Environment-friendly phosphomolybdate anti-rust paint

An environmentally friendly technology of phosphomolybdate, which is applied in the direction of anti-corrosion coatings, coatings, polyester coatings, etc., can solve the problems of excessive heavy metals, achieve low additives, good manufacturing and construction environments, and excellent salt spray resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

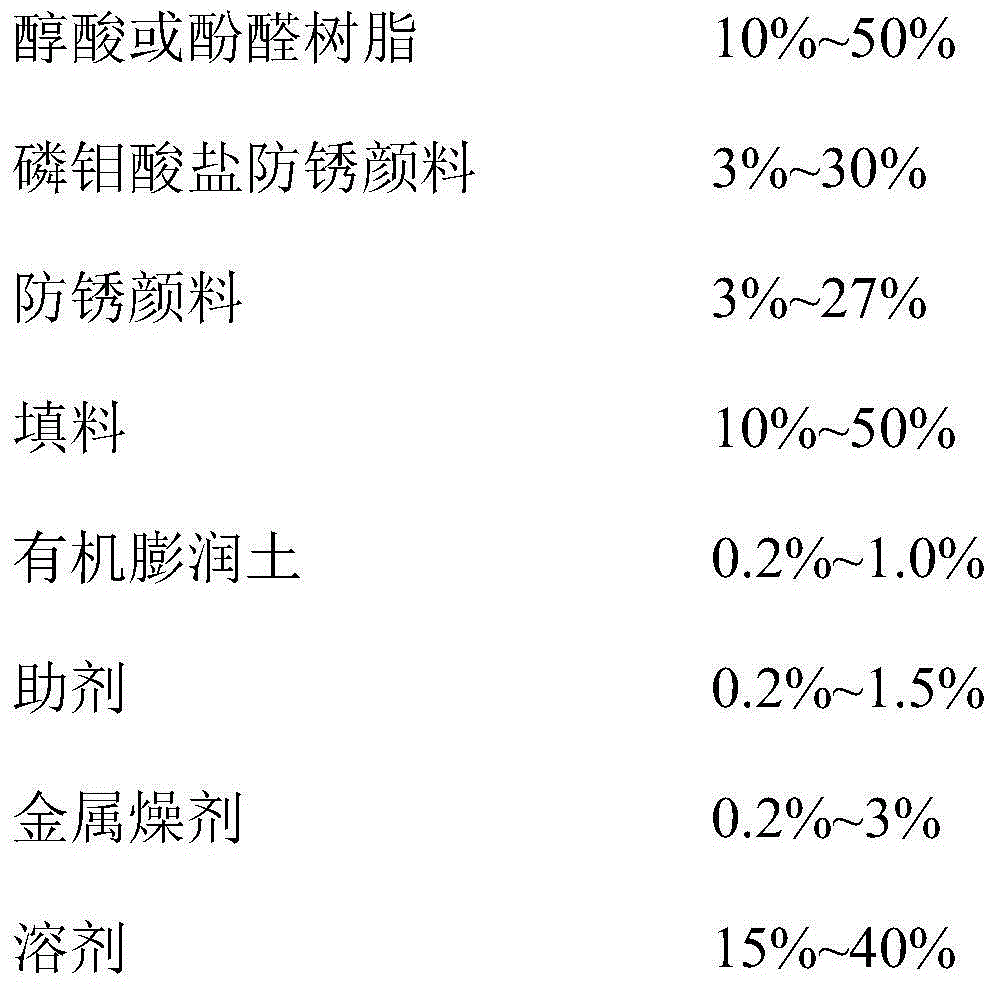

Method used

Image

Examples

Embodiment

[0025] Embodiment effect, 720 hours salt spray resistance test of antirust paint, test method:

[0026] The national standard "GB / T1771 Determination of neutral salt spray resistance of paints and varnishes" is used to conduct the salt spray test of the coating.

[0027] The content of zinc phosphomolybdate is 10% of the embodiment 1. After 720 hours of salt spray test, the performance is better than the alkyd red lead antirust paint. The alkyd red lead antirust paint model produces corrosion bubbles, while the new antirust paint The samples were not corroded. Embodiment 2, embodiment 3 all paint films are intact, and the surface is intact.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com