Novel refrigerating and heating double-functional machine

A cold and hot new technology, applied in the direction of coolers, household refrigeration devices, lighting and heating equipment, etc., can solve the problems of difficult refrigeration function of compressor components, many consumables, and underutilization of dual energy efficiency of compressor components, etc., to achieve structural Concise, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

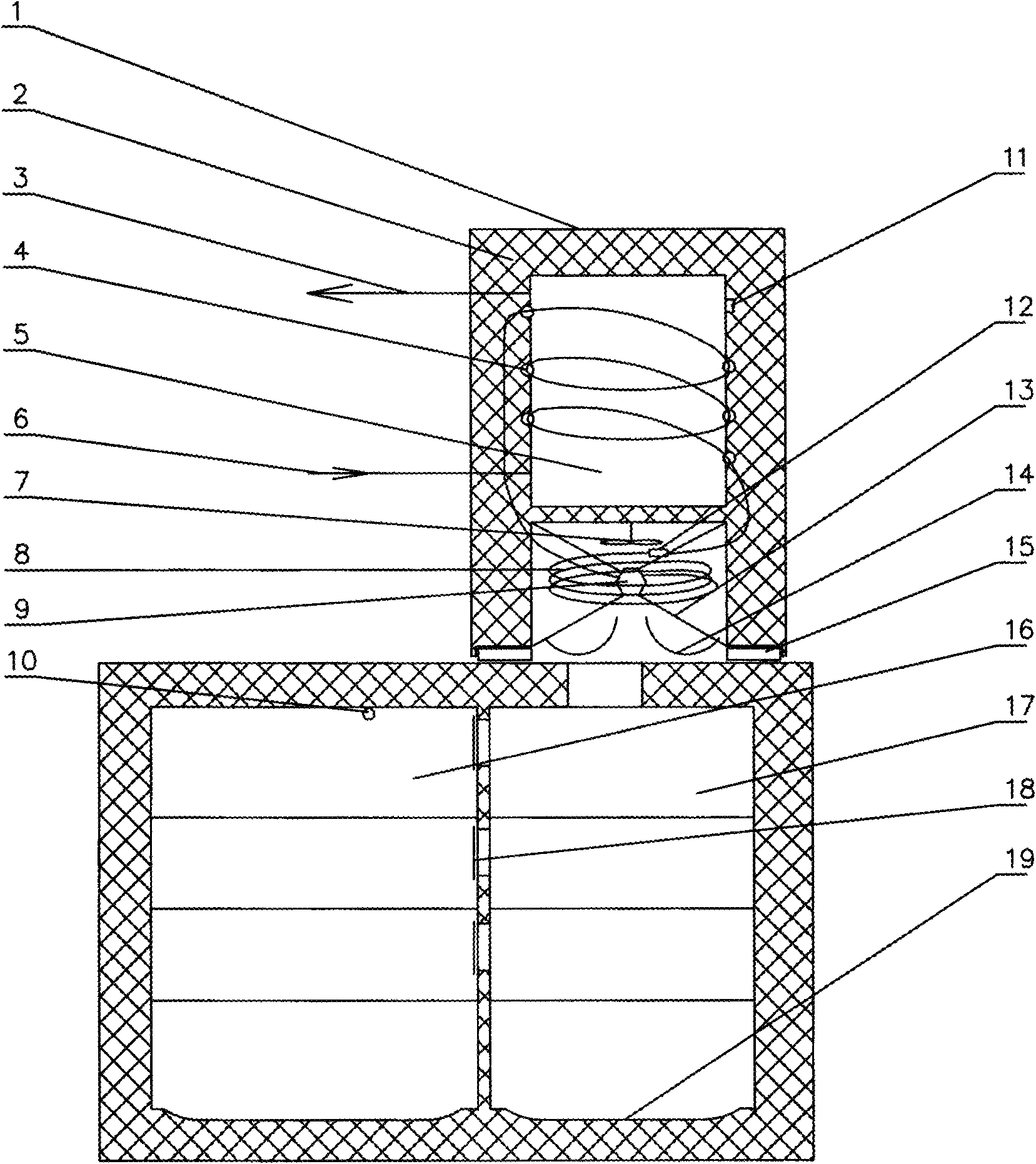

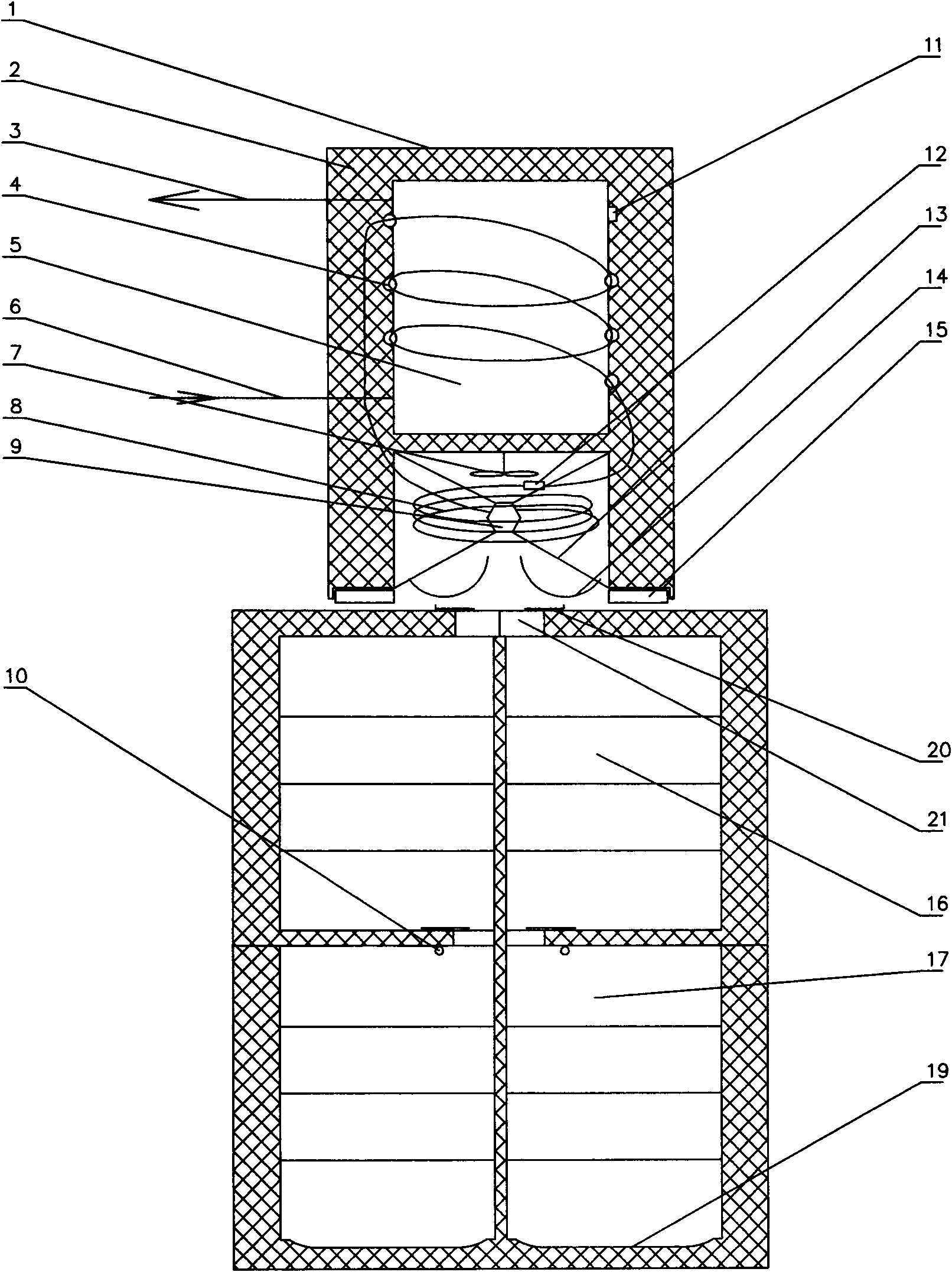

[0027] The present invention is mainly composed of energy collection box 1, freezer, control unit, small fan 7 and compressor components. Compressor components include compressor 9, accumulator, thermal expansion valve 12, coil, filter drier and refrigerant.

