A simulation test device for valve port characteristics of a continuous wave signal generator

A signal generator and simulation test technology, applied in measuring devices, instruments, buildings, etc., can solve the problems of rotary valve erosion, valve port over-flow area limited by space, large power consumption, etc., and achieve a large adjustable range of pressure. , reduce the number of experiments, the effect of strong purpose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

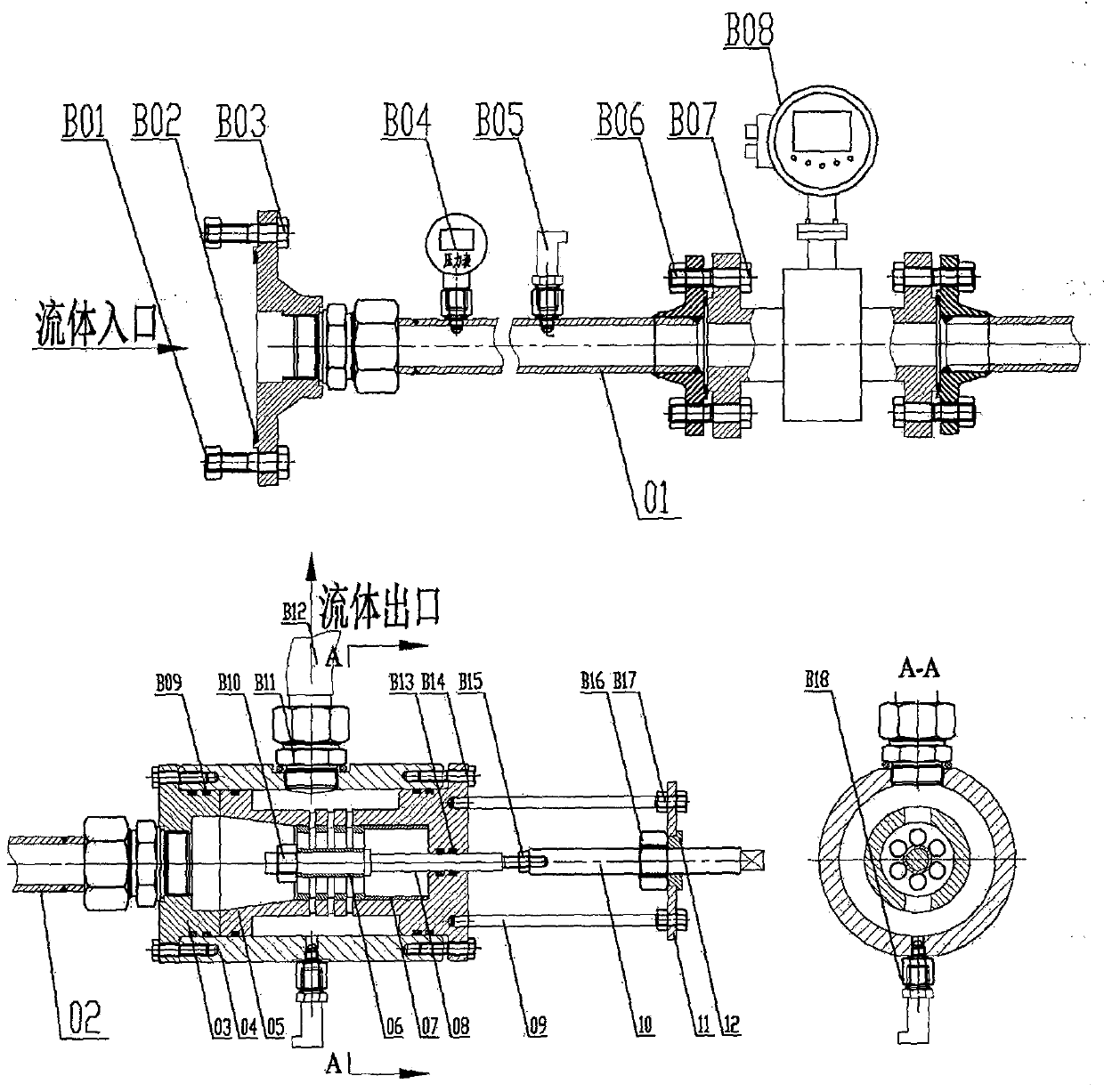

Embodiment Construction

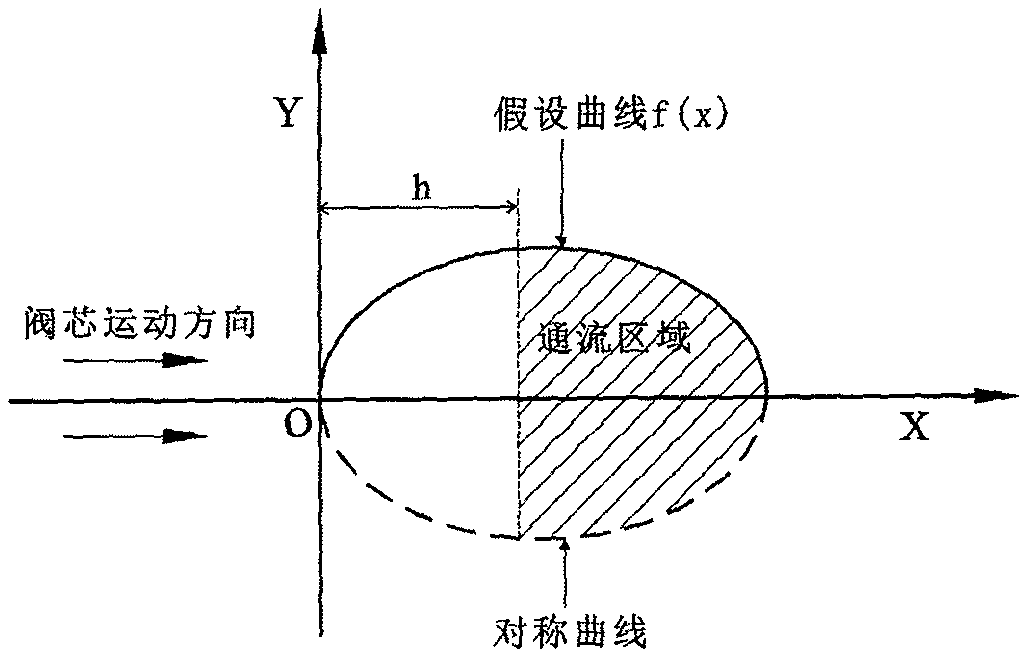

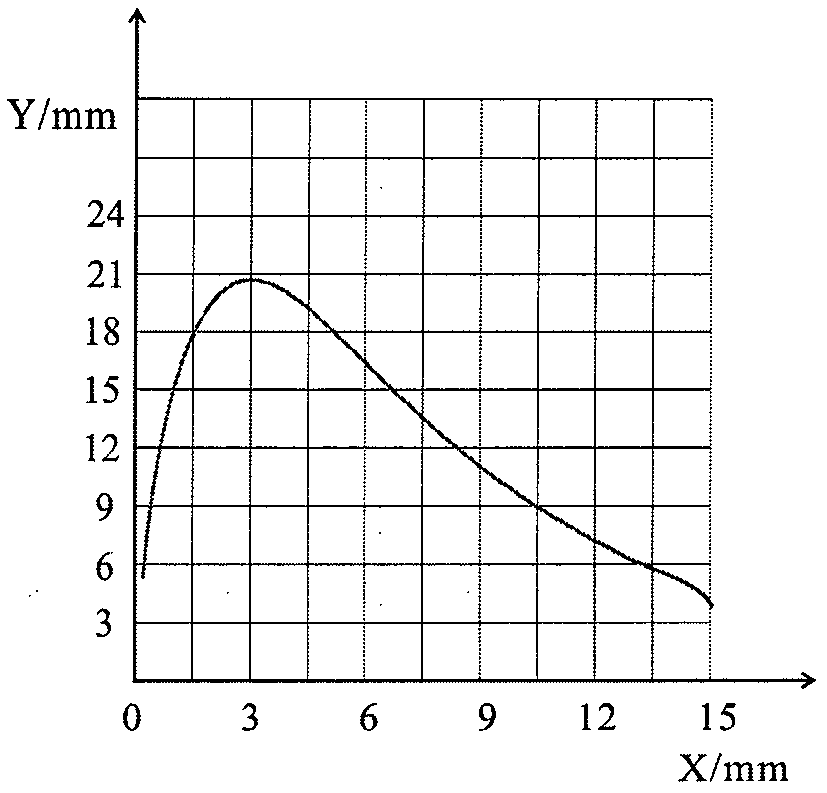

[0030] (1) Derivation based on the shape of the valve port that generates a continuous wave pressure signal. Parameters maximum and minimum pressure difference ΔPmax, ΔPmin, continuous pressure wave frequency Hz, spool reciprocating motion equation h=g(t), pump flow Q, drilling fluid density ρ, valve port flow coefficient Cd, number of single-layer valve ports n, The number of layers L of the valve port is a preset value, and Matlab is used for simulation calculation to obtain a certain valve port shape such as image 3 . The X-axis direction in the coordinates is the direction of the central axis of the spool, and a complete valve port includes the curve in the figure and a curve symmetrical to the curve about the X-axis;

[0031] (2) Carry out fitting processing according to the valve port shape deduced from the theory, and finally process the processed valve port shape on the pipe wall of the valve seat 05, and expand the valve port on the side of the valve seat pipe wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com