Yellowing-resistant water-based glaze, and preparation method and application thereof

A water-based and water-based resin technology, applied in coatings and other directions, can solve problems such as poor yellowing resistance, different colors of furniture, and deepening of the surface color of the illuminated parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

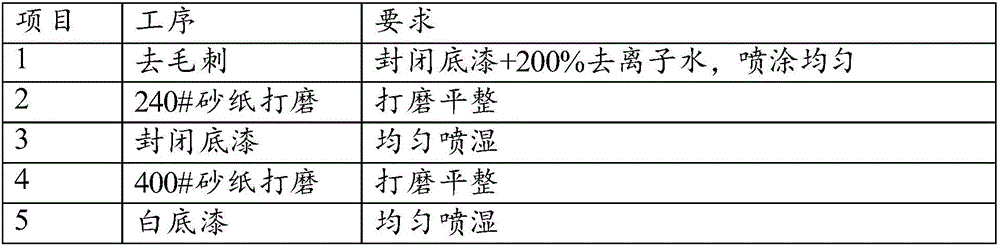

preparation example Construction

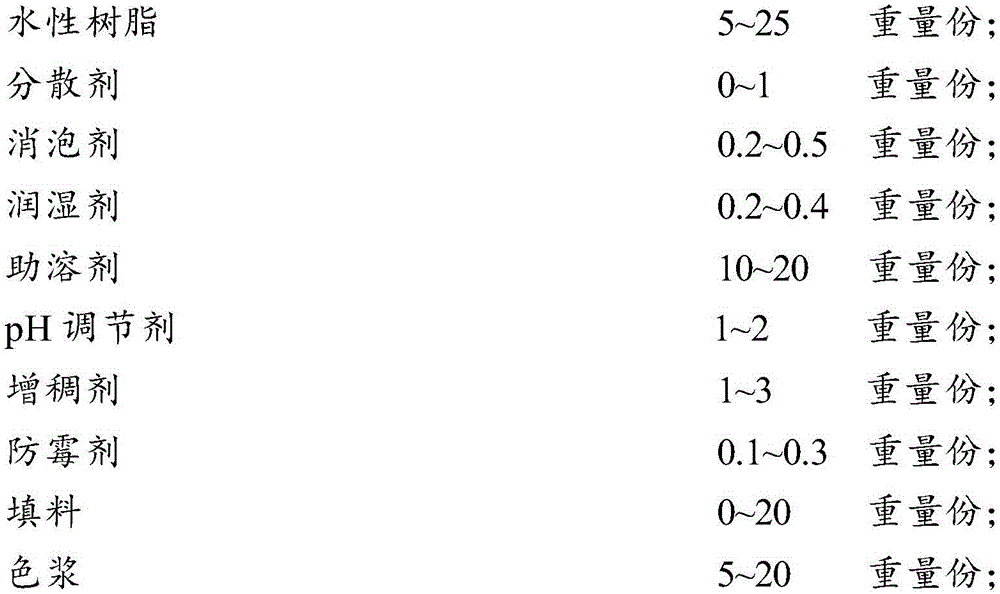

[0055] The present invention also provides a kind of preparation method of Water Grace, comprising the following steps:

[0056] 1) After mixing the water-based resin and water, mixture A is obtained;

[0057] After mixing the dispersant, defoamer, wetting agent, cosolvent and pH regulator, mixture B is obtained;

[0058] 2) Add the mixture B obtained in the above steps to the mixture A obtained in the above steps, and then add the filler to continue mixing to obtain the mixture C;

[0059] 3) Add a thickener, an antifungal agent and a color paste to the mixture C obtained in the above steps, and mix again to obtain the Water Gris.

[0060] In the preparation method of the present invention, the specific preferred scheme of the raw material, and the preferred numerical value of the number of parts added are consistent with the specific preferred scheme of the components in the aforementioned Water Gris, and the preferred numerical value of the number of added parts, and are n...

Embodiment 1

[0074] A kind of Water Grace comprises the following components according to mass percentage:

[0075] Alkali-swellable water-based resin emulsion (B-70): 15%, 5040: 1%, BYK028: 0.3%, propylene glycol 10%, AMP-95: 1.5%, tegowet270: 0.2%, BEK-200L: 0.2%, TT-615 : 1.5%, talcum powder: 10%, transparent iron oxide color paste: 20%, deionized water: 60.3%.

[0076] The preparation steps of Water Grace are as follows:

[0077] (1) According to the above mass fraction, first mix B-70 with deionized water to obtain mixture A, and then pre-mix 5040, byk028, tegowet270, propylene glycol, and AMP-95 to obtain mixture B. At 400-500rpm, mixture B Add slowly to mixture A;

[0078] (2) After the addition of mixture B, add talcum powder and disperse at 2000rpm for 20 minutes to obtain mixture C;

[0079] (3) Finally, add TT-615, BEK-200L and transparent iron oxide color paste to mixture C, and disperse at 1000rpm for 20 minutes to obtain Water Gris.

Embodiment 2

[0081] A kind of Water Grace comprises the following components according to mass percentage:

[0082] Alkali-swellable water-based resin emulsion (B-70): 10%, BYK028: 0.3%, propylene glycol 20%, AMP-95: 1%, tegowet270: 0.2%, BEK-200L: 0.2%, TT-615: 1.5%, Transparent iron oxide color paste: 20%, deionized water: 46.8%.

[0083] The preparation steps of Water Grace are as follows:

[0084] (1) According to the above mass fraction, first mix B-70 with deionized water to obtain mixture A, then pre-mix byk028, tegowet270, propylene glycol, and AMP-95 to obtain mixture B, and slowly add mixture B at 400-500rpm into mixture A;

[0085] (2) After the addition of mixture B, disperse at 2000rpm for 20 minutes to obtain mixture C;

[0086] (3) Finally, add TT-615, BEK-200L and transparent iron oxide color paste to mixture C, and disperse at 1000rpm for 20 minutes to obtain Water Gris.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com