Sheet material detection method

A detection method and plate technology, applied in the field of measurement, can solve problems such as simple structure, comprehensive measurement of plates, and unreasonable design, and achieve the effects of reasonable design, low manufacturing cost, and convenient measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

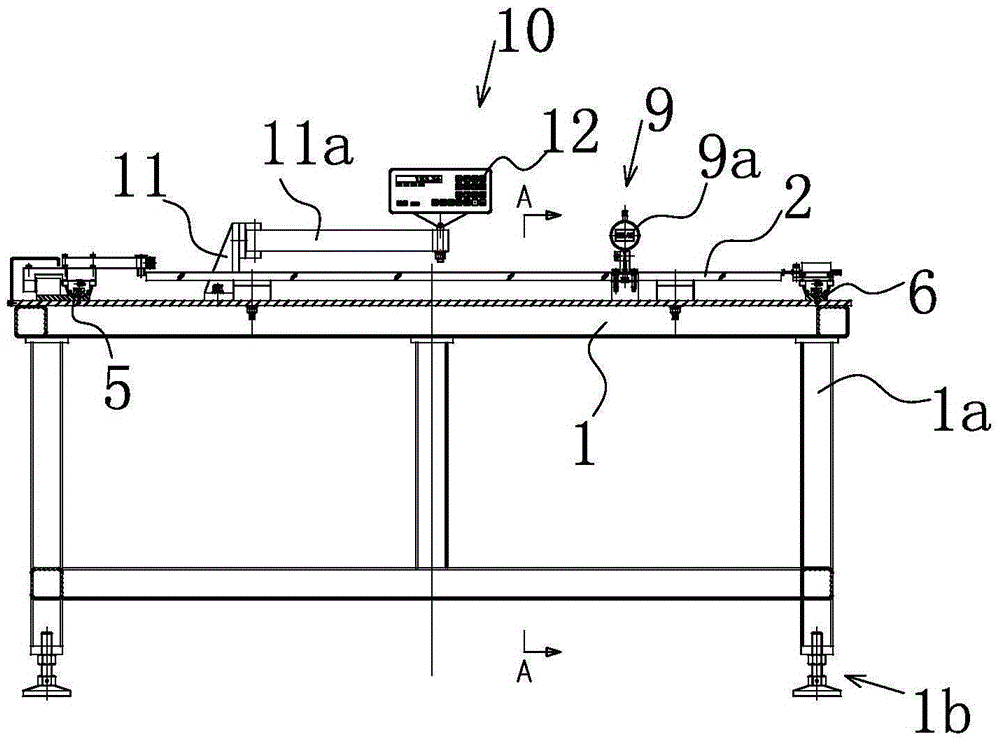

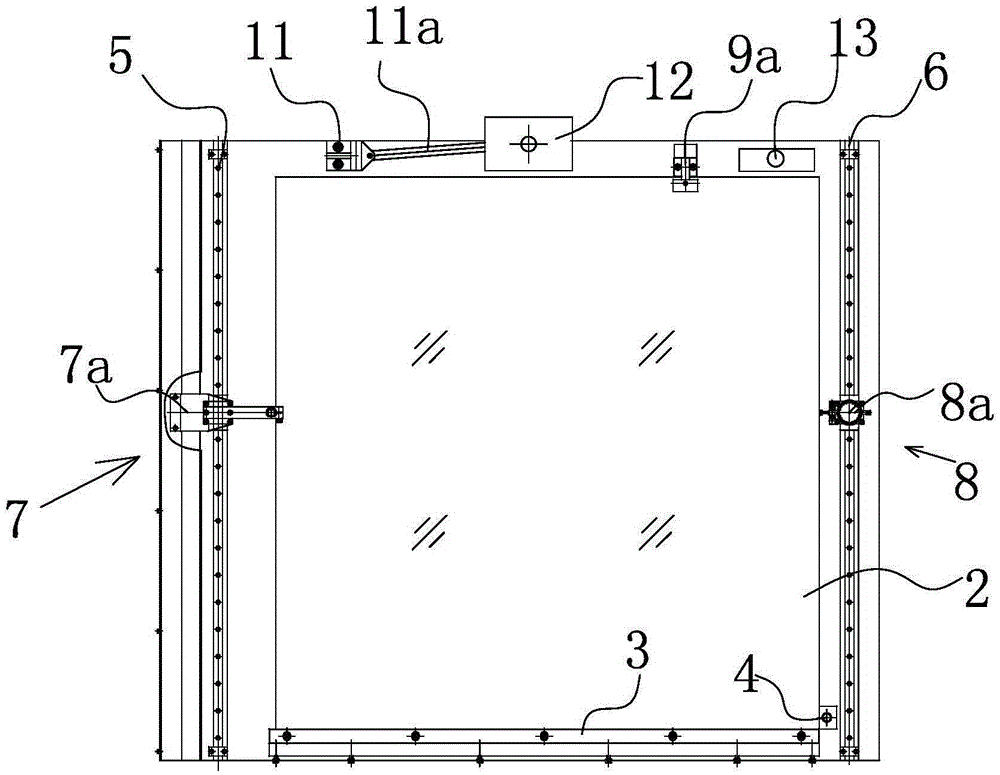

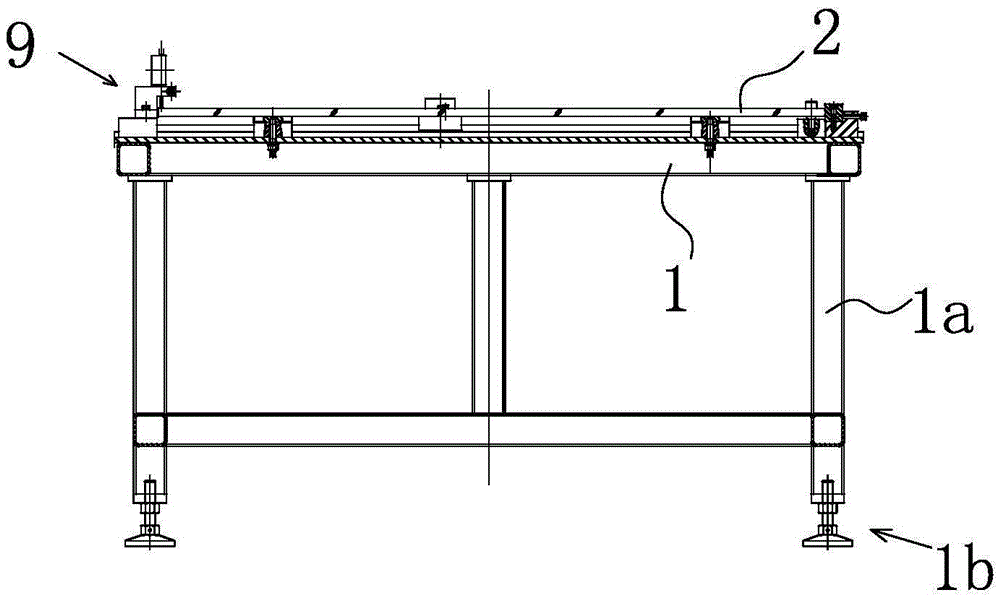

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] Such as Figure 1-3 as shown,

[0028] The plate detection method is characterized in that the method comprises the following steps:

[0029] A. Loading: Place the plate 2a to be tested on the detection platform 2 and make a cut edge of the plate 2a close to the reference ruler 3 and make a corner of the plate 2a stuck in the right angle, the plate to be tested The other shearing edge of 2a is located at the verticality detection mechanism 8;

[0030] B. Detection:

[0031] ①Length detection: move the length detection mechanism 7 to the cutting edge of the plate 2a where the perpendicularity detection mechanism 8 is located, and the length detection mechanism 7 sends the detected data to the display device 10 and displays the length data. If the length data exceeds If the length is within the range of the set value, the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com