Processing tools and inserts for processing tools

A technology for machining tools and inserts, applied in the field of inserts, can solve the problem of not finding the specification of insert size, and achieve the effect of improving surface quality, small cutting power, less friction and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

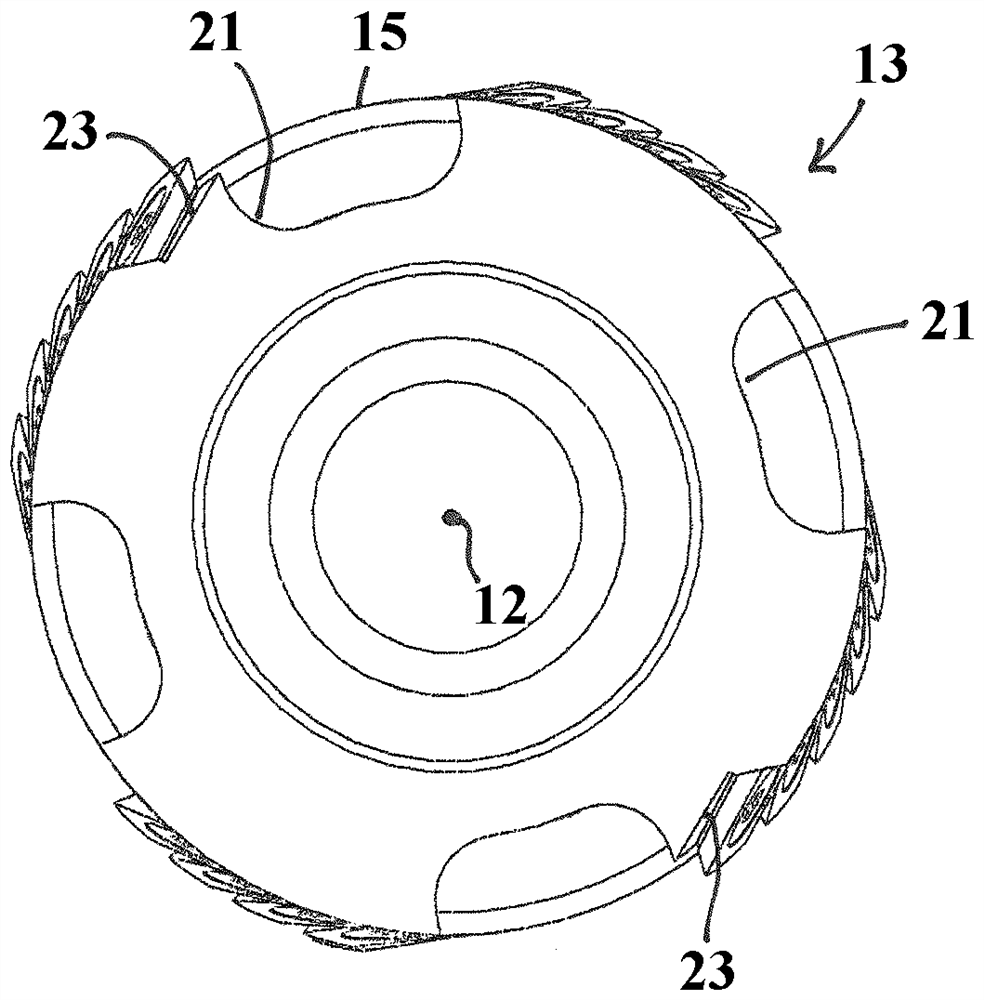

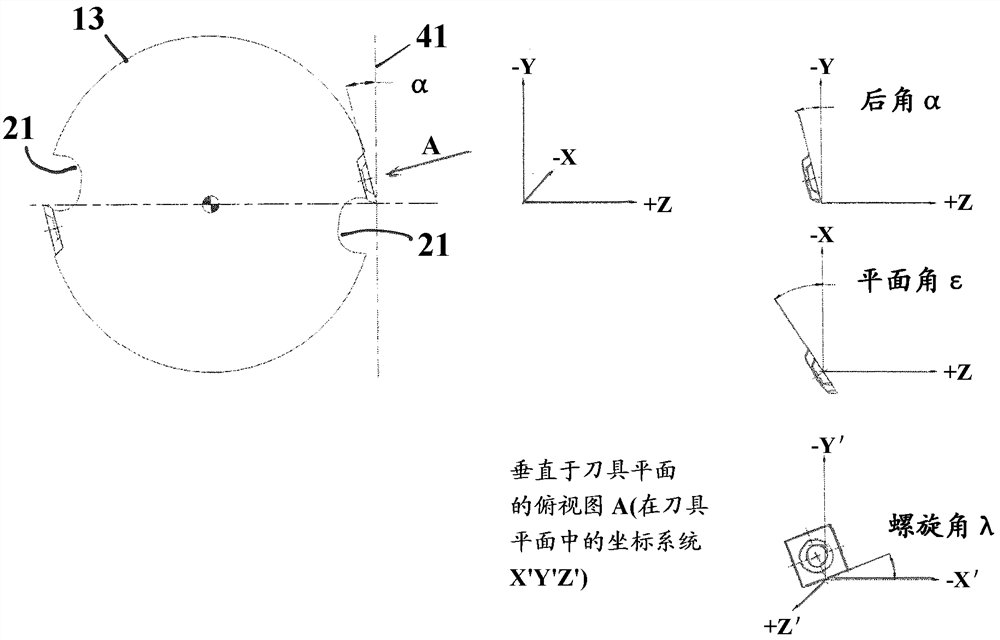

[0057] figure 1 and 2 In a perspective view, an embodiment of the invention for the treatment of materials (in particular for wood or wood-based materials such as coated or uncoated Spanplatte, hardboard or the like) A first embodiment of a machining tool 11 for cutting. However, the processing tool 11 can also be suitable