Sampling apparatus of chromatographic effect eliminating type ultra-high vacuum chamber for high-pressure gas

An ultra-high vacuum, high-pressure gas technology, applied in electrical components, sample introduction/extraction, parts of particle separator tubes, etc., can solve problems such as affecting product signal, shortening molecular mean free path, easy to break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

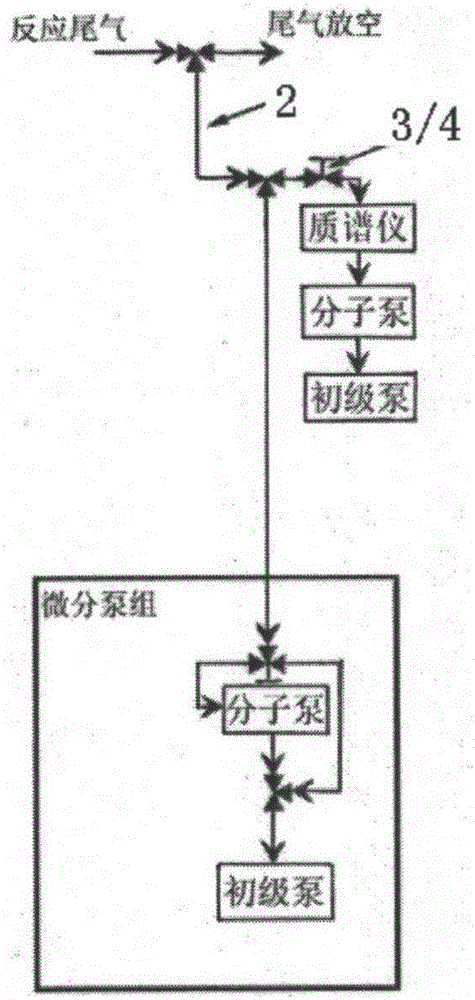

[0021] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

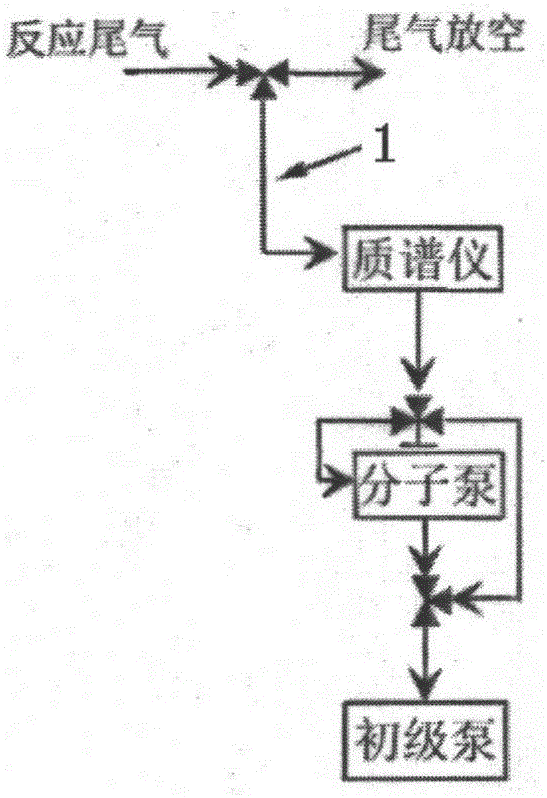

[0022] The present invention self-assembles the mass spectrometer in the laboratory implementation, and adopts imported PfeifferPrismaPlus electric quadrupole to match two PfeifferHiCube80KF interface molecular pump groups as a platform for testing the device of the present invention. The background air pressure is 5×10 when it is closed. -8 torr.

[0023] For related technical problems, the present invention has done the following considerations in design:

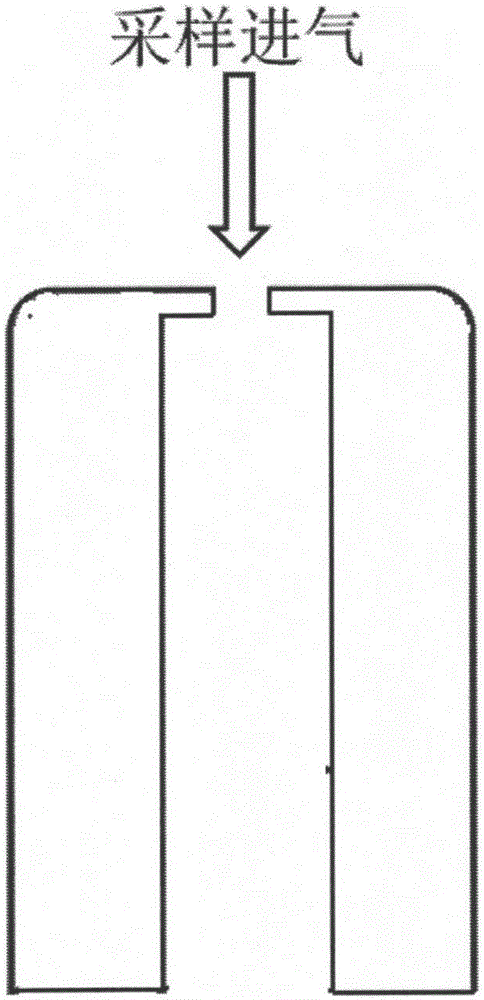

[0024] Firstly, the stainless steel capillary 2 is adopted, which is convenient for processing and refitting on the pipeline. At the same time, the airtightness of the sampling end in the high-pressure environment can be guaranteed through the common accessories of the pipeline, so as not to damage the working environment of the sampling end. Stainless steel capillary 2 use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com