Pulse type exhaust turbocharging system for gas diesel engine

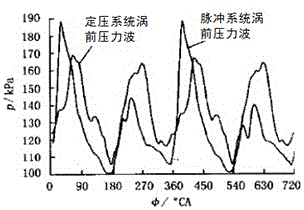

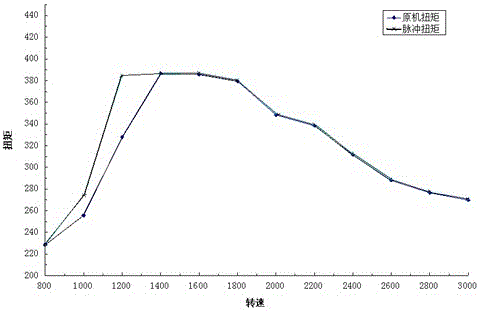

A technology of exhaust turbine and supercharging system, which is applied to combustion engines, internal combustion piston engines, mechanical equipment, etc., can solve problems such as insufficient utilization of exhaust pulse energy, and achieve the effects of simple structure, improved utilization, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiment of the present invention on the four-cylinder engine will be described in detail below in conjunction with the accompanying drawings. Based on the premise of the technical solution of the present invention, this embodiment provides detailed implementation and specific operation process, but the scope of protection of the present invention is not limited to Examples described below.

[0012] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

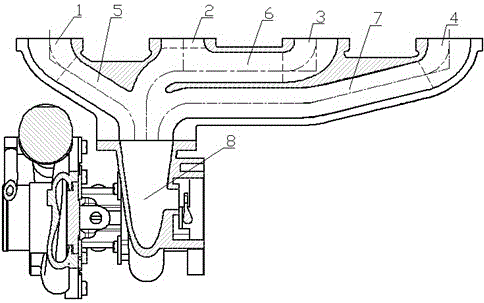

[0013] figure 1 As shown, the present invention includes: the fourth cylinder exhaust port (1), the third cylinder exhaust port (2), the second cylinder exhaust port (3), the first cylinder exhaust port (4), the fourth row The air pipe (5), the second exhaust pipe (6), the first exhaust pipe (7), the first cylinder exhaust port (4) are only connected to the first exhaust pipe (7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com