A kind of sn1-0.5xcuxs2 nano flower and its preparation and application

A technology of nanoflowers and nanosheets, applied in other chemical processes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex preparation process and poor performance of finished products, and achieve high carrier mobility, Good prospects for industrialization promotion, and the effect of simple reaction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 2.488mmol crystalline tin tetrachloride (SnCl 4 ·5H 2 O), 0.0249mmol copper chloride dihydrate (CuCl 2 2H 2 O), 5mmol thioacetamide (CH 3 CSNH 2 ) and 30mL ethanol, stir until the solution is clear, take out the stirring bar, put the inner liner into the reaction kettle, keep it in a constant temperature oven at 180°C for 12h, stop heating, cool to room temperature in the oven, centrifuge, and use deionized water After washing with ethanol three times each, dry in a constant temperature drying oven at 60°C to obtain a product marked as Sn 1-0.5x Cu x S 2 -1, (x=0.01) was used for subsequent analysis. The diameter of the product nanoflower is about 3μm, and the specific surface area is 68㎡ / g.

Embodiment 2

[0040] Add 2.2 mmol of crystalline tin tetrachloride (SnCl 4 ·5H 2 O), 0.56mmol copper chloride dihydrate (CuCl 2 2H 2 O), 5mmol thioacetamide (CH 3 CSNH 2 ) and 30mL ethanol, stir until the solution is clear, take out the stirring bar, put the inner liner into the reaction kettle, keep it in a constant temperature oven at 180°C for 12h, stop heating, cool to room temperature in the oven, centrifuge, and use deionized water After washing with ethanol three times each, dry in a constant temperature drying oven at 60°C to obtain a product marked as Sn 1-0.5x Cu x S 2 -2, (x=0.25) was used for subsequent analysis and characterization. The diameter of the product nanoflower is about 5μm, and the specific surface area is 70㎡ / g.

Embodiment 3

[0042] Add 2.25 mmol crystalline tin tetrachloride (SnCl 4 ·5H 2 O), 0.5mmol copper chloride dihydrate (CuCl 2 2H 2 O), 5mmol thioacetamide (CH 3 CSNH 2 ) and 30mL of ethanol, put in a stirrer and stir until the solution is clear, take out the stirrer, put the lining in the reaction kettle and keep it in a constant temperature oven at 180°C for 12h. After stopping the heating, cool it to room temperature in the oven, centrifuge, and After washing with deionized water and ethanol three times respectively, dry in a constant temperature drying oven to obtain the product Sn 1-0.5x Cu x S 2 -3, (x=0.2) was used for subsequent analysis and characterization. The diameter of the product nanoflower is about 3μm, and the specific surface area is 73.45㎡ / g.

