In-situ regeneration method of ammonium sulfate poisoning denitration catalyst

A denitration catalyst, in-situ regeneration technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve problems such as limited application, poisoning and deactivation of ammonium sulfate, and achieve short regeneration time. , The effect of low regeneration cost and saving regeneration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In the SCR main reactor, the fresh catalyst is at normal pressure, the temperature is 200°C, SO 2 The concentration is 2000mg / m 3 , NO concentration is 800mg / m 3 , the ammonia nitrogen ratio is 1.0, and the space velocity is 5000h -1 The denitrification efficiency of the catalyst dropped from 90.5% to 50% after running for 1000 hours under the flue gas condition.

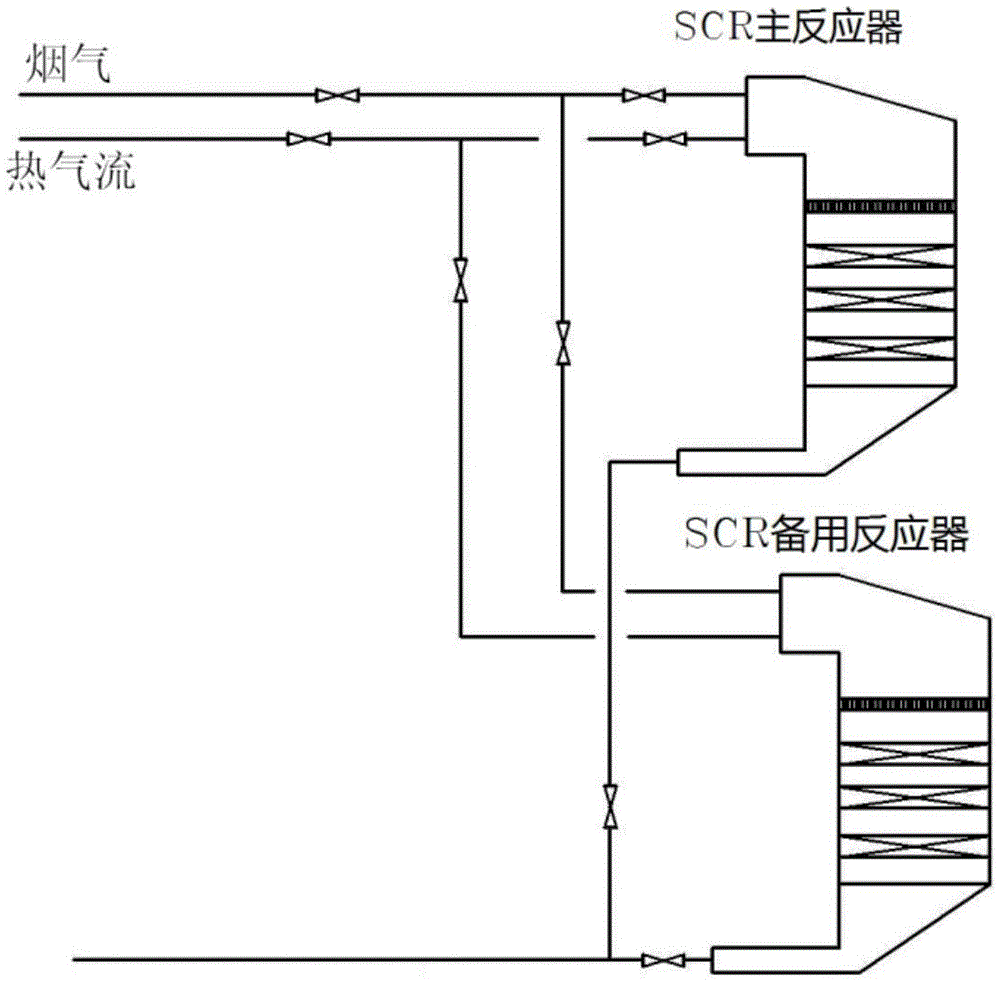

[0031] Process flow of the present invention such as figure 1 As shown, when the concentration of nitrogen oxides in the flue gas is close to the emission limit, the flue gas is switched to the SCR standby reactor, and the hot air is passed into the SCR main reactor, wherein the space velocity of the air is 1000h -1 , the temperature is 350° C.; after the hot air is purged for 4 hours, the feeding is stopped, and the regeneration of the denitration catalyst of the present invention is completed.

[0032] The flue gas was switched back to the SCR main reactor, and the concentration of nitrogen oxides at th...

Embodiment 2

[0034] In the SCR main reactor, the fresh catalyst is at normal pressure, the temperature is 200°C, SO 2 The concentration is 2000mg / m 3 , NO concentration is 800mg / m 3 , the ammonia nitrogen ratio is 1.0, and the space velocity is 5000h -1 The denitrification efficiency of the catalyst dropped from 90.5% to 50% after running for 1000 hours under the flue gas condition.

[0035] Process flow of the present invention such as figure 1 As shown, when the concentration of nitrogen oxides in the flue gas is close to the emission limit, the flue gas is switched to the SCR standby reactor, and the hot air is passed into the SCR main reactor, wherein the space velocity of the air is 2000h -1 , the temperature is 400° C.; after the hot air is purged for 2.0 hours, the feeding is stopped, and the regeneration of the denitration catalyst of the present invention is completed.

[0036] The flue gas was switched back to the SCR main reactor, and the concentration of nitrogen oxides at ...

Embodiment 3

[0038] In the SCR main reactor, the fresh catalyst is at normal pressure, the temperature is 200°C, SO 2 The concentration is 2000mg / m 3 , NO concentration is 800mg / m 3 , the ammonia nitrogen ratio is 1.0, and the space velocity is 5000h -1 The denitrification efficiency of the catalyst dropped from 90.5% to 50% after running for 1000 hours under the flue gas condition.

[0039] Process flow of the present invention such as figure 1 As shown, when the concentration of nitrogen oxides in the flue gas is close to the emission limit, the flue gas is switched to the SCR standby reactor, and the hot nitrogen is passed into the SCR main reactor, wherein the space velocity of nitrogen is 1000h -1 , the temperature is 350° C.; after the hot nitrogen is purged for 4.0 h, the feeding is stopped, and the regeneration of the denitration catalyst of the present invention is completed.

[0040] The flue gas is switched back to the SCR main reactor, and the concentration of nitrogen oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com