Traceability method of power module

A power module and traceability technology, applied in the field of power electronics, can solve problems such as manual selection, inability to trace power modules, errors, etc., and achieve the effect of simple method, avoiding program selection errors and step omission errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

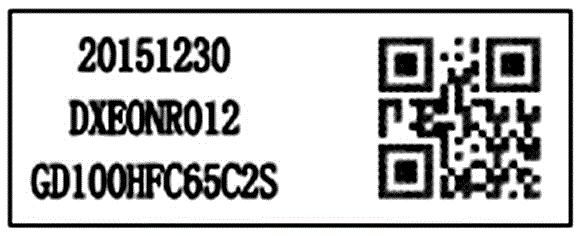

[0025] Example: figure 1 As shown, print a QR code with information such as the product model, batch number, and list number of the batch on the production work order. The engineer needs to set up the QR code information and all the programs and methods that need to be called in the production process. At the DBC, substrate and shell marking sites, call the corresponding marking program through the QR code information, and input the batch information. Into the DBC, substrate and shell marking information, and each DBC, substrate and shell has a unique number. In each production process and site that needs to call programs and methods, scan the QR code on the work order to call the corresponding program for production and testing. If the work order information does not match the substrate and DBC configuration information, the device will alarm to prevent products from entering the site.

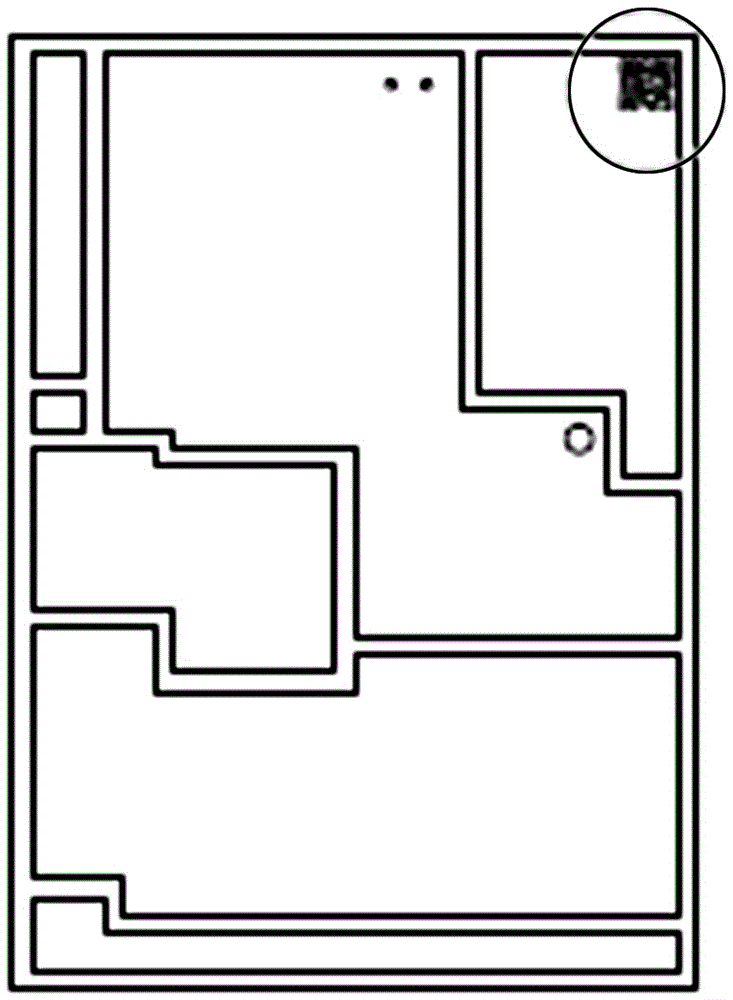

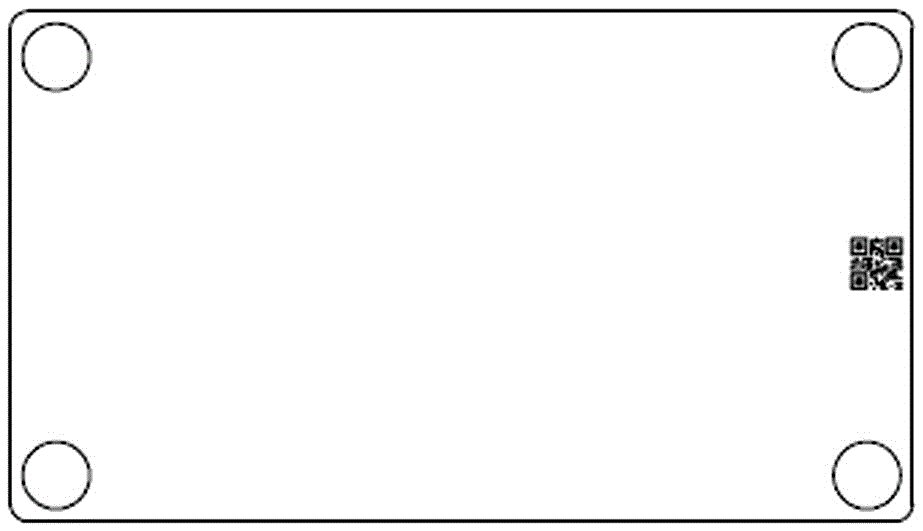

[0026] figure 2As shown, the two-dimensional code is marked on the DBC, and the marki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com