Sand prevention multi-branched polymer for oil-water well and preparation method of sand prevention multi-branched polymer

A multi-branched, oil-water well technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of low sand-fixing strength and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

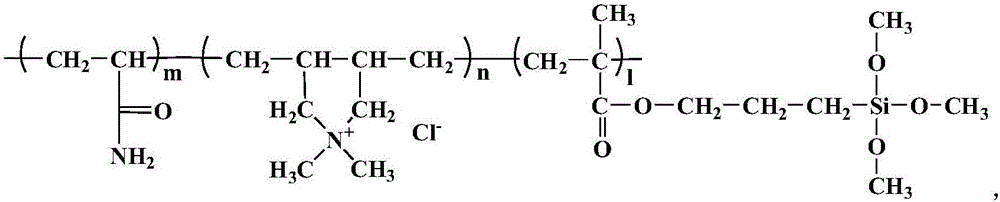

Embodiment 1

[0022] Example 1, acrylamide monomer was dissolved in water at 40°C to prepare acrylamide mother liquor with a concentration of 20%, and then dimethyl diallyl ammonium chloride, 3-(methacryloyloxy)propane Trimethoxysilane (KH570 / A174) and acrylamide mother liquor were mixed according to the mass ratio of 1:3:5, and the pH of the mixed solution was adjusted to 7.0. Nitrogen was passed through the mixed solution at a speed of 60mL / min to remove oxygen for 30min, and then ammonium persulfate / sodium bisulfite of 1% of the total monomer mass was added as an initiator, and placed in a water bath at 50°C for 1h to react, The colloidal product obtained, shredded, dried, pulverized to obtain the terpolymer of AM, DMDAAC and KH570 / A174, the molecular structure is:

[0023]

[0024] In the formula, m=14000-100000, n=6000-40000, l=6000-50000, and the molecular weight is 5-20 million.

Embodiment 2

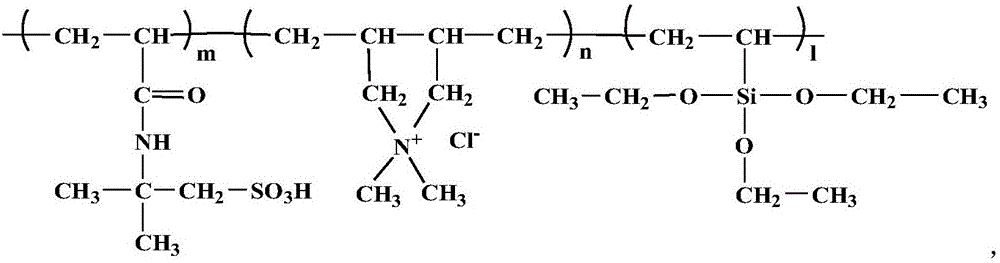

[0025] Example 2, 2-acrylamido-2-methylpropanesulfonic acid monomer was dissolved in water at 30°C to prepare a mother liquor with a concentration of 20%, and then dimethyl diallyl ammonium chloride, ethylene Triethoxysilane (A151) and 2-acrylamido-2-methylpropanesulfonic acid mother liquor were mixed according to the mass ratio of 1:1:5, and the pH of the mixed solution was adjusted to 6.5. Pass nitrogen gas to the mixed solution at a speed of 30mL / min to remove oxygen for 40min, then add potassium persulfate / sodium bisulfite with a total monomer mass of 0.5% as an initiator, and place it in a water bath at 60°C for 0.5h to react , the colloidal product that obtains, after cutting, drying, pulverizing obtains the terpolymer of AMPS, DMDAAC and A151, molecular structure is:

[0026]

[0027] In the formula, m=5000-30000, n=6000-40000, l=8000-60000, and the molecular weight is 5-20 million.

Embodiment 3

[0028] Example 3, acrylamide monomer was dissolved in water at 20°C to prepare a mother liquor with a concentration of 20%, and then dimethyl diallyl ammonium chloride, vinyltrimethoxysilane (A171) and acrylamide The mother liquor is mixed according to the mass ratio of 1:2:5, and the pH of the mixed solution is adjusted to 7.5. Pass nitrogen gas through the mixed solution at a rate of 10mL / min to remove oxygen for 15min, then add tert-butyl hydroperoxide / sodium metabisulfite with a total monomer mass of 0.1% as an initiator, and place it in a water bath at 30°C for 2h to react , the obtained colloidal product was shredded, dried and pulverized to obtain a terpolymer of AM, DMDAAC and A171. The molecular structure is:

[0029]

[0030] In the formula, m=14000-100000, n=6000-40000, l=10000-80000, and the molecular weight is 5-20 million.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com