A device for measuring air flow in a pipeline

A technology of airflow flow and measuring device, which is applied in the field of flow rate and flow measurement of pulverized coal gas-solid two-phase fluid or single-phase high-temperature fluid flow rate and flow measurement, and can solve the problem that the actual flow rate and flow rate of the fluid cannot be truly reflected, and the measurement is difficult to take care of accurately The flow rate and coefficient of different temperature ranges are very different, so as to achieve the effect of improving safety and economy, reducing maintenance and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

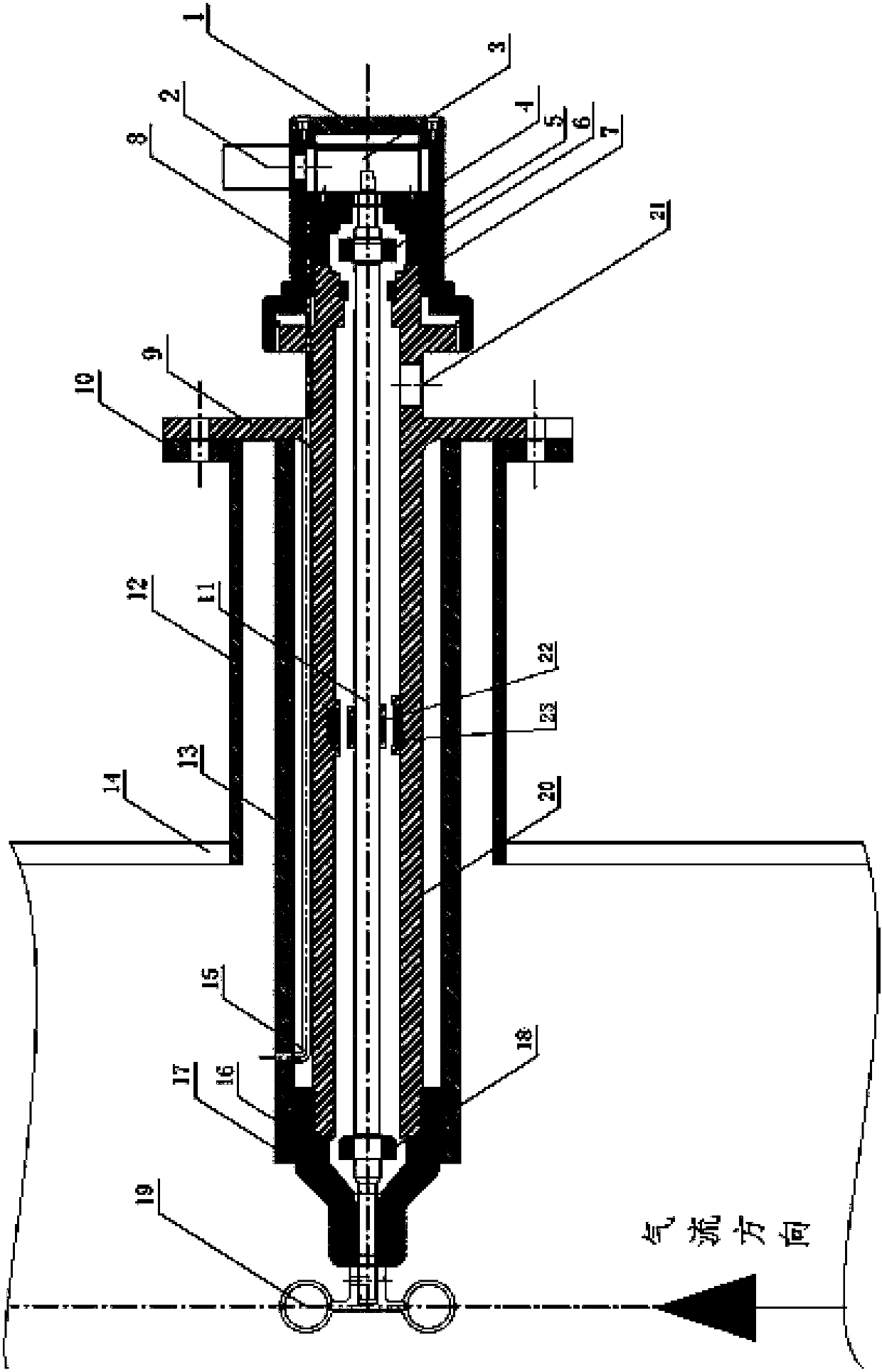

[0028] Below in conjunction with accompanying drawing and embodiment, the present invention is further described: as shown in Figure 1 pipeline air flow measuring device, comprises fan blade rotor 19, rotating shaft 11, measuring wind connecting pipe 20, rotational speed sensor 3, measuring wind pipe base 12 and data processor 2.

[0029] Among them, the speed sensor 3 is an encoder, which can convert the rotation angle into a pulse output. According to the accuracy of different types of encoders, it can output 360 to 2400 pulses per week. The data processor 2 can use PLC, single-chip or DSP to encode The output signal of the device can be directly connected to the data processor or DCS control system.

[0030] Fan blade rotor 19 is provided with three semicircular bowls or three fan blades that rotate around the shaft. The center line of the semicircular bowl or the fan blade is arranged on the central axis of the pipeline. The tail end of 11 is fixedly connected, and rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com