Power battery management system of electric car

A battery management system and management system technology, applied in the field of electric vehicle power battery management system, can solve problems such as difficulty in guaranteeing functional safety, difficult effective management of charge and discharge, and inability to use, etc., to achieve the effect of guaranteed functional safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

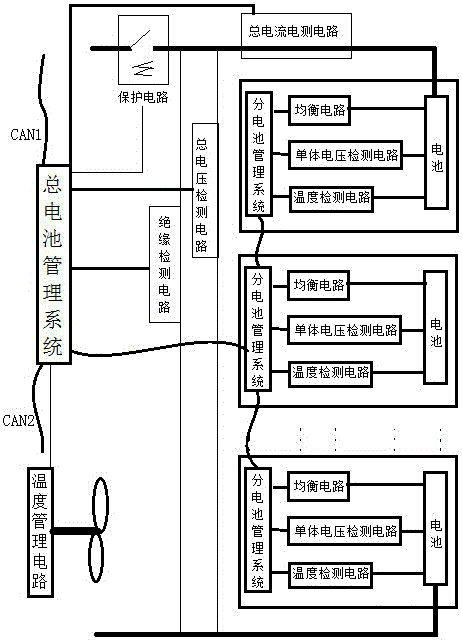

[0019] Such as figure 1 As shown, a power battery management system includes a power battery pack, a total battery management system CBMS, an insulation detection circuit, a total current detection circuit, a total voltage detection circuit, a protection circuit, a temperature management circuit, several sub-battery management systems SBMS, a single Body voltage detection circuit, temperature detection circuit, equalization circuit and CAN communication circuit. in:

[0020] The total battery management system CBMS is connected with the insulation detection circuit, the total current detection circuit, the total voltage detection circuit, the protection circuit, and the temperature management circuit, and the sub-battery management system is connected with the single voltage detection circuit, temperature detection circuit, and equalization circuit. The total battery management system and sub-battery management systems exchange data through CAN communication.

[0021] The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com