Multi-wavelength tunable laser based on polarization-maintaining chirped phase-shift fiber grating

A technology of phase-shifting fiber grating and chirped fiber grating, which is applied in the field of optical fiber communication and instrumentation, and can solve the problems of high cost and high cost of laser system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

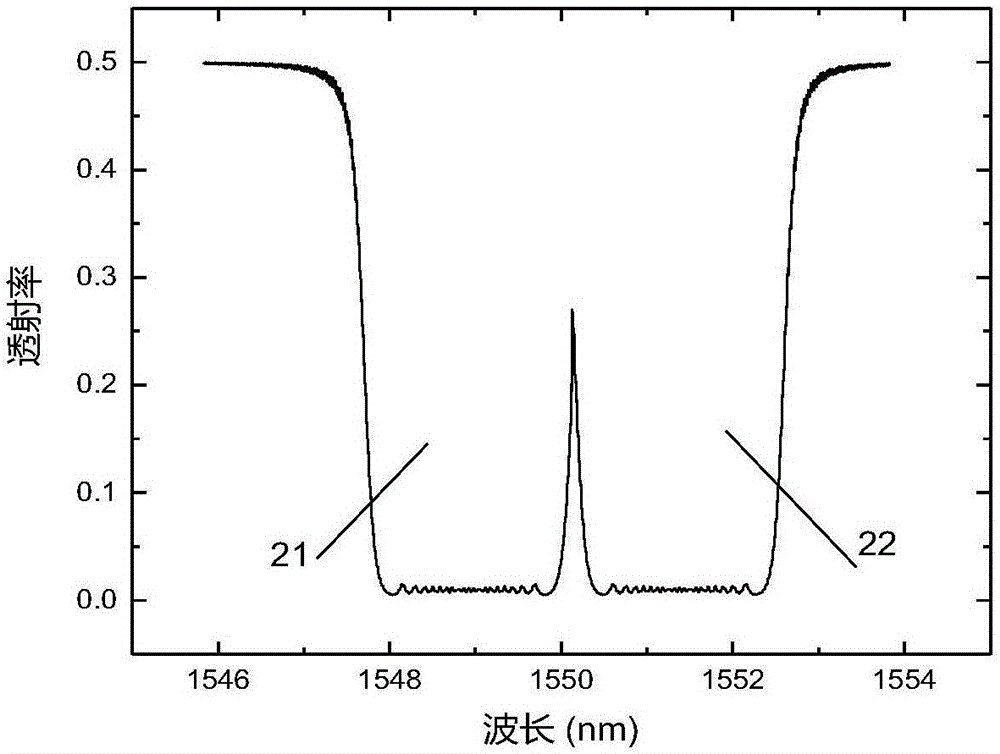

Embodiment 1

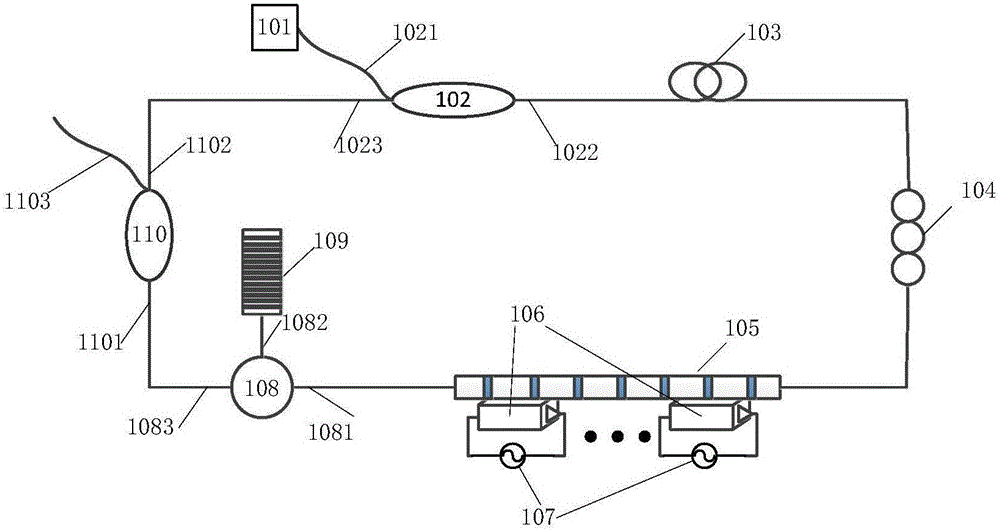

[0027] The laser includes a pumping light source 101, a wavelength division multiplexer 102, a doped fiber 103 with a length of 2 meters, a polarization controller 104, a polarization-maintaining chirped fiber grating 105, a piezoelectric ceramic 106, an electrical signal generator 107, and an optical ring. shaper 108, polarization maintaining uniform fiber grating 109, fiber 90:10 coupler 110. The specific link method is:

[0028] The pump light source 101 is connected to the first port 1021 on the left side of the wavelength division multiplexer 102, and the port 1022 on the right side of the wavelength division multiplexer 102 is connected to one end of a doped optical fiber 103 with a length of 2 meters. The other end of the miscellaneous fiber 103 is connected to one end of the polarization controller 104 , and the other end of the polarization controller 104 is connected to a polarization-maintaining chirped fiber grating 105 .

