Machine vision-based tire tread detection method

A detection method and machine vision technology, applied in the direction of instruments, measuring devices, image data processing, etc., can solve the problems of large measurement errors, low efficiency, and insufficient detection methods, and achieve the effect of high precision and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

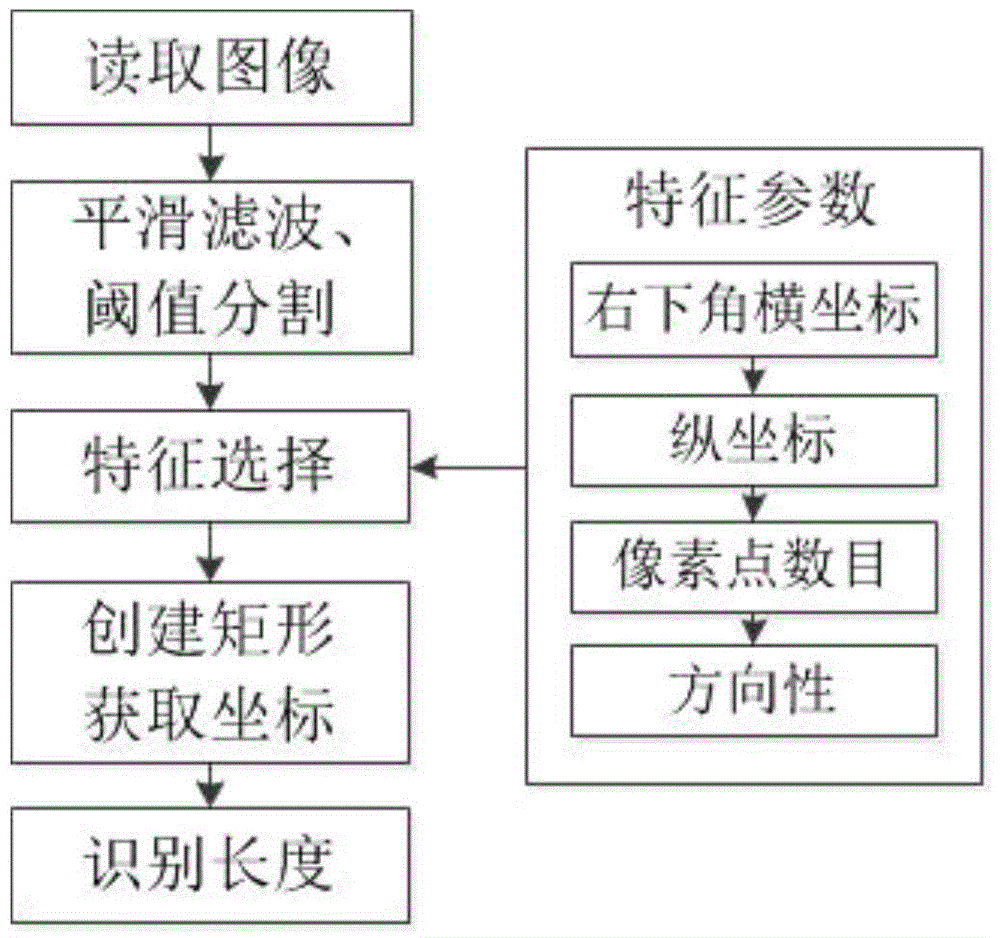

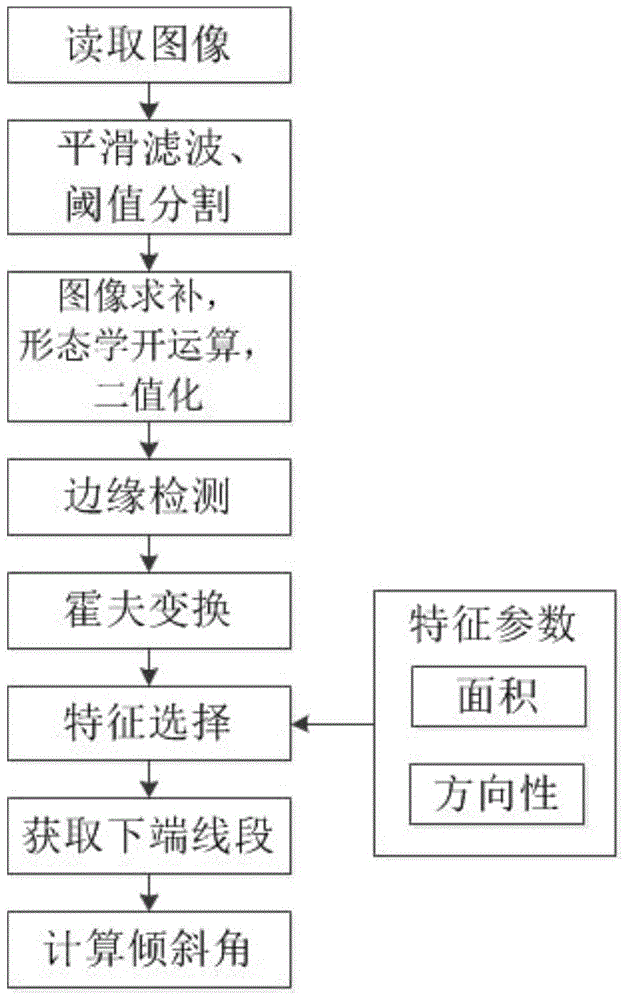

[0042] Such as figure 1 and 2 As shown, a tread detection method based on machine vision, the specific steps are as follows:

[0043] Step 1: Collect tread images with industrial cameras.

[0044] Step 2: Perform smoothing and filtering on the tread image. Here, considering that the Gaussian filter and its reciprocal cannot be realized in a recursive manner, the Deriche recursive smoothing filter is selected for smoothing and filtering.

[0045] Step 3: Perform threshold segmentation on the image after smoothing and filtering according to a preset threshold, and the preset threshold is automatically set by an automatic threshold segmentation operator according to the image after smoothing and filtering.

[0046] Step 4: Calculate the average value and variance of the gray histogram of the image processed in step 3, and extract the preprocessed image according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com