Universal Dry Automatic Isostatic Press

An isostatic press, general-purpose technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of low degree of automation, poor versatility of dry isostatic presses, affecting product quality, etc., to achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

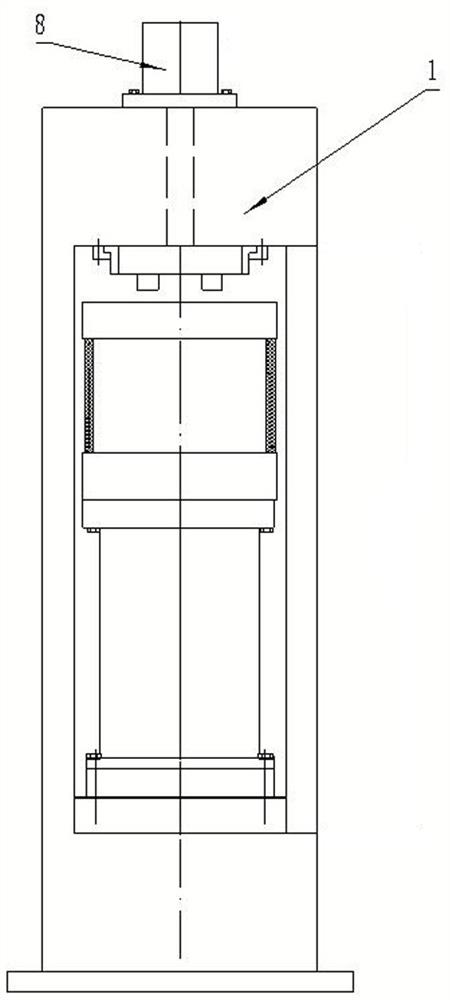

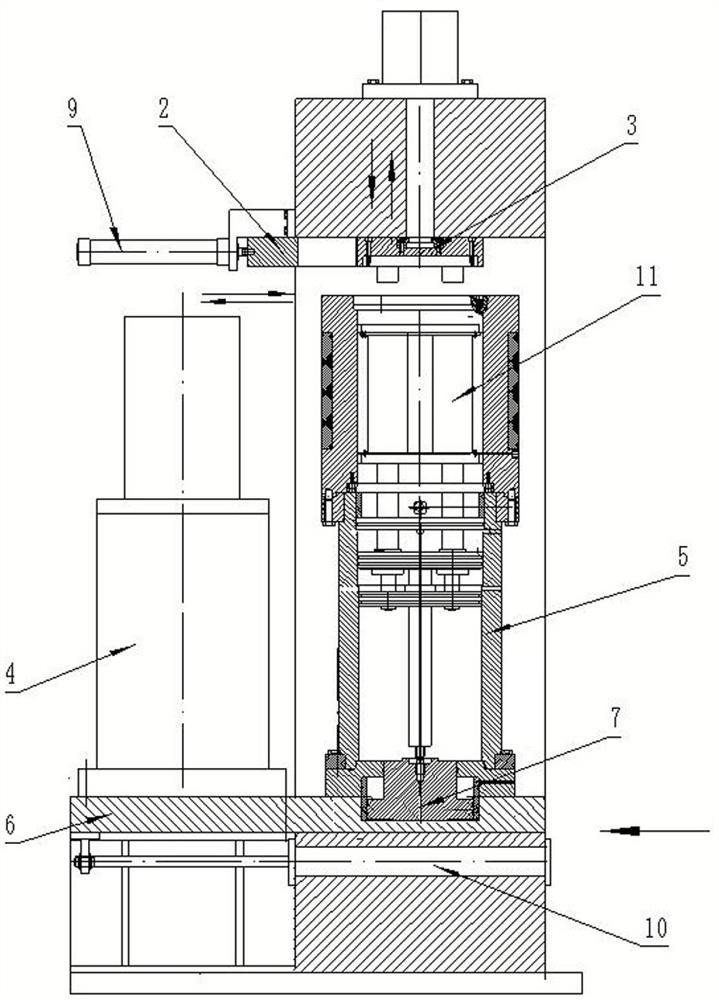

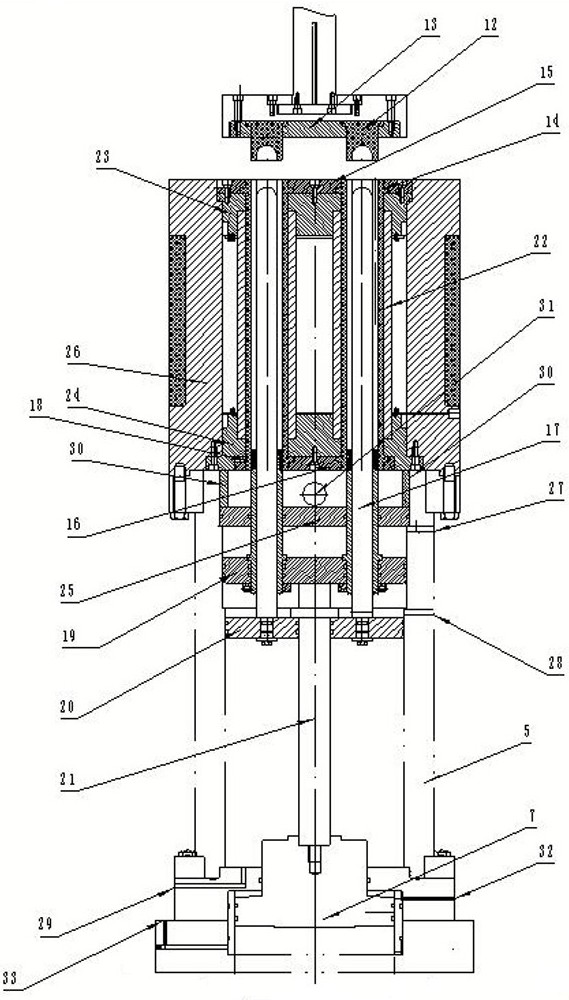

[0023] Such as figure 1 , figure 2 , Figure 4 As shown, the general-purpose dry automatic isostatic press includes a frame 1, a molding assembly positioned on the frame, and an upper mold 12 driven by an upper mold driving cylinder 8 positioned on the top of the frame; The high-pressure chamber assembly 11, the barrel-shaped (upper open) high-pressure chamber seat 5 and the balance oil cylinder 7 are composed successively. The piston rod of the balance oil cylinder 7 passes through the bottom of the barrel-shaped high-pressure chamber seat 5 and extends into the high-pressure Inside the chamber seat 5; the high-pressure chamber assembly 11 includes a cylindrical (both ends open) high-pressure chamber body 26, the lower end of the high-pressure chamber body 26 is sealed and movable with the upper end of the high-pressure chamber seat 5, and the center of the high-pressure chamber body 26 The line coincides with or is parallel to the center line of the high-pressure cavity s...

Embodiment 2

[0035] Such as figure 1 , figure 2 , image 3 As shown, the general-purpose dry automatic isostatic press includes a frame 1, a molding assembly positioned on the frame, and an upper mold 12 driven by an upper mold driving cylinder 8 positioned on the top of the frame; The high-pressure chamber assembly 11, the