Air cylinder with liquid buffer device

A buffer device and cylinder technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of piston and piston rod damage to cylinder, etc., and achieve the effect of slowing down collision and impact, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

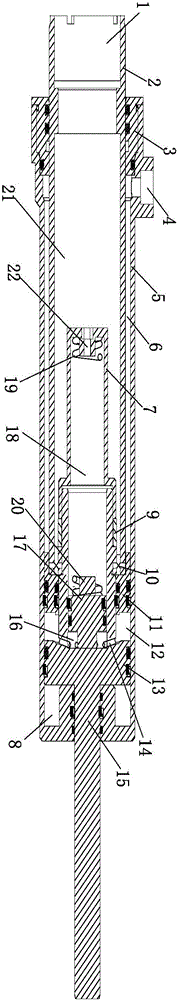

[0022] Such as figure 1 As shown, take the end where the thick piston rod 2 is located (ie the top in the figure) as the left direction, and the end where the thin piston rod 15 is located (ie the bottom in the figure) as the right direction.

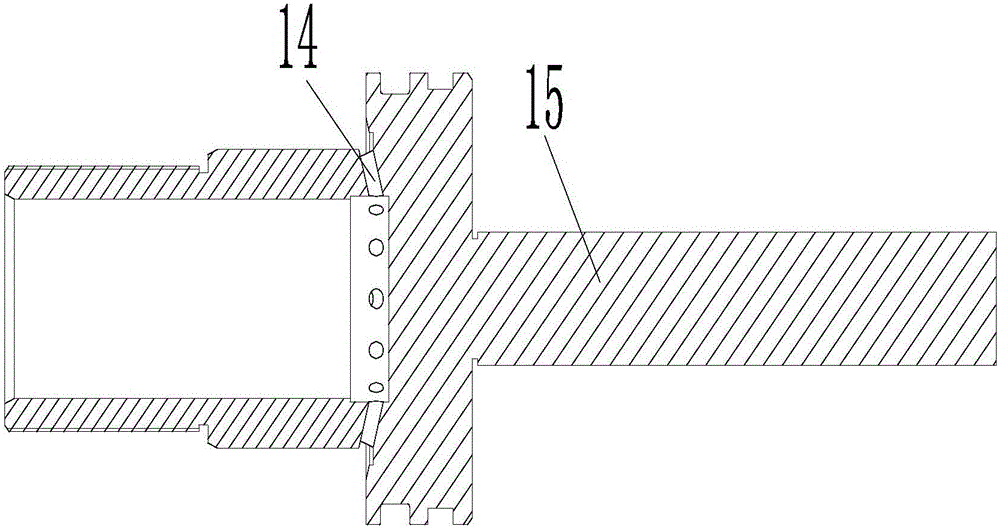

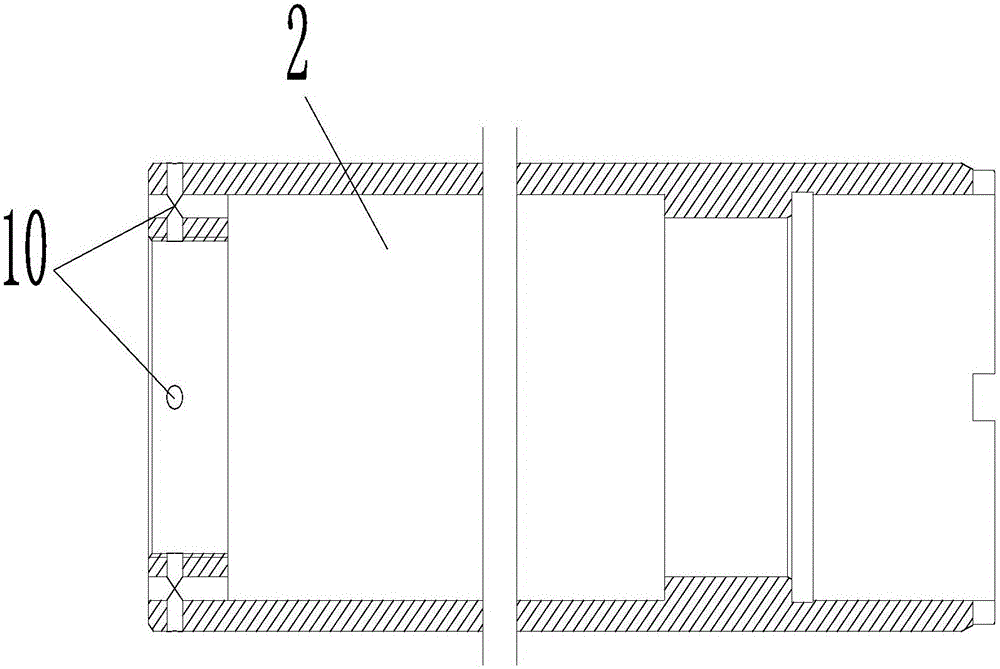

[0023] as attached Figure 1-3 As shown, a cylinder with a liquid buffer device includes a cylinder body 5 and a piston rod group slidably arranged in the cylinder body 5, and the piston rod group includes a thick piston rod 2 and a thin piston rod that are matched in thickness 15. The outer end of the thick piston rod 2 passes through the left end cover 3 of the cylinder body 5, the outer end of the thin piston rod 15 passes through the right end cover of the cylinder body 5, and the hollow thick piston rod 2 has an airtight first air cavity 21 , the inner end of the thin piston rod 15 passes through the inner end of the thick piston rod 2 and extends toward the first air cavity 21, and the thin piston rod 15 and the thick piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com