Detection method and system for simulating wax deposition in crude oil pipeline conveying process

A detection method and pipeline transportation technology, applied in the investigation stage/state change, using material absorption and weighing, etc., can solve the problems of complex equipment, large floor area, high investment cost, etc., and achieve a good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

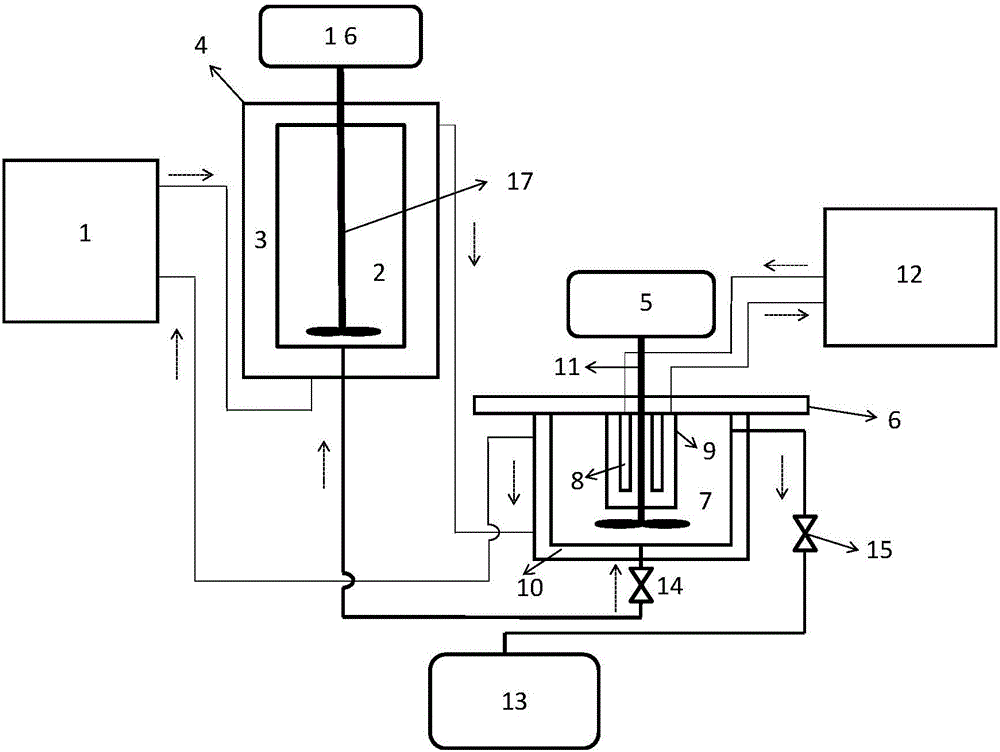

Image

Examples

Embodiment 1

[0071] The method for detecting wax deposition during the simulated crude oil pipeline transportation process of simulating the gathering and transportation trunk line of the Banbei block of Dagang Oilfield includes the following steps:

[0072] The crude oil from the Banbei block of Dagang Oilfield was used for wax deposition detection, and the specific working condition parameters are shown in Table 1.

[0073] Table 1 Detailed parameters of actual working conditions

[0074]

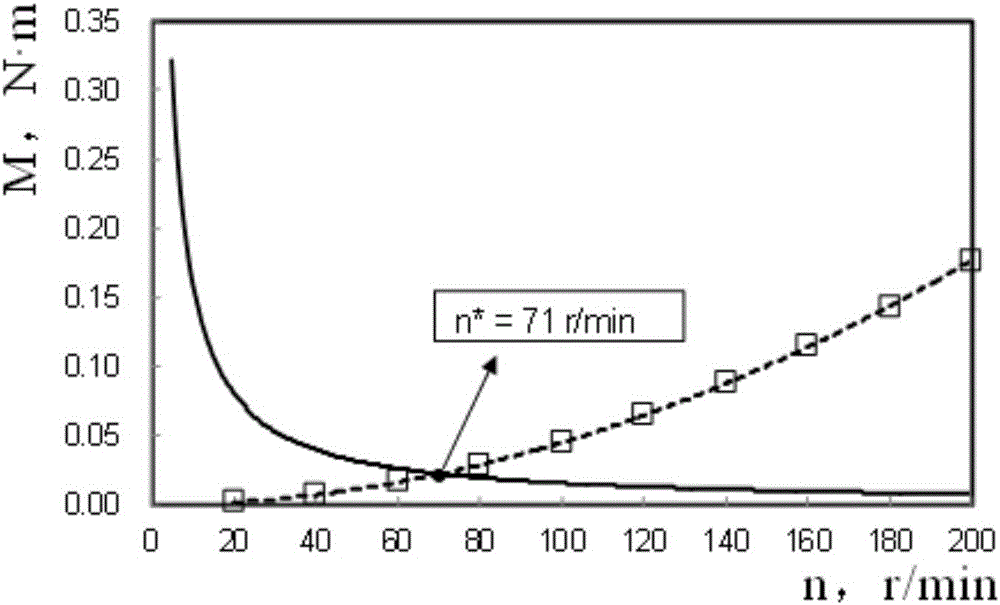

[0075] According to formula 1), under this working condition, the average shear rate of pipe flow shear is 4.26s -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com