Liquid film dedusting device and desulfurizer dedusting rectification system with same

A technology of dust removal device and desulfurization tower, which is applied in combination device, use of liquid separation agent, dispersed particle separation, etc., can solve the problems affecting the living environment and entrainment of residents around the power plant, reduce the risk of blockage, avoid secondary pollution, The effect of reducing the amount of entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

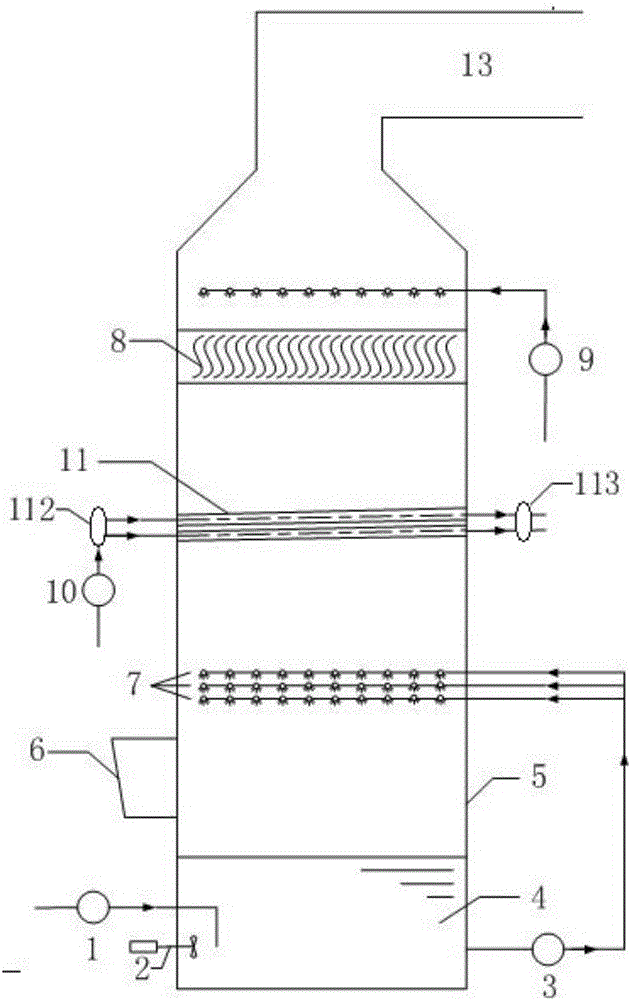

[0027] see Figure 1-2 As shown, a desulfurization tower dedusting rectification system of a preferred embodiment of the present invention includes a desulfurization tower 5 and a liquid film dedusting device. Header 112, return water header 113, circulating water pump 10 and circulating waterway 12, circulating water pump 10 and circulating waterway 12 are located outside the desulfurization tower 5, the distance between two adjacent layers of dust removal units 11 is 80 mm, and each layer of dust removal units 11 includes several The circular tubes 111 arranged side by side and the distance between the circular tubes 111 is 100mm, the circular tubes 111 of the two adjacent layers of dust removal units 11 are arranged in parallel and staggered to form a tubular dust removal assembly, the water inlet of each circular tube 111 is connected to the water inlet The headers 112 are connected, the water outlet of each round pipe 111 is connected with the return water header 113, and...

Embodiment 2

[0040] Such as Figure 3-4 As shown, the desulfurization tower dedusting rectification system of a preferred embodiment of the present invention comprises a desulfurization tower 5 and a liquid film dedusting device, and the liquid film dedusting device comprises a dedusting assembly consisting of two layers of dedusting units (11), a water inlet coupling Tank 112, return water header 113, circulating water pump 10 and circulating waterway 12, the distance between two adjacent layers of dust removal units 11 is 3m, and each layer of dust removal units 11 includes several baffles 111 arranged in parallel and adjacent baffles The distance between 111 is 30 mm. Preferably, the baffles 111 are existing baffles transformed into hollow baffles, and the baffles 111 of the adjacent two layers of dust removal units 11 are arranged in parallel and staggered to carry out flue gas. Rectification, forming a baffle type dust removal assembly and a roof-like arrangement, the inclination angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com