[0029] One side of the piezoelectric cer...

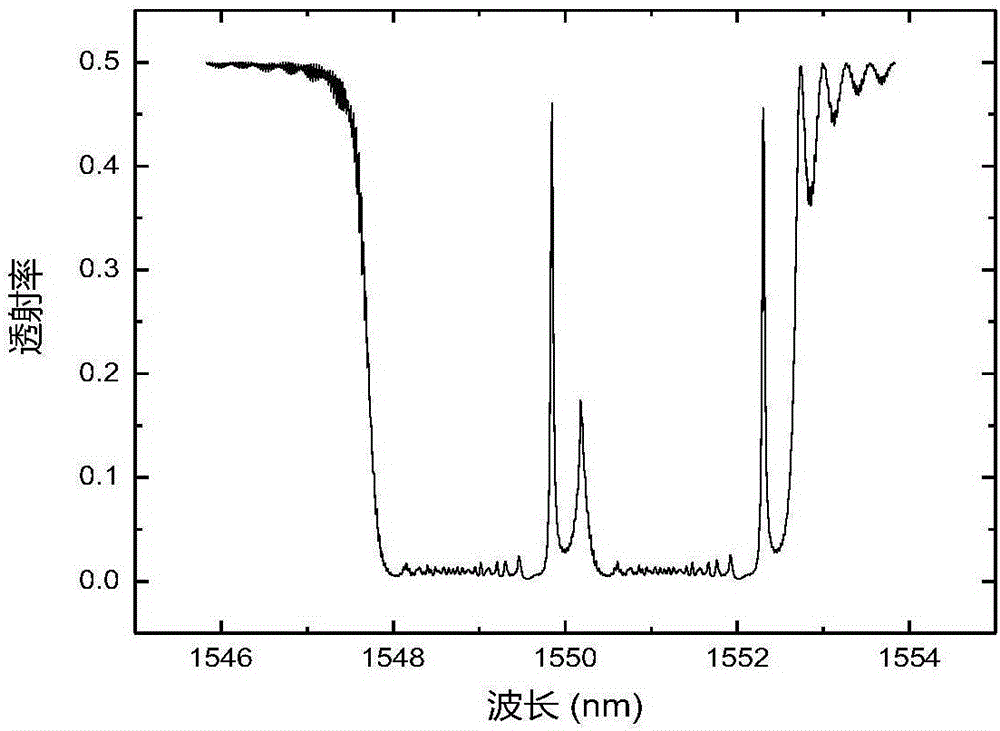

Embodiment 2

[0036] The laser includes a pumping light source 101, a wavelength division multiplexer 102, a doped fiber 103 with a length of 2 meters, a polarization controller 104, a polarization-maintaining chirped fiber grating 105, a piezoelectric ceramic 106, an electrical signal generator 107, and an optical ring. shaper 108, polarization maintaining uniform fiber grating 109, fiber 90:10 coupler 110. The specific link method is:

[0037] The pump light source 101 is connected to the first port 1021 on the left side of the wavelength division multiplexer 102, and the port 1022 on the right side of the wavelength division multiplexer 102 is connected to one end of a doped optical fiber 103 with a length of 2 meters. The other end of the miscellaneous fiber 103 is connected to one end of the polarization controller 104 , and the other end of the polarization controller 104 is connected to a polarization-maintaining chirped fiber grating 105 .

[0038] One side of the piezoelectric cer...

Embodiment 3

[0045] The laser includes a pumping light source 101, a wavelength division multiplexer 102, a doped fiber 103 with a length of 2 meters, a polarization controller 104, a polarization-maintaining chirped fiber grating 105, a piezoelectric ceramic 106, an electrical signal generator 107, and an optical ring. shaper 108, polarization maintaining uniform fiber grating 109, fiber 90:10 coupler 110. The specific link method is:

[0046] The pump light source 101 is connected to the first port 1021 on the left side of the wavelength division multiplexer 102, and the port 1022 on the right side of the wavelength division multiplexer 102 is connected to one end of a doped optical fiber 103 with a length of 2 meters. The other end of the miscellaneous fiber 103 is connected to one end of the polarization controller 104 , and the other end of the polarization controller 104 is connected to a polarization-maintaining chirped fiber grating 105 .

[0047] One side of the piezoelectric cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com