[0028] The energy collection box 1 of the present invention integrates compression, heat collection and refrigeration, and is located above the refrigerating cabinet 16. The upper part of the energy collection box 1 is a heat collection chamber, the lower part is a refrigeration chamber, and a hot water collection tank 5 is arranged in the heat collection chamber.

[0029] The compressor 9 is arranged in the middle of the refrigerating chamber and is obliquely pulled by two sets of springs 13 hooking the upper and lower ends of the refrigerating chamber wall.

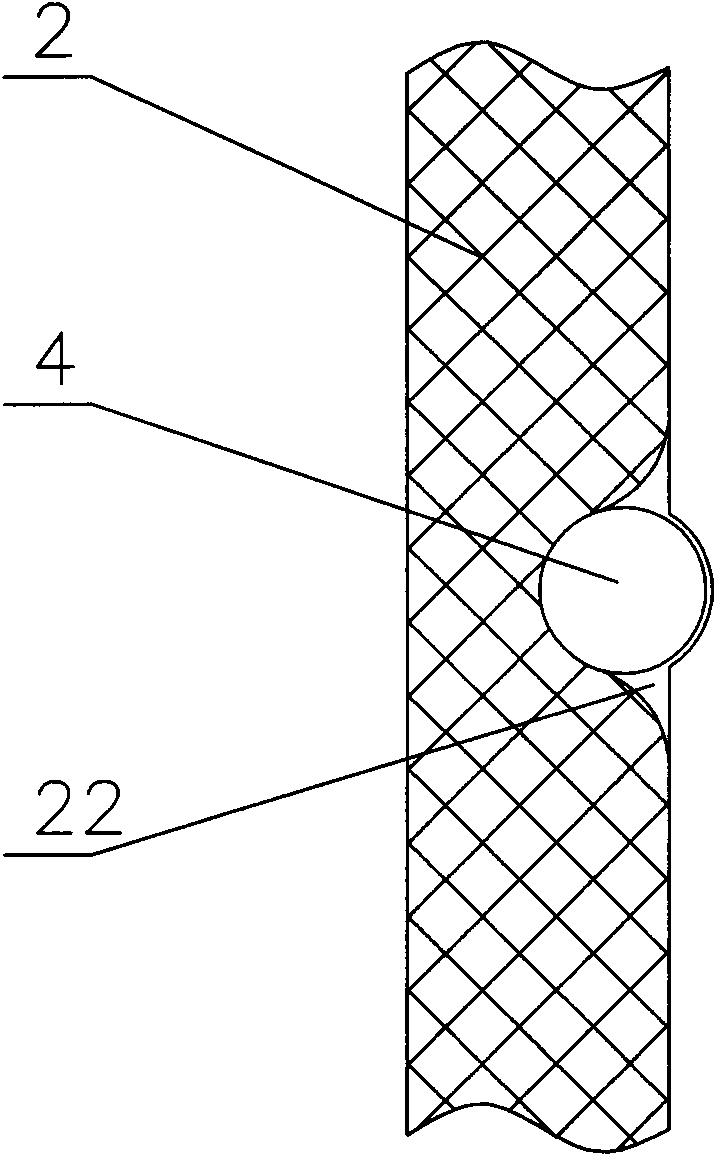

[0030] Each of the springs 13 is formed by connecting two springs 13 with different diameters.

[0031] An electric heater 11 and a temperature sensor 10 are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com