Second component prepared on basis of polyurethane degradation products for polyurethane plastic runways, method for preparing second component and application thereof

A plastic runway and degradation product technology, applied in the fields of plastic runway and polyurethane plastic runway, can solve the problem of high cost and achieve the effect of low cost, high economic benefit and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

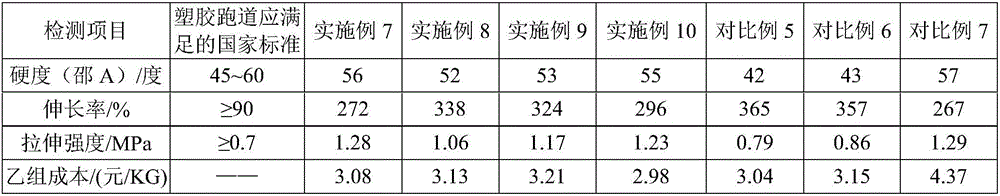

Examples

Embodiment 1

[0044] S1. Break 100 parts of polyurethane elastomer product leftovers into the reaction kettle together with 10 parts of ethylene glycol and 1 part of catalyst potassium acetate;

[0045] S2. Heating, controlling the reaction temperature to 180° C., the reaction time is 3 hours, and discharging to obtain a polyurethane degradation product.

Embodiment 2

[0047] S1. 100 parts of waste polyurethane elastomer products are broken, and 5 parts of ethylene glycol, 10 parts of propylene glycol, and 3 parts of catalyst ethylenediamine are added to the reactor;

[0048] S2. Heating, controlling the reaction temperature to 230° C., the reaction time is 1 hour, and discharging to obtain a polyurethane degradation product.

Embodiment 3

[0050] S1. Break 100 parts of polyurethane elastomer product leftovers into the reaction kettle together with 10 parts of diethylene glycol, 5 parts of butanediol, and 2 parts of catalyst ethanolamine;

[0051] S2. Heating, controlling the reaction temperature to 200° C., the reaction time is 2 hours, and discharging to obtain a polyurethane degradation product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com