Method for producing histones by utilizing soybean protein concentrate

A technology of concentrated soybean protein and production organization, applied in the direction of textured treatment, plant protein processing, application, etc., can solve the problems of high cost, poor product quality, low finish, etc., and achieve improved production efficiency, good product quality, protein The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

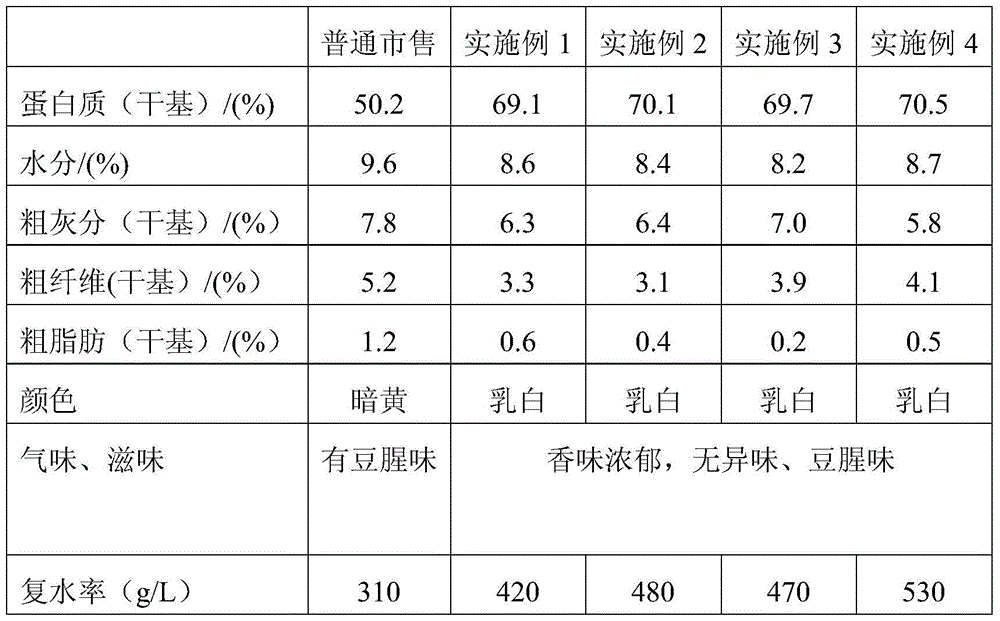

Examples

Embodiment 1

[0024] The described method of utilizing soybean protein concentrate to produce tissue protein comprises the following steps:

[0025] (1) crushing and sieving: use the soybean protein concentrate extracted by alcohol method as raw material, pass through an 80-mesh sieve after crushing;

[0026] (2) Quenching and tempering: the pulverized material is uniformly mixed in the mixing tank and transported to the conditioner, and at the same time, water is added and steam is passed to make the moisture content of the material 40%, and the tempering temperature is controlled to be 60° C. for 3 minutes;

[0027] (3) Extrusion and puffing: extrude and puff the conditioned material with a twin-rod extrusion puffing machine, and control the temperatures in the five zones of the twin-rod extrusion puffing machine to 60°C, 75°C, 90°C, and 130°C , 100°C, so that the material can be preheated, reacted and formed in the extruder;

[0028] (4) cutting: control the cutter speed to be 200r / min,...

Embodiment 2

[0031] The described method of utilizing soybean protein concentrate to produce tissue protein comprises the following steps:

[0032] (1) Crushing and sieving: using the concentrated soybean protein extracted by alcohol method as the main ingredient, mixing and pulverizing the main ingredient and auxiliary materials and passing through a 100-mesh sieve, wherein the auxiliary materials account for 30% of the total material quality;

[0033] (2) Tempering: the pulverized material is uniformly mixed in the mixing tank and then transported to the conditioner, and at the same time, water is added and steam is passed to make the moisture content of the material 85%, and the tempering temperature is controlled to be 100°C for 8 minutes;

[0034] (3) Extrusion and puffing: Extrude and puff the tempered material with a twin-rod extrusion puffing machine, and control the temperatures in the five zones of the twin-rod extrusion puffing machine to be 80°C, 90°C, 100°C, and 160°C. , 130°C...

Embodiment 3

[0038] The described method of utilizing soybean protein concentrate to produce tissue protein comprises the following steps:

[0039] (1) crushing and sieving: the soybean protein concentrate extracted by the alcohol method is used as the main ingredient, and the main ingredient and the auxiliary materials are mixed and crushed and passed through a 90-mesh sieve, wherein the auxiliary materials account for 20% of the total material quality;

[0040] (2) Quenching and tempering: the pulverized material is mixed evenly in the mixing tank and transported to the conditioner, and at the same time, water is added and steam is passed to make the moisture content of the material 69%.

[0041] (3) Extrusion and puffing: Extrude and puff the tempered material with a twin-rod extrusion puffing machine, and control the temperatures in the five zones of the twin-rod extrusion puffing machine to 70°C, 80°C, 95°C, and 140°C , 110°C, so that the material can be preheated, reacted and formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com