A method to determine the pre -exhausting gas bandwidth of the coal mining of the coal mine

A technology for mining working face and gas strip, applied in measuring devices, instruments, scientific instruments, etc., can solve the problem of large error in the predicted value of gas emission, and achieve the effects of low cost, easy capture and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

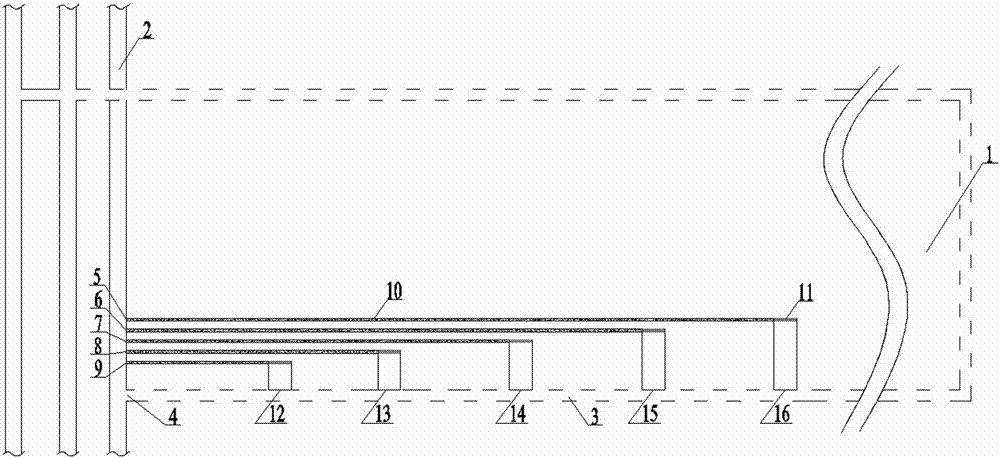

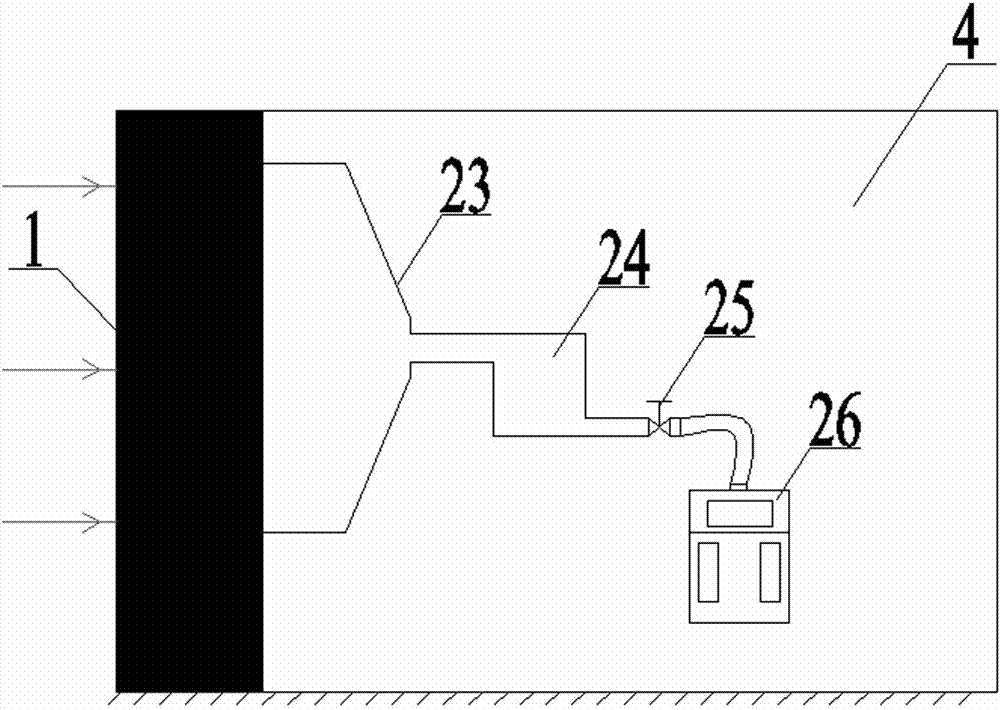

[0025] A method for measuring the width of the pre-drainage gas belt in a roadway of a coal mine mining face, comprising the following steps:

[0026] 1. Calibrate the gas injection drilling position

[0027] Select the roadway 2 in the mining area closest to the planned mining face 1 as the construction site for gas injection drilling, mark the entrance 4 of the planned working face along the groove, start from the entrance 4 of the planned working face along the groove 3, and follow the direction of the roadway in the coal mining area Mark the first gas injection borehole 9 at a distance of 10m, and then calibrate a gas injection borehole every 1m, that is, the second gas injection borehole 8, the third gas injection borehole 7, the fourth gas injection borehole 6, the Five gas injection drilling holes 5, a total of 5 gas injection drilling holes.

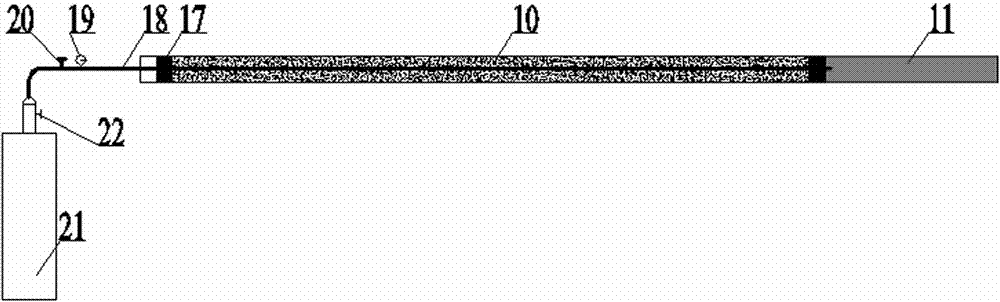

[0028] 2. Drilling, cementing and sealing in the hole:

[0029] Ordinary drilling rigs are used to construct gas injection dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com