Power distribution automation cabinet

A technology of automation cabinets and cabinets, which is applied in the direction of electrical components, pull-out switch cabinets, panel/switch station circuit devices, etc., which can solve the problems of structural improvement of automated intelligent terminals, failure to achieve high standardization and modularization, and reduction of power outage time, etc. problems, to achieve the effect of centralized protection and convenient protection of the use environment, improvement of versatility and interchangeability, and convenient control of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail and completely below in conjunction with the embodiments and accompanying drawings.

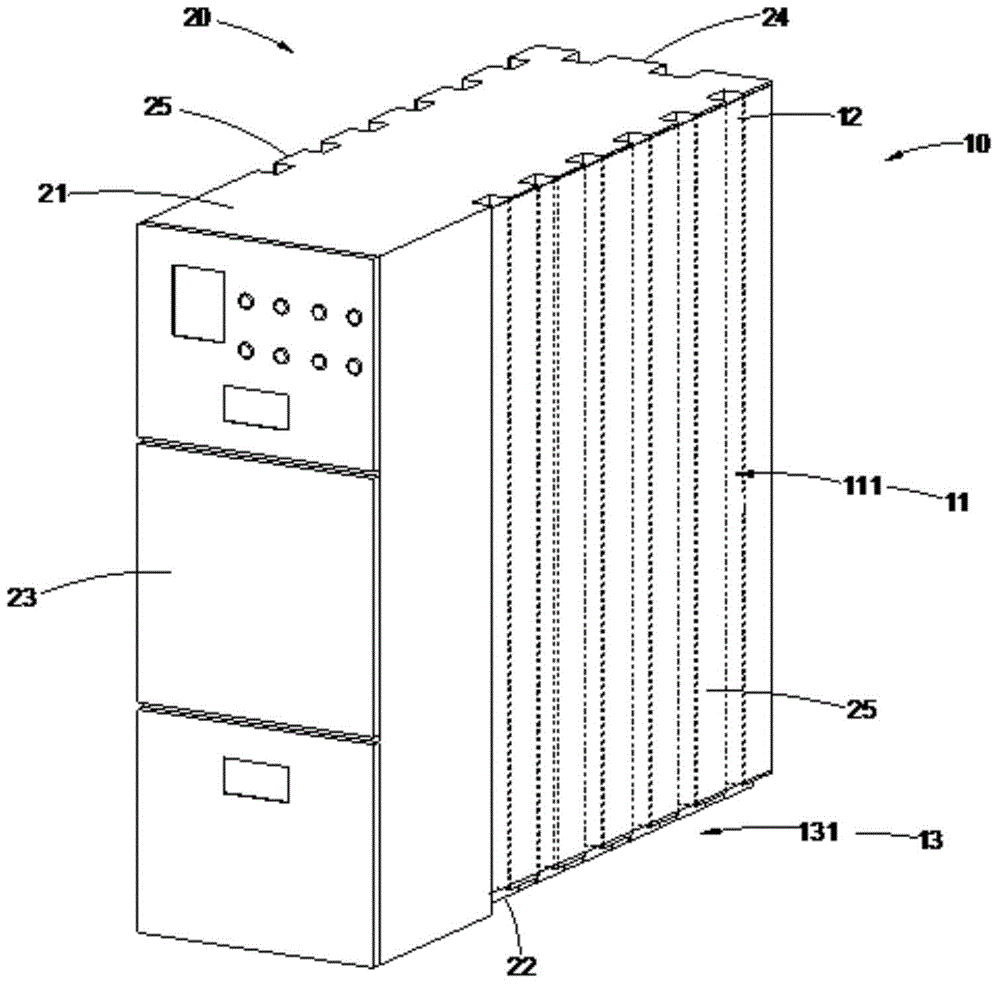

[0046] Such as figure 1 As shown, the outdoor switching station is divided into two functional areas, which are composed of several primary equipment areas or incoming and outgoing line areas A and a power distribution automation cabinet 2 (ie secondary equipment area or control area B) and placed in a shell Made within 3. The distribution automation cabinet includes a cabinet body and multiple drawer cabinets. The cabinet body and the drawer cabinets are movably connected, and the drawer cabinets are located in the cabinet. There are multiple functional modules on the distribution automation cabinet. Drawer-type assembly is used in the cabinet to form a drawer unit module. The cabinet body and the drawer-type cabinet are preferably plug-in electrical connections. At this time, when a functional module fails, the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com