Automatic spraying equipment for overhead power transmission line

An overhead transmission line and automatic spraying technology, which is applied in the direction of insulation/armored cable repair equipment, spraying devices, etc., can solve the problems of poor work reliability, low construction safety, slow speed, etc., and achieve the effect of reliable work and perfect automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

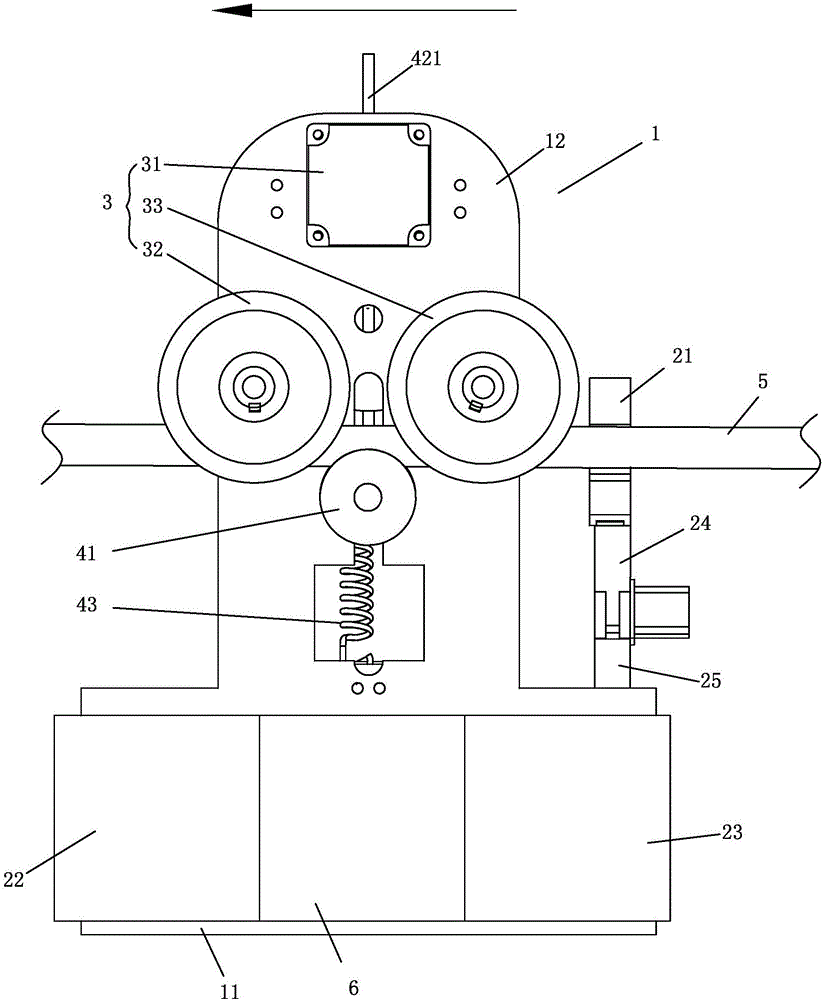

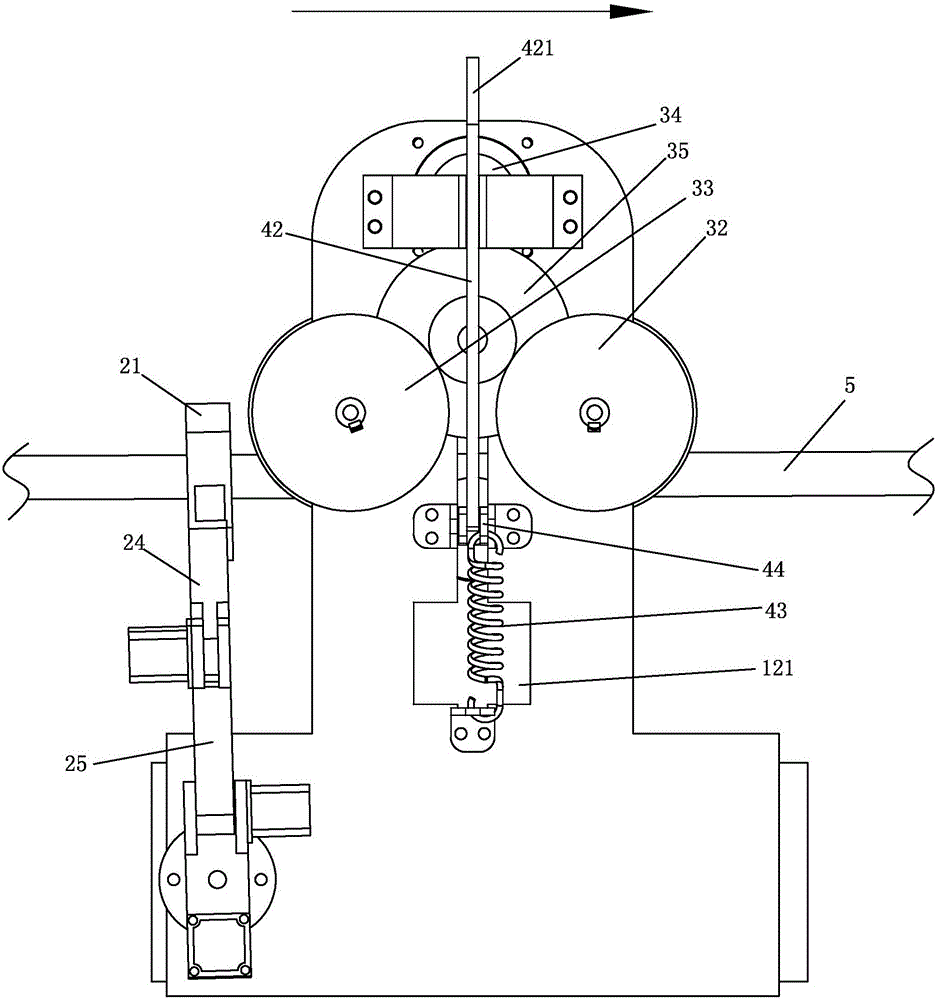

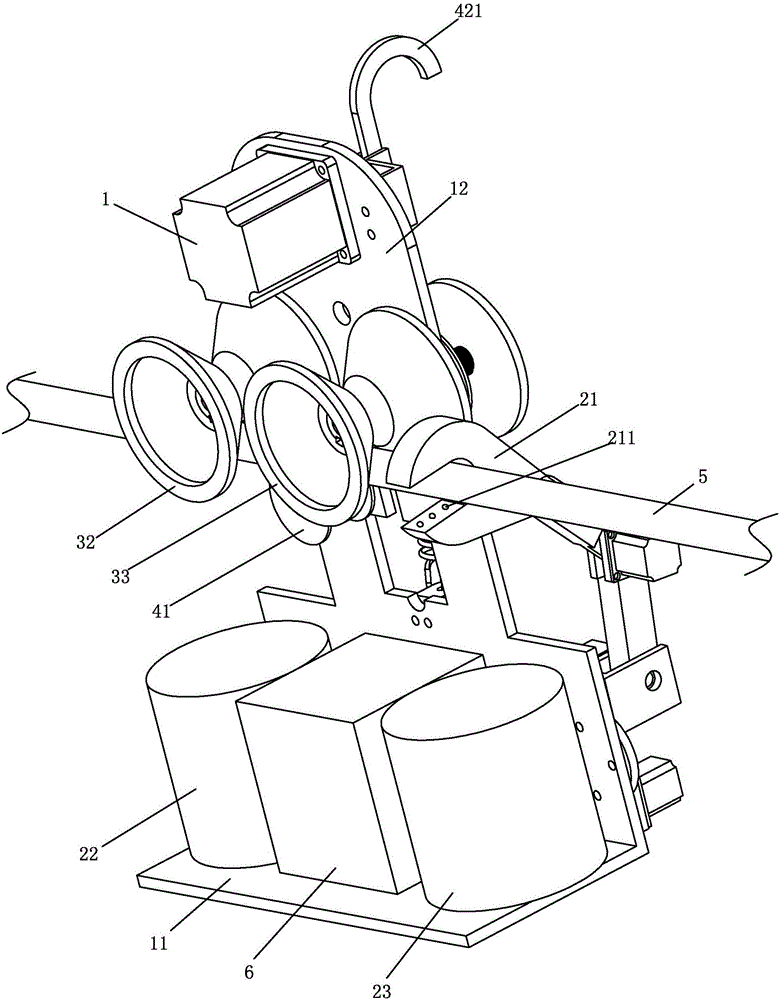

[0029] See Figure 1 to Figure 4 As shown, a kind of overhead transmission line 5 automatic spraying equipment of the present invention comprises frame 1, spraying device 2, traveling device 3 and self-clamping device 4, and described spraying device 2, traveling device 3 and self-clamping device 4 Attached to the frame 1 respectively; the traveling device 3 includes traveling rollers 32, 33 and a driving motor 31, the traveling rollers 32, 33 are provided with grooves for clamping with the power line 5, and the driving motor 31 Drive the traveling rollers 32, 33 to roll along the upper side of the power line 5; the spraying device 2 includes a paint tank 23, a paint nozzle 21 and an air pressure tank 22, and the paint nozzle 21 is connected to the paint tank 23 , the air pressure tank 22 is connected with the paint tank 23 through a high-pressure air valve 26, and the paint nozzle 21 is matched with the power line 5; the clamping device includes a clamping roller 41, a pull r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com