Plant source extract anti-bacterial preservative film, and preparation method and application thereof

A plant-derived extract and fresh-keeping film technology, which is applied to the field of plant-derived extract antibacterial fresh-keeping film and its preparation, can solve the problems of low water vapor transmission rate, non-degradation, environmental pollution, etc., and achieves good moisture permeability, air permeability, cost Inexpensive, broad-spectrum antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation process of the Eupatoria adenophorum ethanol extract used in the present invention is as follows: the leaves of Eupatoria adenophorum are dried and pulverized at room temperature, and passed through 50 sieves to obtain Eupatoria adenophorum powder; put the Eupatoria adenophorum powder into an extraction kettle , adding an ethanol solution with a concentration of 95% by volume, soaking and extracting at 40°C for 3 times, each extraction for 24 hours, and filtering through 8 layers of gauze. The final filtrate was vacuum-concentrated with a rotary evaporator to a concentration of 60 mg / ml (60 mg of solid matter per 1 ml) to obtain a concentrated solution of Eupatorium adenophorum.

[0039] Concentration test: Accurately pipette 1ml of uniform extract in a vessel with a pipette gun, put it in a freeze dryer to remove solvent, concentrated concentration=(m 1 -m 2 ) / 1ml, where m 1 is the mass of vessel and solid, m 2 For the quality of the vessel.

Embodiment 1

[0041] (1) Preparation of PVA films containing different components:

[0042] A film: Add 10g of polyvinyl alcohol (PVA-088200) into 90g of deionized water, and let it stand for 12 hours to fully swell. Stir at a temperature of 80°C at a speed of 200 rpm for 1h, the polyvinyl alcohol is completely dissolved, and a polyvinyl alcohol solution I with a concentration of 10wt% is obtained; solution I is added with 0.5wt at 40°C under stirring (200rpm) % boric acid solution 3ml, after stirring for 0.5h, add 2ml of 4mol / L hydrochloric acid and 1g of glycerin, and continue to insulate and stir for 1h to obtain solution II; 2 Add 3mL of the solution into the solution II, heat and stir for 30 minutes, and disperse evenly to obtain the solution III. Pour an appropriate amount of the solution III on a clean flat glass, cast it into a film, and dry it under natural conditions to obtain the A film and store it in a desiccator. In, pending antibacterial test;

[0043]Film B: Add 10g of pol...

Embodiment 2

[0057] (1) Add 15g of polyvinyl alcohol (088-20) to 85g of deionized water and let it stand for 12 hours to fully swell. Stir at a temperature of 95°C at a speed of 200 rpm for 1h, the polyvinyl alcohol is completely dissolved, and a polyvinyl alcohol solution with a concentration of 15wt% is prepared, and 0.5wt% of polyvinyl alcohol is added at 45°C under stirring (200rpm). Boric acid solution 5ml, after stirring for 0.5h, add 2ml of 4mol / L hydrochloric acid and 1.2g of glycerin, continue to insulate and stir for 1h to obtain solution I;

[0058] (2) Take 10mg / ml nano TiO 2 Add 3 mL of the solution to the solution I prepared in step (1), and continue to stir at 45°C for 30 minutes until the solution is evenly dispersed to obtain solution II;

[0059] (3) Take 5 g of Eupatorium adenophorum ethanol extract of 60 mg / ml, add 0.5 g Tween 80, stir and emulsify at room temperature at a speed of 200 rpm to obtain solution III;

[0060] (4) After solution II is cooled to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

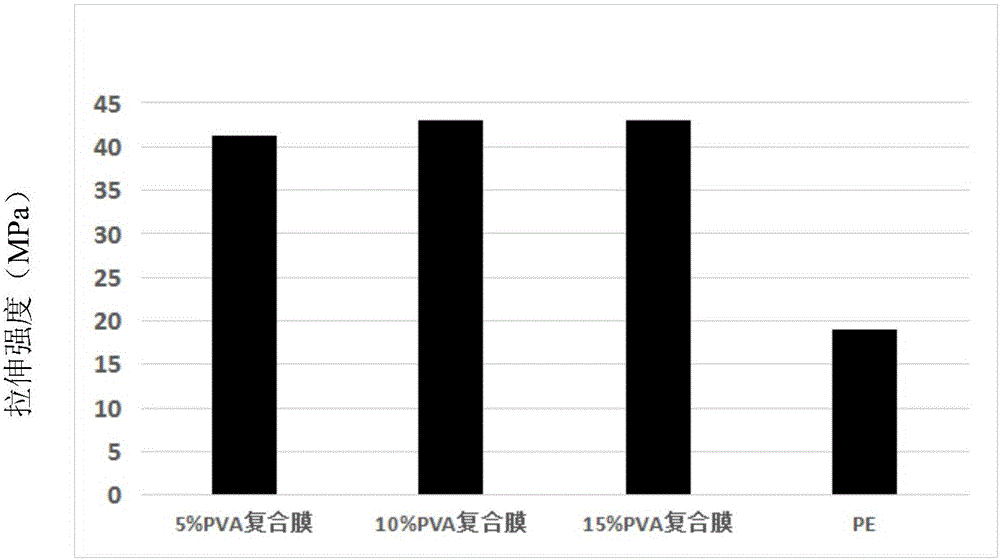

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com