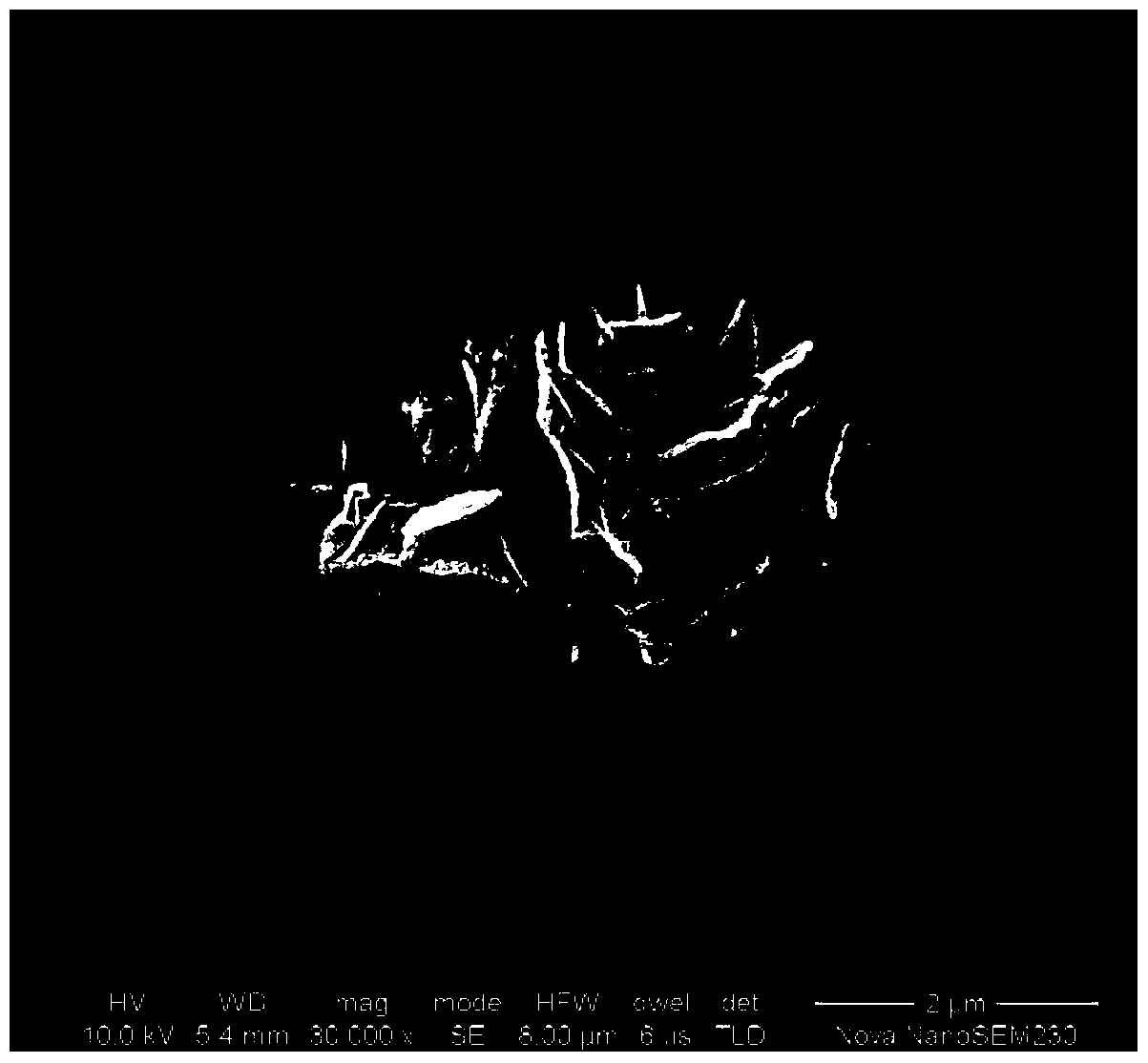

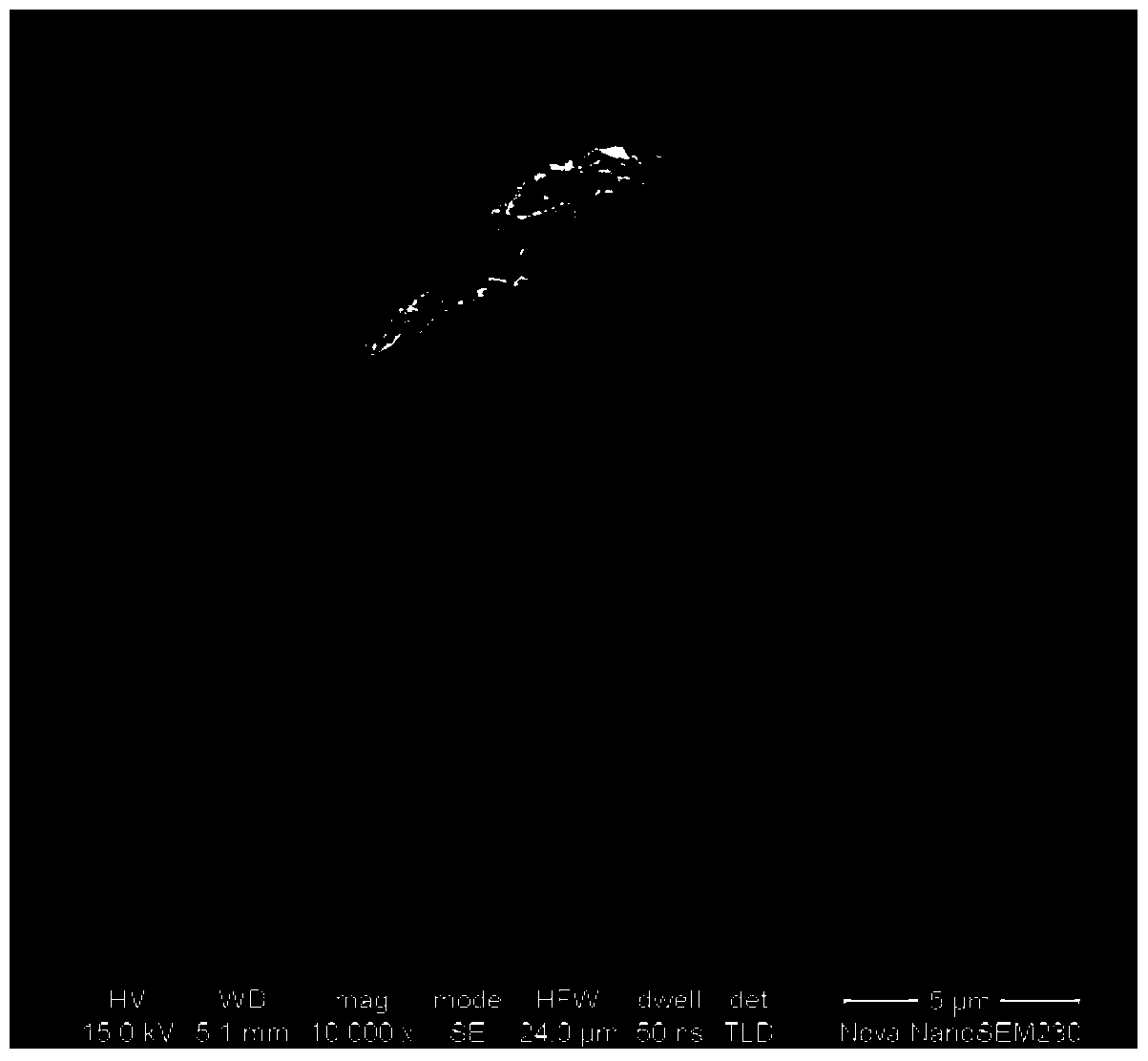

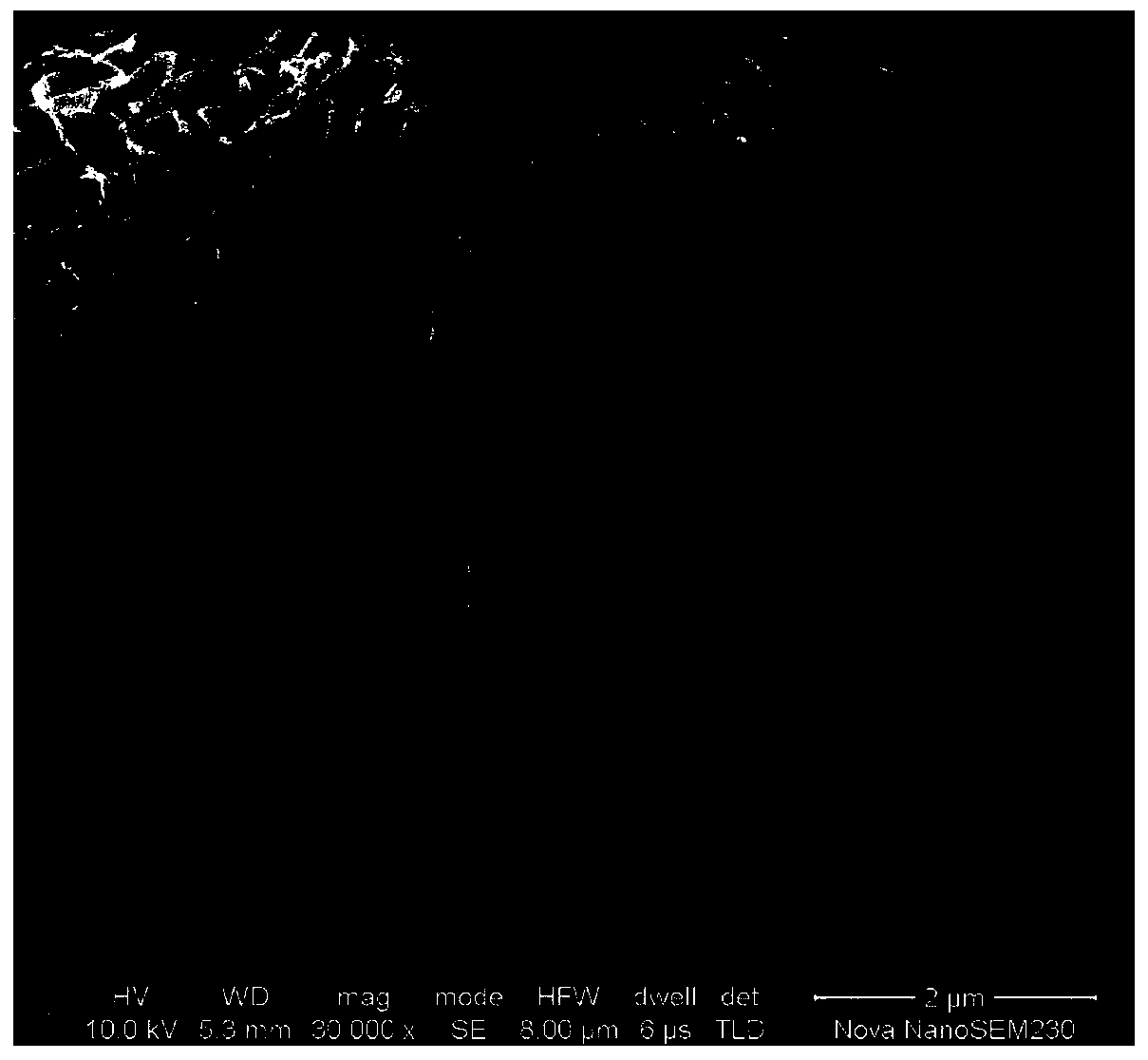

[0043] The sample Sn 1-0.5x Cu x S 2 -1, Sn 1-0.5x Cu x S 2 -2 and Sn 1-0.5x Cu x S 2 -3 Use scanning electron microscopy (SEM) to characterize the morphology, size, etc. of the prepared samples, the results are as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com