barrel-shaped (upper open) high-pressure chamber seat 5 and the balance oil cylinder 7 are composed successively. The piston rod of the balance oil cylinder 7 passes through the bottom of the barrel-shaped high-pressure chamber seat 5 and extends into the high-pressure Inside the chamber seat 5; the high-pressure chamber assembly includes a cylindrical (both ends open) high-pressure chamber body 26, the lower end of the high-pressure chamber body 26 is sealed and movable with the upper end of the high-pressure chamber seat 5, and the center line of the high-pressure chamber body 26 Coincident with or parallel to the centerline of the high-pressure cavity seat 5, a cy...

Embodiment 3

[0042] Such as Figure 13 As shown, the general-purpose dry automatic isostatic press includes a frame 1, a molding assembly positioned on the frame, and an upper mold 12 driven by an upper mold driving cylinder 8 positioned on the top of the frame; The high-pressure chamber assembly 11, the barrel-shaped (upper open) high-pressure chamber seat 5 and the balance oil cylinder 7 are composed successively. The piston rod of the balance oil cylinder 7 passes through the bottom of the barrel-shaped high-pressure chamber seat 5 and extends into the high-pressure Inside the chamber seat 5; the high-pressure chamber assembly includes a cylindrical (both ends open) high-pressure chamber body 26, the lower end of the high-pressure chamber body 26 is sealed and movable with the upper end of the high-pressure chamber seat 5, and the center line of the high-pressure chamber body 26 Coincident with or parallel to the centerline of the high-pressure cavity seat 5, a cylindrical (both ends op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com