A kind of solid polymer electrolyte and preparation method thereof

A solid polymer and electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolyte immobilization/gelation, etc., can solve the problems of low conductivity of solid polymer electrolytes, and achieve superior conductivity and internal The effect of low resistance and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

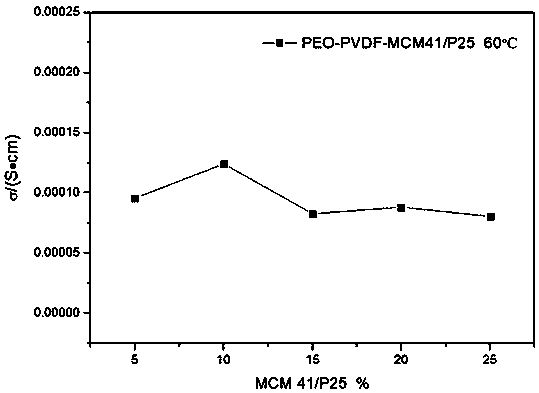

[0038] Take PEO and PVDF at a mass ratio of 1:1, weigh 1g and dissolve in N,N-dimethylformamide, then weigh 0.10g of lithium perchlorate (LiClO4) and dissolve in this mixed solution, and perform ultrasonication for 20min , make five groups, and then add 0.1g, 0.2g, 0.3g, 0.4g, 0.5g of modified mesoporous silica (MCM41 / P25) respectively, and stir in a water bath at 35°C for 24h.

[0039] The obtained viscous solution was poured on a smooth glass plate, scraped with a spatula, left at room temperature for 2h, and then moved into a vacuum oven at 60°C for 12h. A solid polymer electrolyte is obtained.

[0040] Use a scraper to peel off the solid polymer electrolyte membrane from the glass plate, cut it into an appropriate size, quickly move it into the glove box, and install it into a CR2032 button battery. The EIS test was carried out with an electrochemical workstation and the conductivity was obtained through calculation.

Embodiment 2

[0042] Take PEO and PVDF at a mass ratio of 1:1, weigh 1g and dissolve in N,N-dimethylformamide, then weigh 0.10g of lithium perchlorate (LiClO4) and dissolve in this mixed solution, and perform ultrasonication for 20min , and then add 0.2 g of modified mesoporous silica (MCM41 / P25), and stir in a water bath at 35° C. for 24 h.

[0043] The obtained viscous solution was poured on a smooth glass plate, scraped with a spatula, left at room temperature for 2h, and then moved into a vacuum oven at 60°C for 12h. A solid polymer electrolyte is obtained.

[0044] Use a scraper to peel off the solid polymer electrolyte membrane from the glass plate, cut it into an appropriate size, quickly move it into the glove box, and install it into a CR2032 button battery. EIS tests were performed with an electrochemical workstation.

Embodiment 3

[0046] Take PEO and PVDF at a mass ratio of 1:1, weigh 1g and dissolve them in N,N-dimethylformamide, then weigh 0.05g of lithium tetrafluoroborate and dissolve them in the mixed solution, perform ultrasonication for 20min, and then Add 0.2 g of modified mesoporous silica (MCM41 / P25), and stir in a water bath at 35° C. for 24 h.

[0047] The obtained viscous solution was poured on a smooth glass plate, scraped with a spatula, left at room temperature for 2h, and then moved into a vacuum oven at 60°C for 12h. A solid polymer electrolyte is obtained.

[0048] Use a scraper to peel off the solid polymer electrolyte membrane from the glass plate, cut it into an appropriate size, quickly move it into the glove box, and install it into a CR2032 button battery. EIS tests were performed with an electrochemical workstation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com