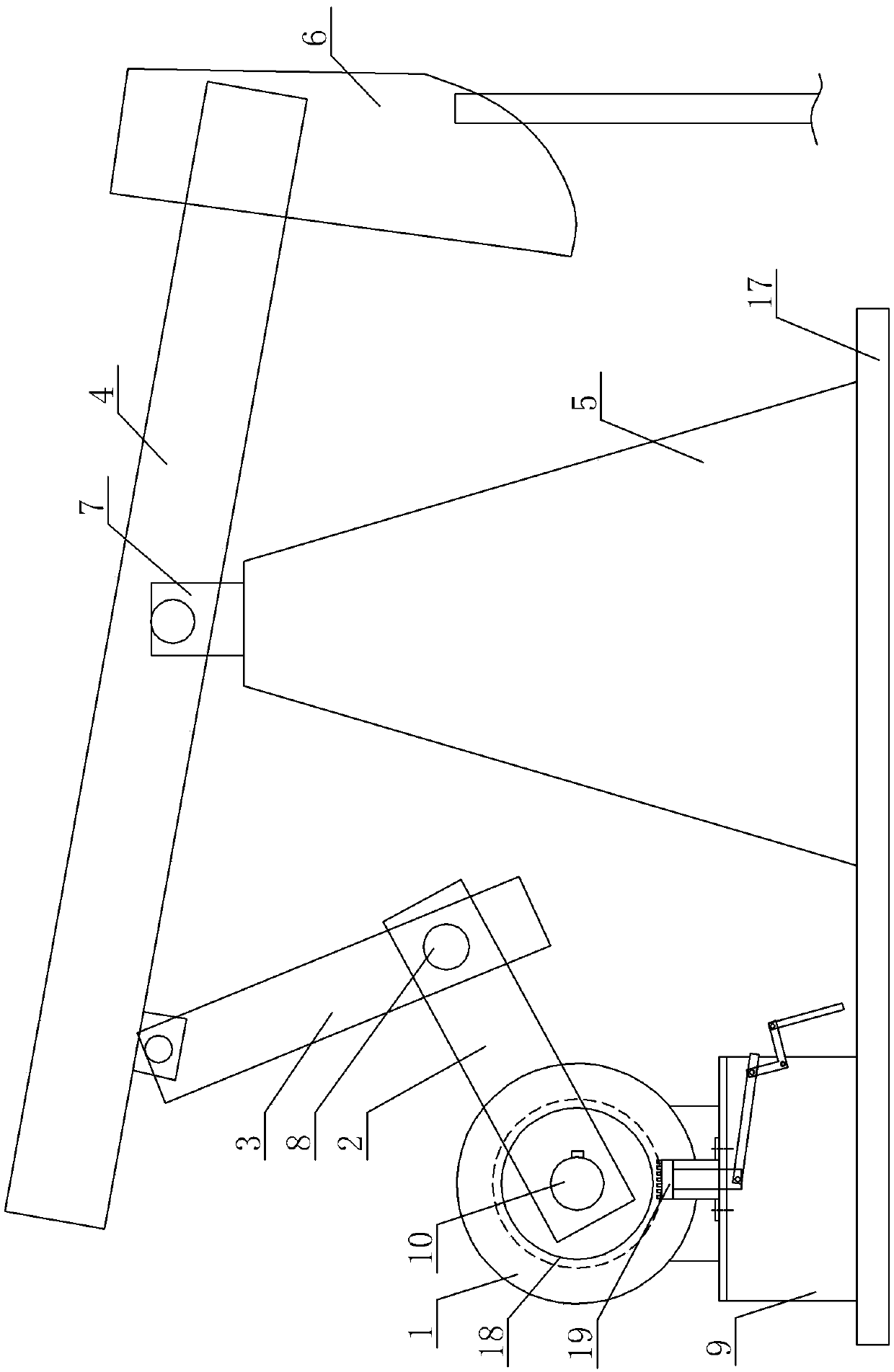

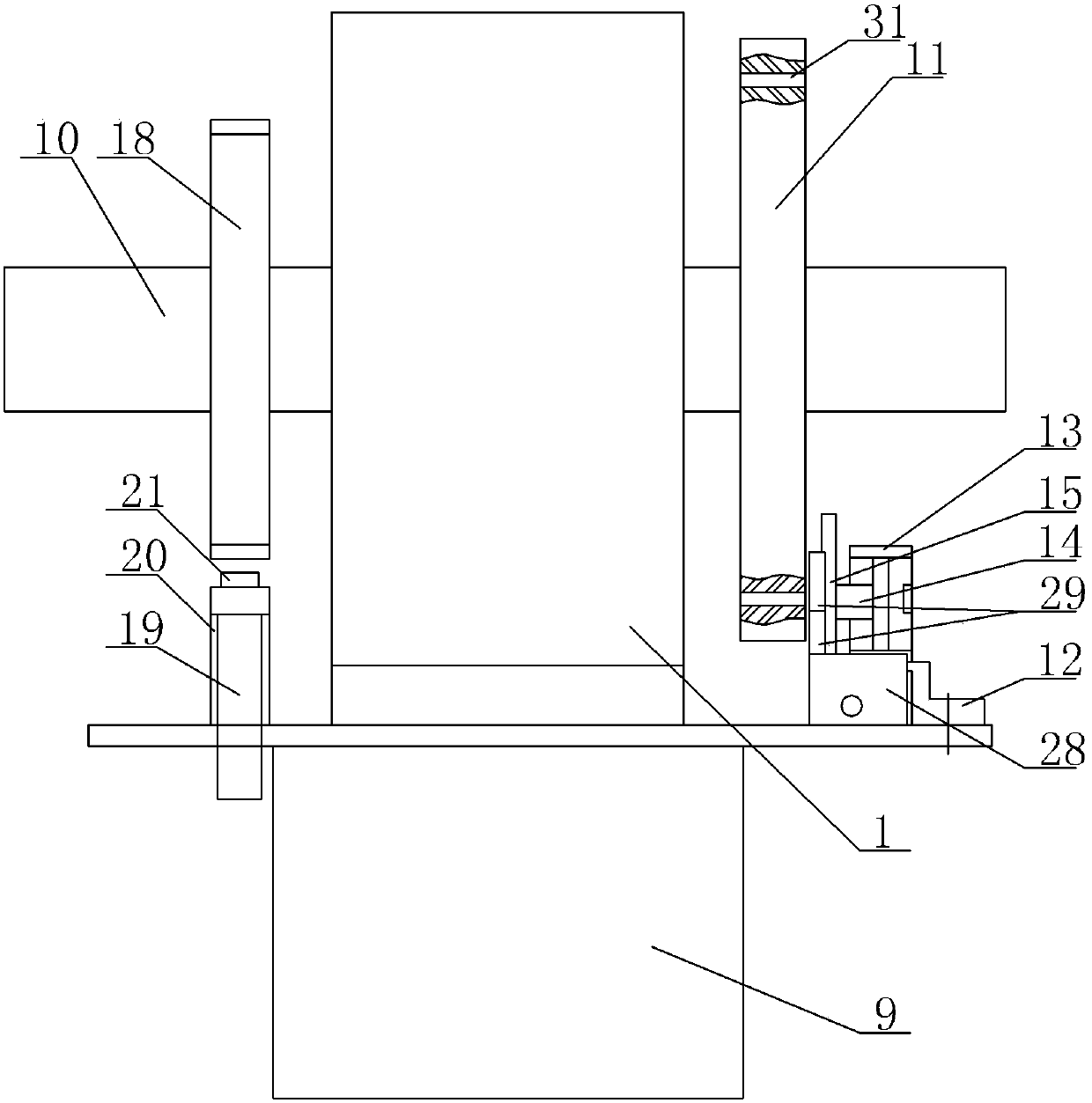

[0031] Specific embodiment one, see Figure 1 to Figure 5 : The linear feed part 13 is an oil cylinder structure, the output part 14 is a piston rod, the position of the brake pad support 12 towards the brake disc 11 is fastened with an oil cylinder structure, the piston rod of the oil cylinder structure is arranged towards the outer end surface of the brake disc 11, and the piston A brake pad 15 is fastened on the rod, and the braking area of the brake pad 15 is arranged toward the outer end surface of the brake disc 11, and an oil pump structure 27 is externally connected to the cavity of the oil cylinder structure through an oil pipe 26;

specific Embodiment 2

[0032]Specific embodiment two: the linear feed part 13 is an electric cylinder structure, and the position of the brake pad support 12 towards the brake disc 11 is fastened with an electric cylinder structure, and the piston rod of the electric cylinder structure is arranged towards the outer end surface of the brake disc 11. The piston rod of the cylinder structure is fastened with a brake pad 15, the braking surface of the brake pad 15 is arranged towards the outer end surface of the brake disc 11, and the electric cylinder is connected to an external power supply through a wire;

specific Embodiment 3

[0033] Specific embodiment three: the linear feed component 13 is a cylinder structure, the position of the brake pad support 12 towards the brake disc 11 is fastened with a cylinder structure, the piston rod of the cylinder structure is arranged towards the outer end surface of the brake disc 11, and the piston of the cylinder structure A brake pad 15 is fastened on the rod, and the braking area of the brake pad 15 is arranged toward the outer end surface of the brake disc 11, and a compressed air source is externally connected to the cavity of the cylinder structure through a gas pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com