Device and method for removing inclusions through refined bubbles

A technology of inclusions and refining gas, which is applied in the fields of electromagnetic metallurgy and steelmaking, can solve the problems of easy corrosion and damage of the agitator, and achieve the effects of reducing the total amount of gas blowing, prolonging the residence time, and reducing the temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

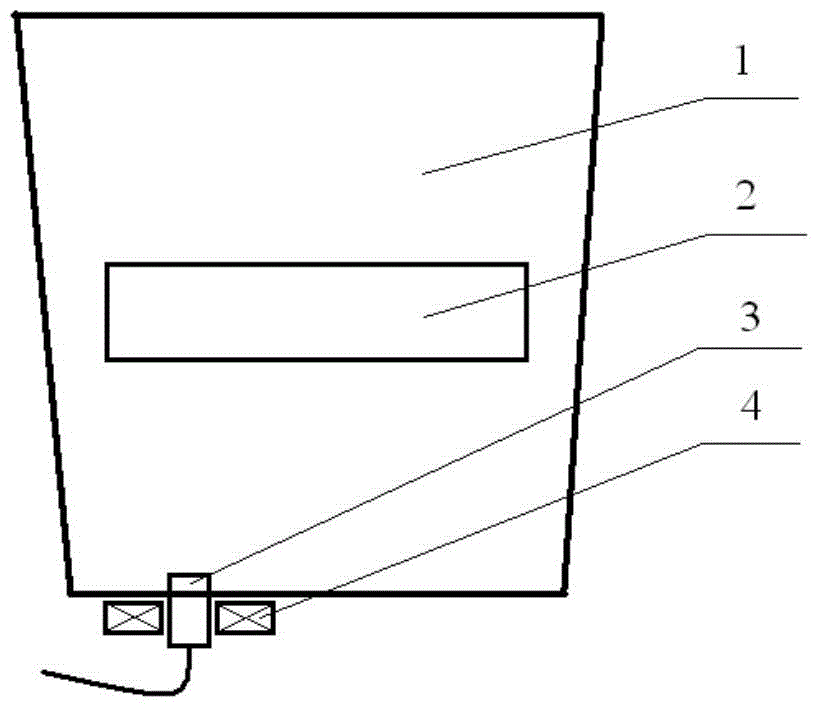

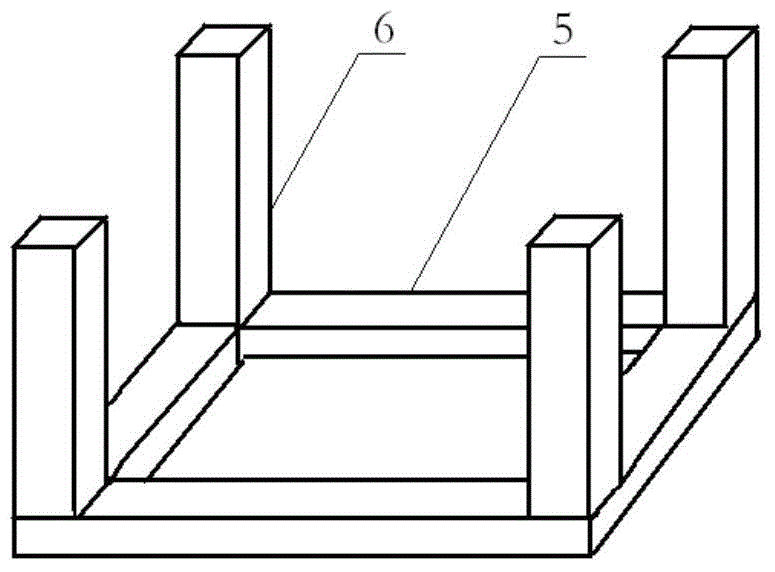

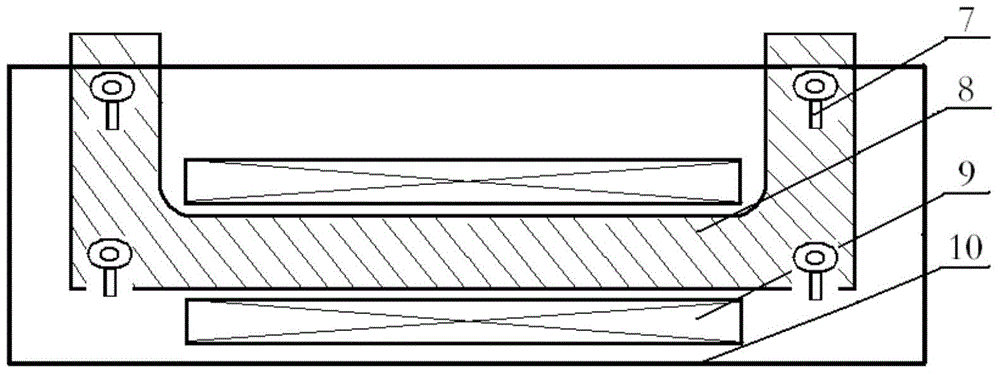

[0028] For a small-sized crucible containing molten metal, such as a crucible containing 500 kg of molten steel, the electromagnetic stirrer 4 can be placed near the bottom of the crucible near the breathable brick 3 to promote the flow of molten steel. The magnetic induction intensity of electromagnetic stirring is about 0.005-0.04T , The flow velocity of molten steel is about 0.2 ~ 1.5m / min. The electromagnetic braking magnetic field generator 2 is placed in the middle of the crucible. The casing of the electromagnetic braking magnetic field generator 2 is 950mm long, 550mm wide, and 700mm high. The box body 8 is made of white steel with a thickness of 2 mm. Because the brake iron core 8 and the brake coil 9 are heavier, about 200kg, there is a need to use channel steel as the skeleton inside the casing 10 to play a supporting role, and the suspension ring 7 is installed to facilitate transportation and installation. Depending on this device, the strongest magnetic field o...

Embodiment 2

[0030] Use 100 tons of ladle 1, use bottom blowing argon gas to purify molten steel, electromagnetic stirrer 4 is near the ventilating brick 3 at the bottom of ladle 1, stir molten steel, when the magnetic induction intensity near ventilating brick 3 reaches 0.005T, the flow speed of molten steel can reach 0.5m / min or more. The size of the electromagnetic braking magnetic field generator 2 is about 2m×1.5m×2m, and two sets of electromagnetic braking magnetic field generators 2 can be placed in pairs on both sides of the ladle 1, which can increase the penetration depth of the electromagnetic field and is beneficial to the ladle. 1 Electromagnetic braking of the middle molten steel. The magnetic field strength generated in molten steel reaches about 0.005-0.02T. Using the device within the same blowing time can increase the removal efficiency of small-sized inclusions (<5 μm) in molten steel by more than 30%, and can shorten the refining time, reduce the temperature drop of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com