Multi-channel floor drain

A multi-channel, floor drain technology, applied in the field of sanitary ware, can solve the problems of slow drainage speed, small water output, failure, etc., and achieve the effect of reducing the possibility and smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

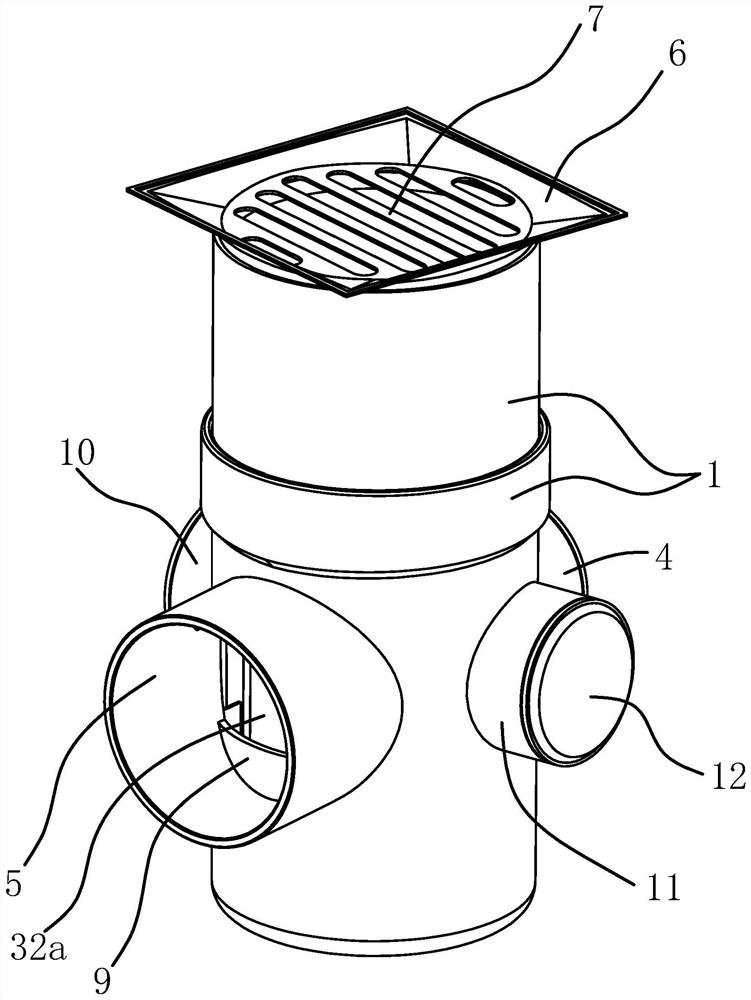

[0032] Such as Figure 1 to Figure 4As shown, the multi-channel floor drain includes a main pipe body 1 having a cavity 2, a diversion cover 6 and a floor drain cover 7 are provided on the top of the main pipe body 1, and a slot leading to the inside of the cavity 2 is provided on the floor drain cover 7, and the main pipe The bottom end of the body 1 is closed with a bottom plate 1a. The multi-channel floor drain is installed on the wading ground in the house, and the water flows into the cavity 2 from the floor drain cover 7 on the top of the main body 1. On the outer peripheral wall of the main body 1, there is also an outlet pipe 5 communicating with the cavity 2, and the water flows into the cavity 2. The water in the cavity 2 is discharged into the sewer from the outlet pipe 5. Since the outlet pipe 5 is located on the outer peripheral wall of the main body 1, the inner diameter of the outlet pipe 5 can be the same size as the inner diameter of the main body 1 to increas...

Embodiment 2

[0042] This embodiment is roughly the same as Embodiment 1, the difference is that three sets of limit assemblies 8 are provided on the inner wall of the main pipe body 1 to limit the rotation of the partition plate 3a in the main pipe body 1, and two sets of limit assemblies 8 are respectively located in the water outlet pipe. 5 on both sides, the limiting component 8 includes a limiting rib 1 8a and a limiting rib 2 8b arranged vertically. The third group of limiting components 8 is located above the water outlet pipe 5 , and the lower surface of the deflector 3 b is provided with inserting ribs inserted on the third group of limiting components 8 .

Embodiment 3

[0044] In this embodiment, it is roughly the same as the first embodiment, the difference is that both the partition plate 3 a and the deflector 3 b are integrally formed with the main pipe body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com