Biomaterial having enhanced rubber properties through natural cross-linkage of collagen and hyaluronic acid, preparing method thereof, and using method thereof

A collagen and natural cross-linking technology, applied in cosmetic preparations, skin care preparations, medical preparations containing active ingredients, etc., can solve problems such as limitations, inability to achieve satisfactory dosage forms, and inability to provide manufacturing methods, etc. Achieve the effect of improving quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Manufacturing method of natural cross-linked rubber dosage form material using collagen and hyaluronic acid: Syringe mixing

[0086] 1. Purpose: To confirm the dosage form conditions using collagen and hyaluronic acid.

[0087] 2. Method: 1% (w / v) concentration of collagen solution and hyaluronic acid solution were prepared using raw materials respectively. Mix each raw material at a ratio of 1:2 to 9:1 (collagen:hyaluronic acid). The solution filled in the injection device is connected with a connector, and the production state of the rubber dosage form is checked during bidirectional mixing. The hyaluronic acid used at this time has a molecular weight of 1,000Kda.

[0088] 3. Results: Under the condition that the concentration of each raw material is 1%, the natural cross-linked substance produced under the mixing condition of 2:1 to 7:1 is a substance with rubber properties. Among them, the ratio of 3:1 is the best condition. Under these conditions, a dosage form...

Embodiment 2

[0090] Manufacturing method of natural cross-linked rubber dosage form using collagen and hyaluronic acid: centrifugation

[0091] 1. Purpose: To confirm the manufacturing method required for the mass production of collagen and hyaluronic acid.

[0092] 2. Method: 1% (w / v) concentration of collagen solution and hyaluronic acid solution were prepared using raw materials respectively. Mix the ingredients in a ratio of 3:1 (collagen:hyaluronic acid). By shocking the solution by applying high energy during mixing, lumps will form. After removing the solution other than the above-mentioned lumps, the lumps are concentrated and sufficiently dehydrated by a centrifugation method, thereby producing a rubber dosage form substance.

Embodiment 3

[0094] Manufacturing method of natural cross-linked rubber dosage form using collagen and hyaluronic acid: Blender

[0095] 1. Purpose: To confirm the manufacturing method required for the mass production of collagen and hyaluronic acid.

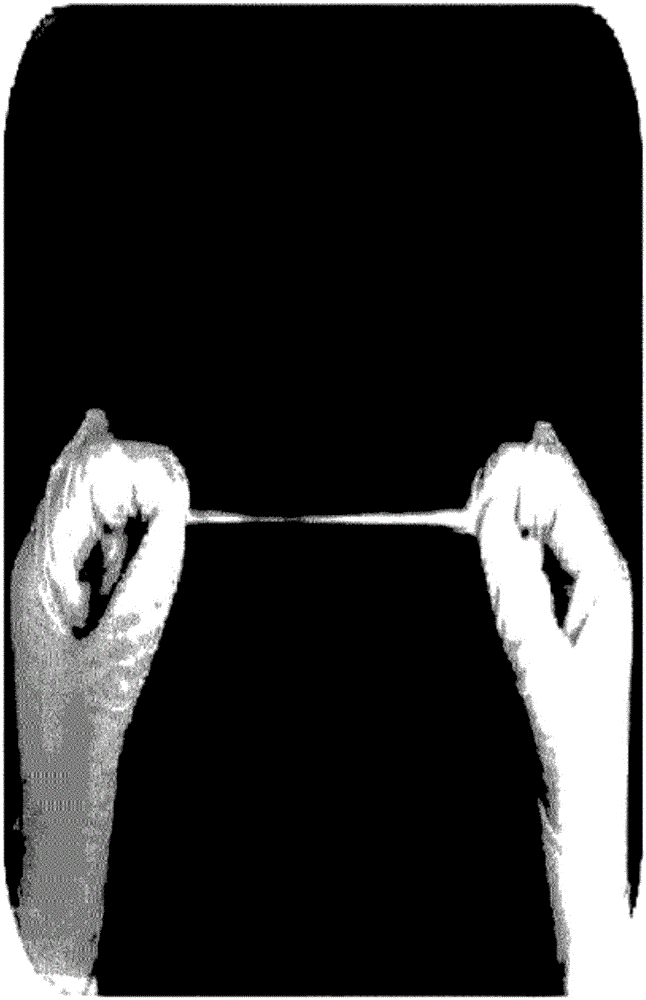

[0096] 2. Method: Use a blender to mix collagen and hyaluronic acid at a ratio of 3:1 and layer them, then sieve to remove moisture and then use a blender to increase its flexibility. The steps of manufacturing the dosage form are shown in Fig. 11(a)(b)(c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com