Ceramic bi-directional scraper bit and processing method thereof

A processing method and a cutting head technology, applied in the field of kitchen utensils, can solve the problems of poor wear resistance of stainless steel, affecting the quality of fruits and vegetables, and affecting physical health, and achieve the effects of easy equipment, improved convenience, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

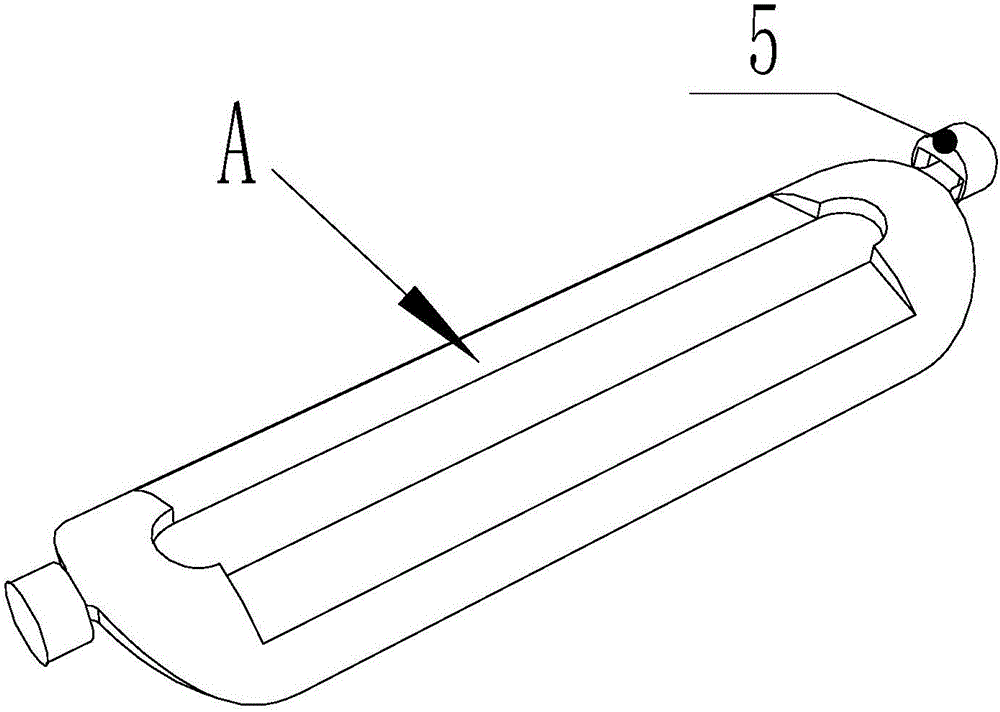

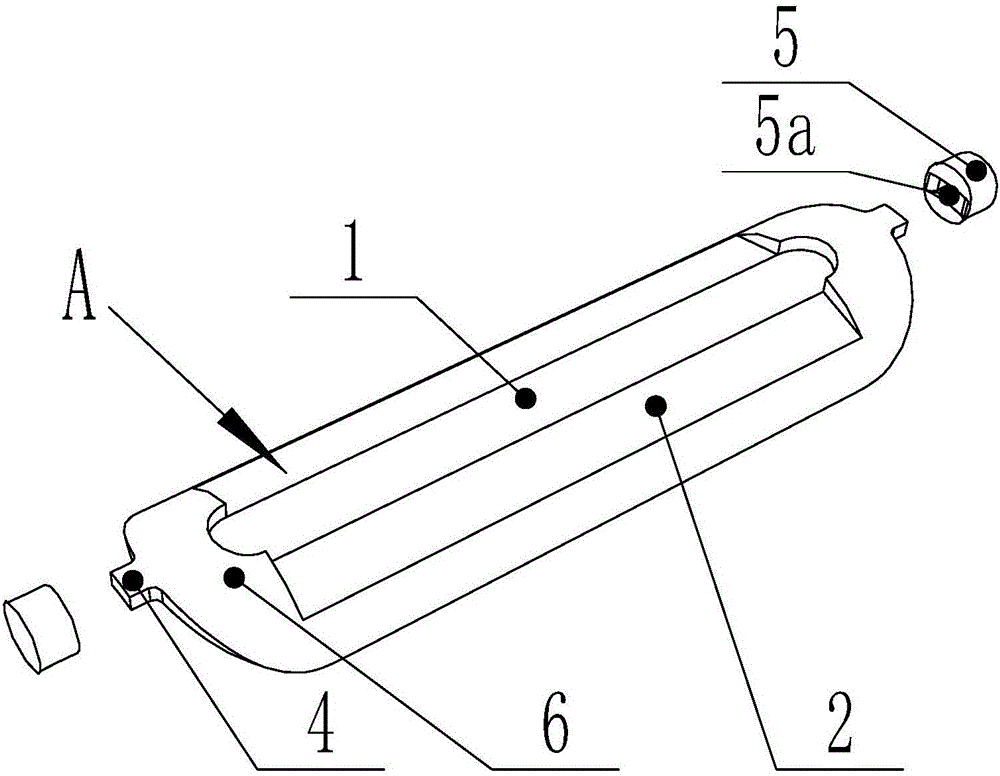

[0029] Such as Figure 1-2 As shown, a ceramic two-way scraper cutter head includes a cutter head body A integrally formed by ceramic materials, and a cutter head protrusion 4 is respectively provided at both ends of the