for other materials such as fiber composite plastic or the like. The machining tool 11 is designed as a helical milling cutter and is provided for mounting on a tool shank (not shown). Drive processing tool 11 to rotate around axis of rotation 12 in operation ( figure 1 ).

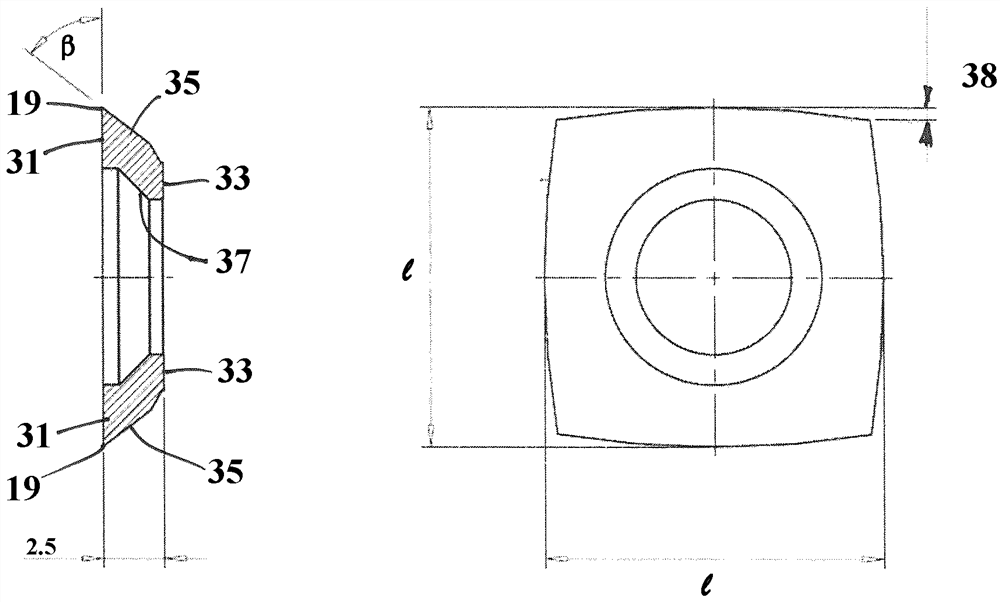

[0058] The base body 13 of the machining tool 11 is substantially cylindrical, wherein on its cylindrical peripheral surface 15 a plurality of inserts 17 in the form of peripheral knives with cutting edges 19 are arranged. The blades 17 are arranged in at least one row, preferably at least two or more rows arranged in the peripheral direction, wherein the rows or groups overlap each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com