Device for non-slag production of iron, aluminum and titanium by utilizing reduction molten-salt growth method

A molten salt method and molten salt reaction technology are applied in the slag-free production device of aluminum and titanium reduction molten salt method, and in the field of iron, which can solve the problems of low production capacity, environmental pollution by waste residue, waste of resources, etc., and achieve low production cost and change. The effect of high pollution and lower investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing embodiment, the present invention will be further described:

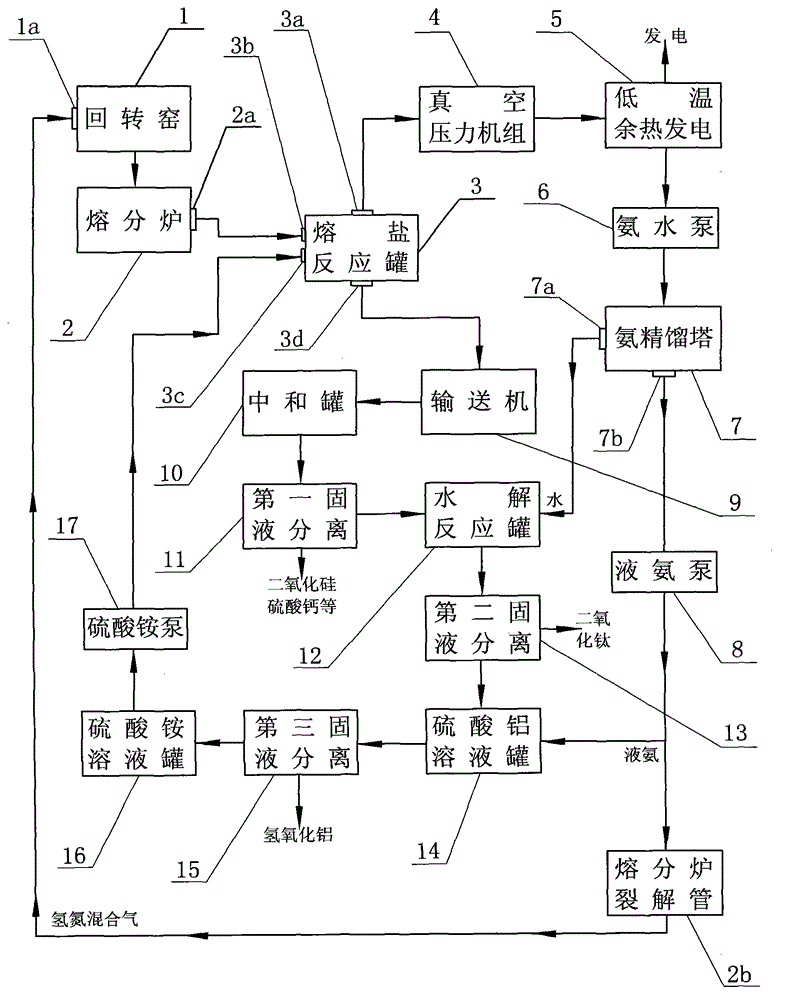

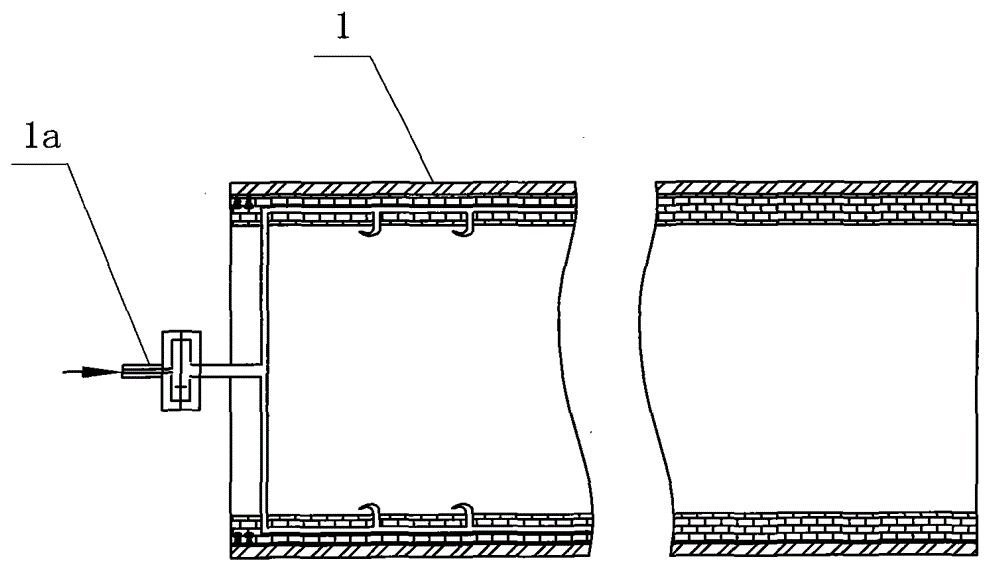

[0028] Such as figure 1 , 2 As shown, the slag-free production device of iron, aluminum and titanium reduction molten salt method includes rotary kiln 1, melting furnace 2, molten salt reaction tank 3, vacuum pressure unit 4 and low-temperature waste heat power generation 5, and the head of rotary kiln 1 passes through The closed channel is connected to the tail of the melting furnace 2; the head of the rotary kiln 1 is provided with a rotary kiln gas distribution plate 1a; the head of the melting furnace 2 is provided with a high-temperature molten slag outlet 2a, and the top of the melting furnace 2 is provided with a melting furnace cracking pipe 2b; The top of the molten salt reaction tank 3 is provided with an ammonia gas outlet 3a, the upper part is provided with a high-temperature molten slag inlet 3b, four liquid inlets 3c are arranged symmetrically at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com