Multi-purpose metal powder repair machine

A technology of metal powder and repairing machine, which is applied in the coating process and coating of metal materials, can solve problems such as uneven repair, and achieve the effects of avoiding uneven repair, accurate position, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

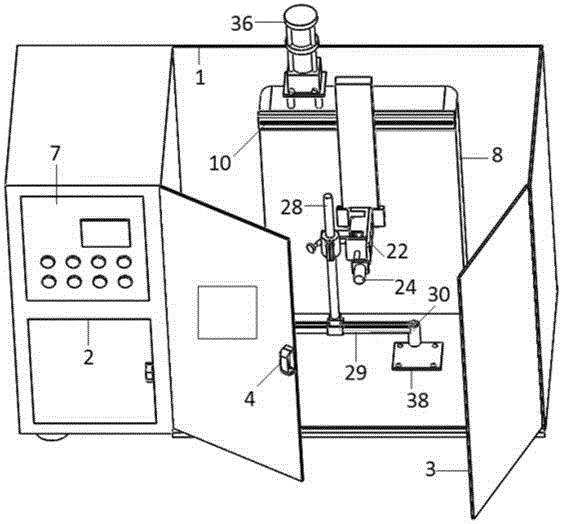

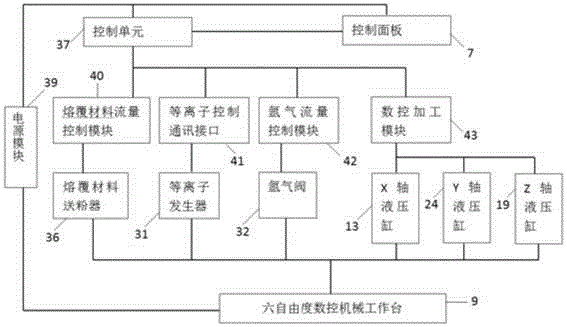

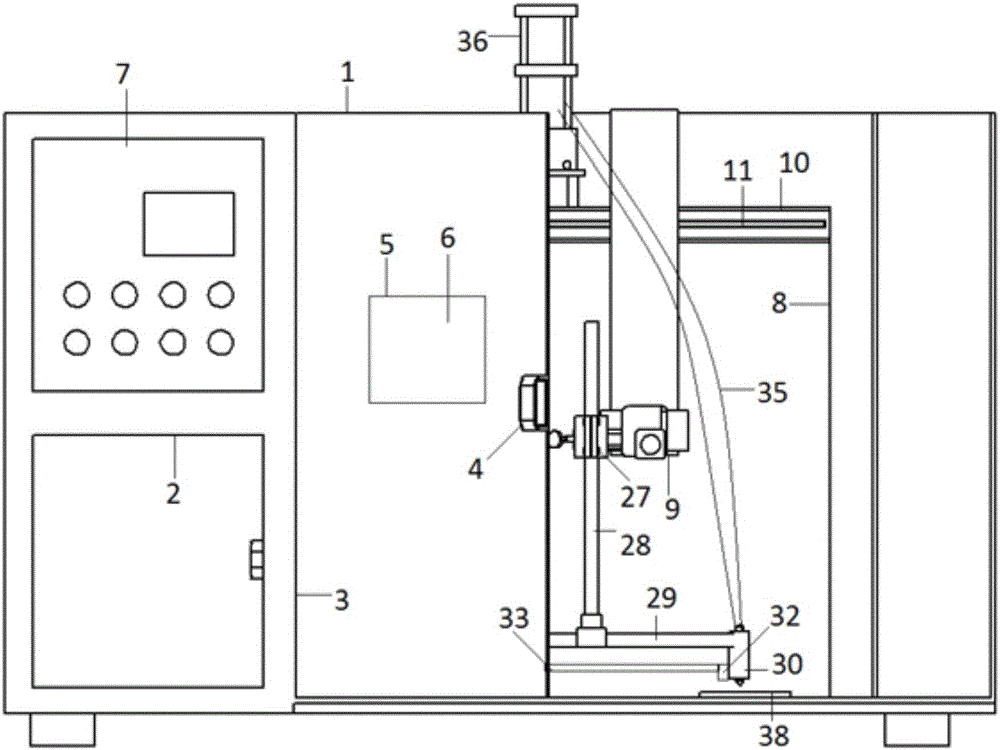

[0024] Specific implementation mode one: combine Figure 1-7As shown, it includes a casing 1, a control unit 37, and a power module 39. A lower box door 2 is arranged on the lower left side of the casing 1; a main box door 3 is arranged on the upper right side of the casing 1, and the side of the main box door 3 is connected 1 is hinged; the middle part of the other side of the main box door 3 is provided with a main box door handle 4, and the middle part of the main box door 3 is provided with an observation window 5; the inner frame of the observation window 5 is equipped with a goggle lens 6; the main box door 3 The rear inner wall is fixedly installed with a vertical fixed table 8; the upper left side of the shell 1 is provided with a control panel 7; the top of the vertical fixed table 8 is fixedly connected with a six-degree-of-freedom numerical control mechanical workbench 9; the rear bottom of the main box door 3 A horizontal workbench 38 is fixedly installed; a claddi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com