Cleaning machine for gas spring pressure pipe

A pressure tube and cleaning machine technology, applied in the field of gas spring manufacturing, can solve the problems of poor cleaning quality of pressure tubes, achieve the effects of increasing cleaning effect, high cleaning efficiency, and increasing pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

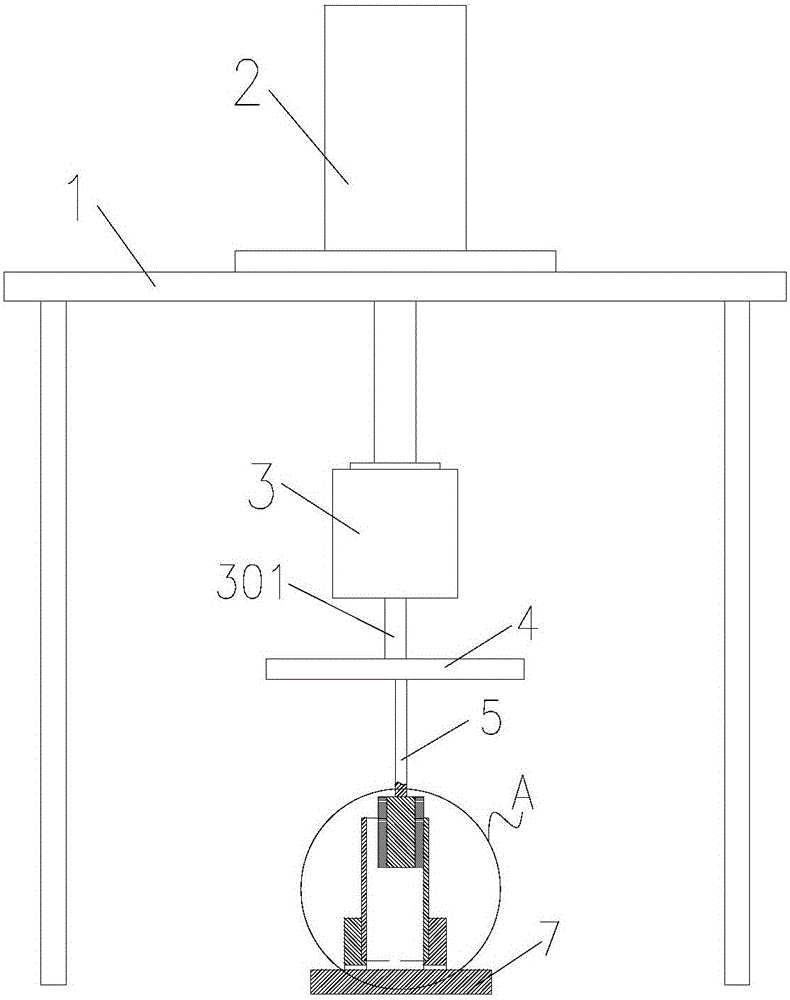

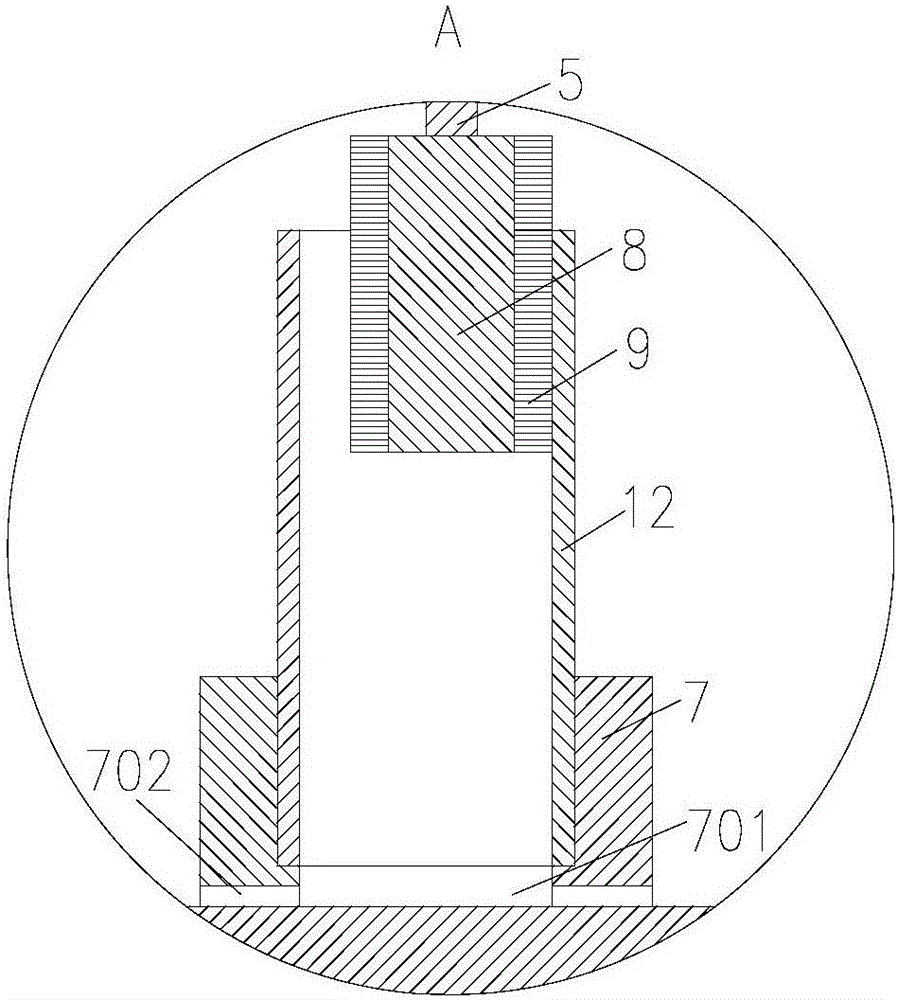

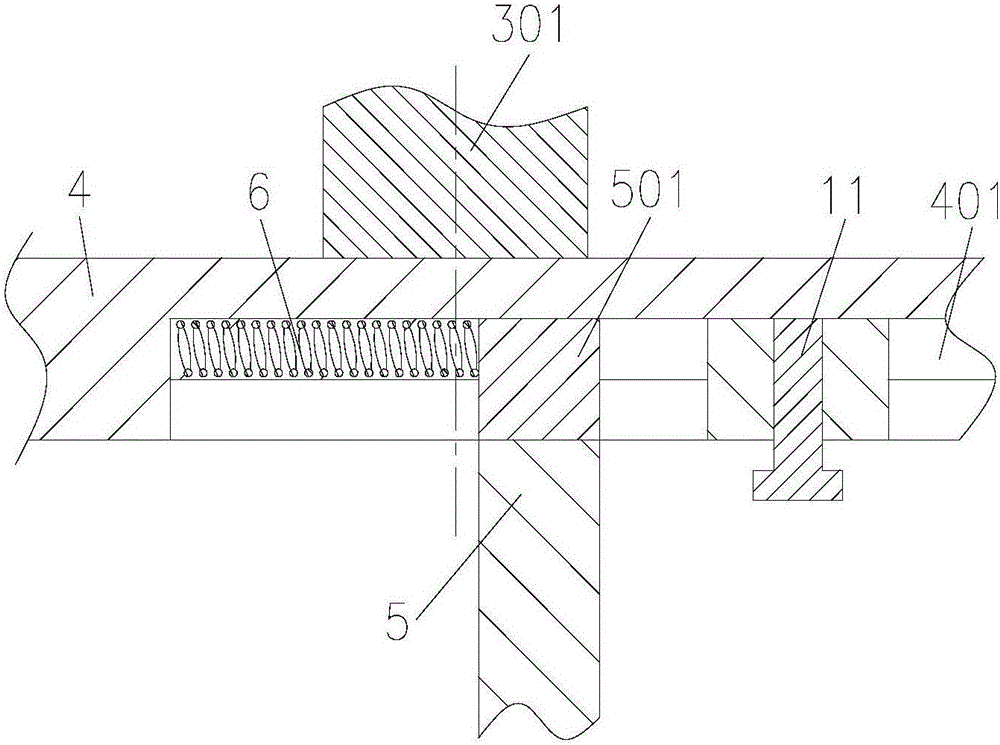

[0017] Such as Figure 1-3 As shown, a cleaning machine for a gas spring pressure tube includes a frame 1 and a hydraulic cylinder 2 arranged on the frame 1 with an extended end facing downward, and a motor 3 is arranged on the extended end of the hydraulic cylinder 2 A turntable 4 is fixedly connected to the main shaft 301 of the motor 3, the turntable 4 is provided with a rotating shaft 5, the upper end of the rotating shaft 5 is provided with a T-shaped protrusion 501, and the lower end of the rotating shaft 5 is provided with a brush assembly, so The lower surface of the turntable 4 is provided with a T-shaped groove 401 that matches the T-shaped protrusion 501, the T-shaped protrusion 501 is slidably arranged in the T-shaped groove 401, and the T-shaped groove 401 is connected to the T-shaped groove 401. A spring 6 is arranged between the T-shaped protrusions 501, and a fixing seat 7 is arranged below the brush assembly. The fixing seat 7 is provided with a positioning hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com