cutter head body A. 4 are respectively equipped with a cylindrical cutter head mounting block 5 that is compatible with it, and the cutter head protrusion 4 is a square shape, and the cutter head mounting block 5 is provided with a shape corresponding to the cutter head protrusion 4. The adapted concave 5a makes the cutter head body A stable and fixed, and the cylindrical cutter head mounting block can be rotated on the handle of the scraping knife, which makes it easier to remove the skins of fruits and vegetables, and is convenient for people's actual use.

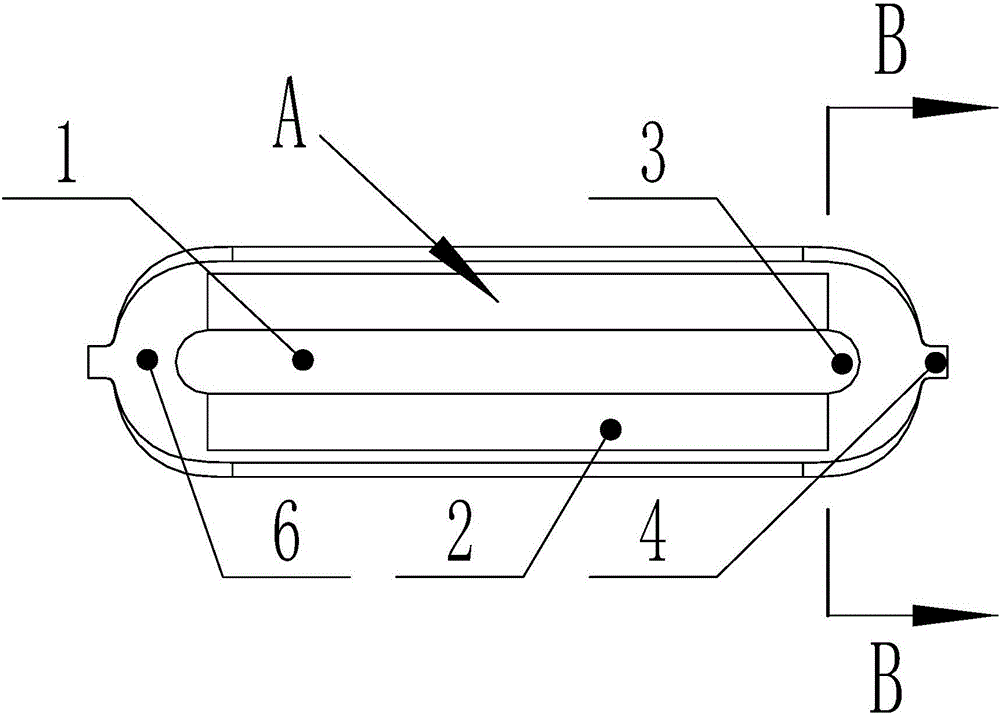

[0030] See image 3 and Figure 4 , the cutter head body A includes two fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com