Six-parameter quantum inertial sensor and measuring method thereof

A technology of inertial sensor and measurement method, which is applied in directions such as navigation through speed/acceleration measurement, can solve the problems of cold atom gyroscopes such as large volume, difficulty in practical use, and large and complex overall structure, and achieve compact structure and good light transmission , the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

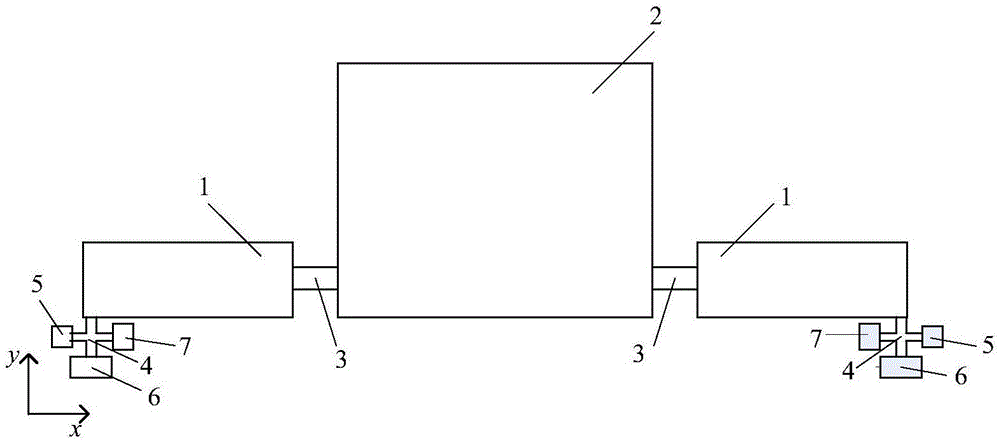

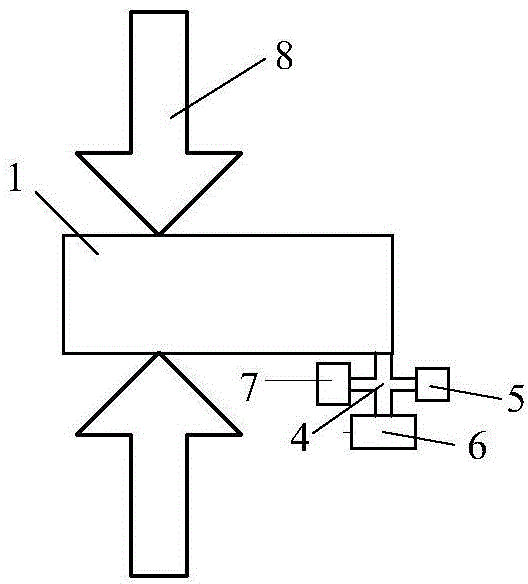

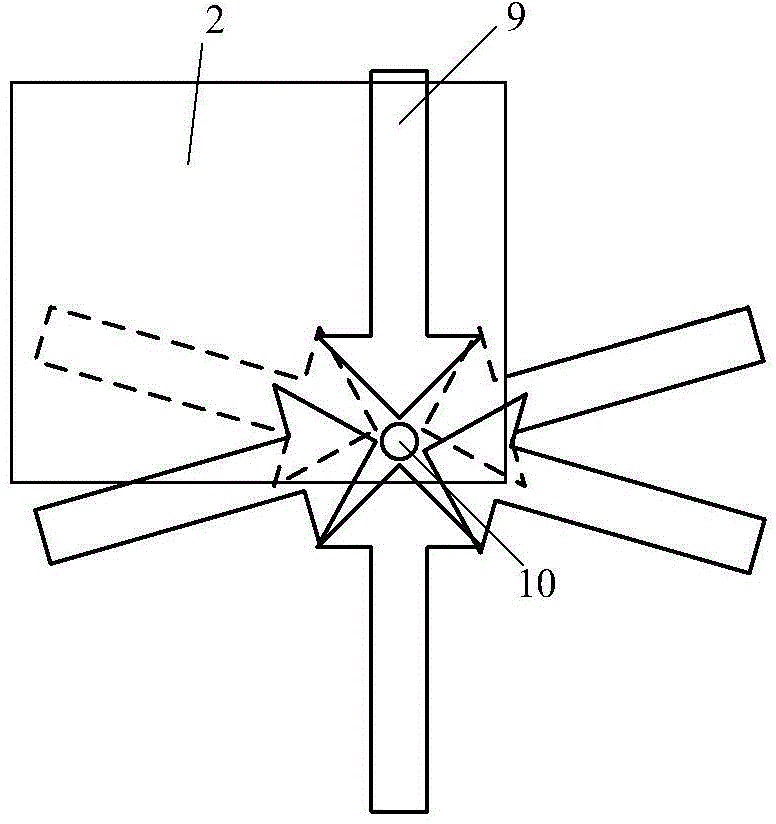

[0055] see figure 1 The six-parameter quantum inertial sensor of the present invention includes two two-dimensional glass-ceramic vacuum chambers 1, three-dimensional glass-ceramic vacuum chambers 2, a differential pump tube 3, a four-way joint 4, an ion pump 5 and an alkali metal source 6, Vacuum valve 7. In the present invention, the two two-dimensional glass-ceramic vacuum chambers 1 are respectively connected to the lower part of the three-dimensional glass-ceramic vacuum chamber 2 through the differential pump tube 3, leaving enough room for cold atomic groups to control. At the same time, alkali metal sources 6 are respectively connected through the four-way joints 4 to provide sufficient alkali metal gas to the two-dimensional glass-ceramic vacuum chamber 1 . The four-way joint 4 is also connected with an ion pump 5 and a vacuum valve 7 for vacuum tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com