Vertical automatic edible mushroom flow-line production system

A production system, edible mushroom technology, applied in application, horticulture, botanical equipment and methods, etc., can solve the problems of low production efficiency, waste of production space, etc., to improve production efficiency, optimize quality, and save transportation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

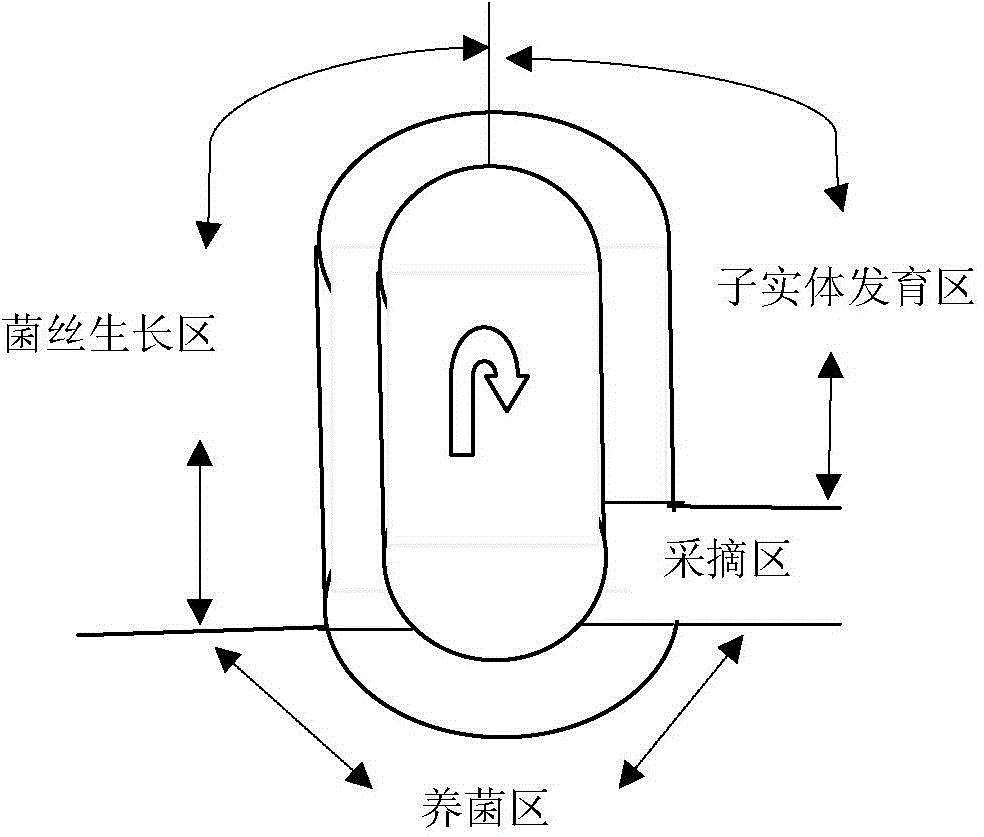

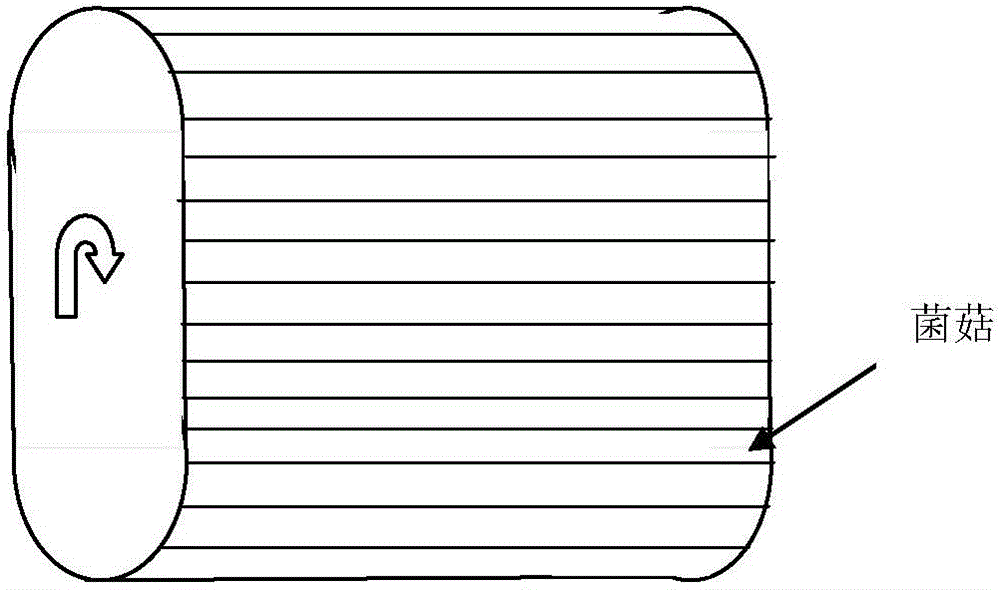

[0052] The assembly line production system of the present invention adopts vertical arrangement, and the assembly line production line is arranged in an elliptic shape around the rotation axis to form an elliptical assembly line production line, and the assembly line production line rotates in an ellipse around the rotation axis. According to the four production steps of edible mycelium growth, fruit body development, picking and bacteria cultivation, the entire flow-type production line is divided into mycelium growth area, fruit body development area, picking area and bacteria cultivation area. The proportion of each area on the production line is The length is determined according to the time required by different mushrooms in different production stages. Wherein, an airtight cover is set outside the mycelium growth area, the fruit body d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com