Pedal rigidity comprehensive performance testing equipment

A technology of comprehensive performance and test equipment, which is applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of fixed, unsatisfactory, and adjustment test methods, and achieve flexible test methods and follow-up measurement accuracy High, good test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

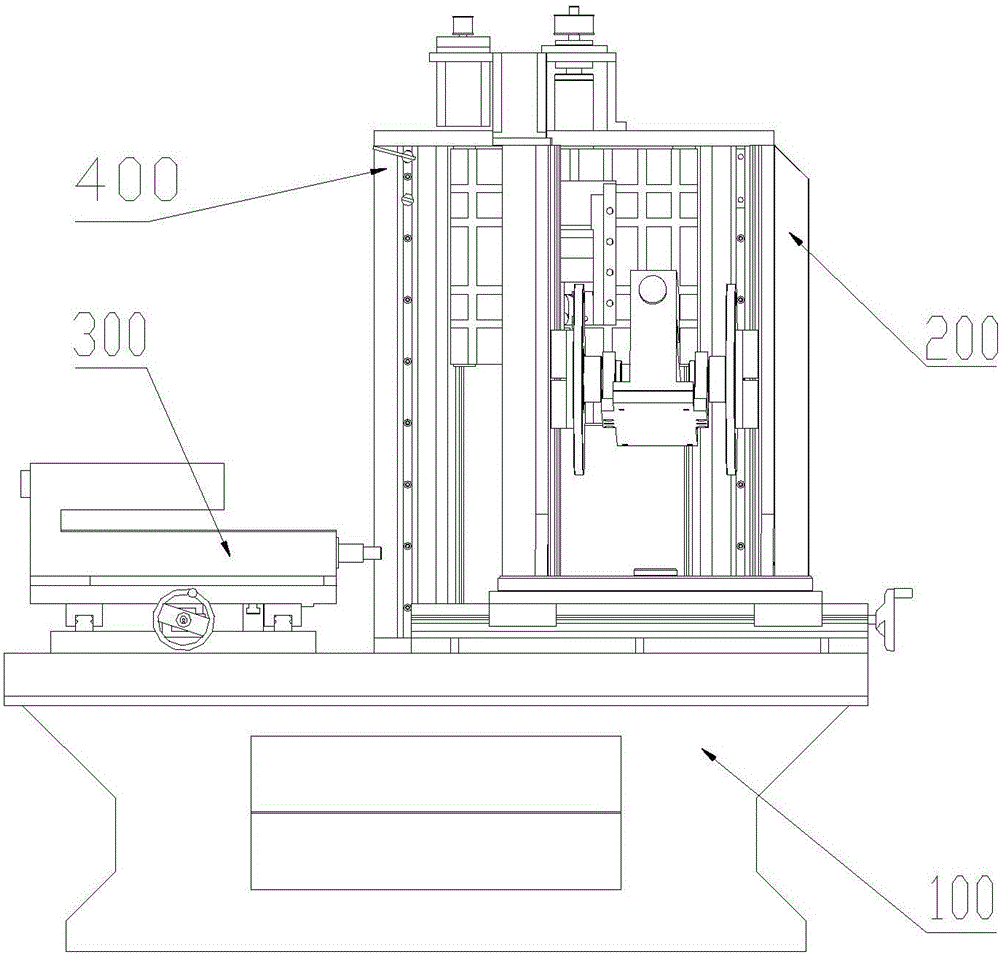

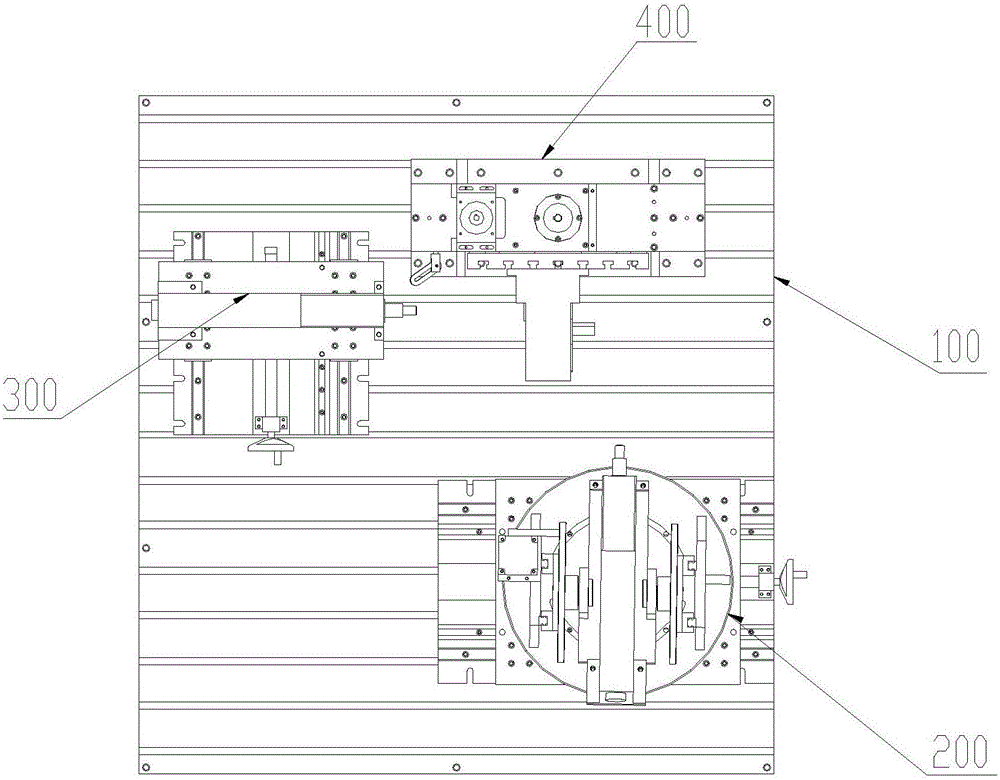

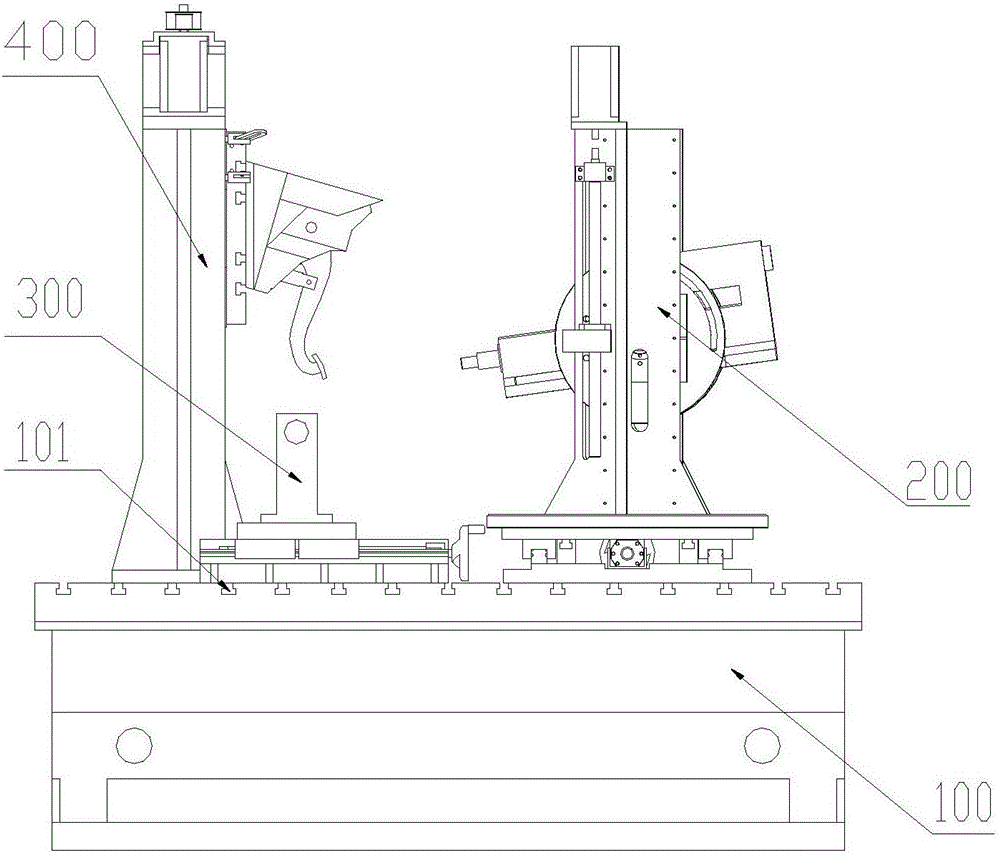

[0036] see Figure 1 to Figure 3 , is a preferred embodiment of pedal stiffness comprehensive performance test equipment, including a base 100, and a longitudinal loading mechanism 200, a lateral loading mechanism 300, and a test sample installation mechanism 400 installed on the base, and the test sample installation The mechanism 400 is used to install the test sample 500 , the longitudinal loading mechanism 200 is used to apply a longitudinal load to the test sample 500 , and the lateral loading mechanism 300 is used to apply a lateral load to the test sample 500 .

[0037] see Figure 1 to Figure 3 , the base 100 is a T-shaped slot platform, and the upper end surface of the base 100 is provided with a T-shaped slot 101, and the longitudinal loading mechanism 200, the lateral loading mechanism 300, and the test sample mounting mechanism 400 pass through the T-shaped slider respectively. Cooperate with the T-shaped groove 101 of the base, so that the horizontal and vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com