Movable dust collecting cover having movable doors of blast furnace

A technology of movable door and blast furnace, which is applied in furnaces, furnace components, waste heat treatment, etc., to achieve the effect of convenient heat preservation treatment, easy cleaning, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

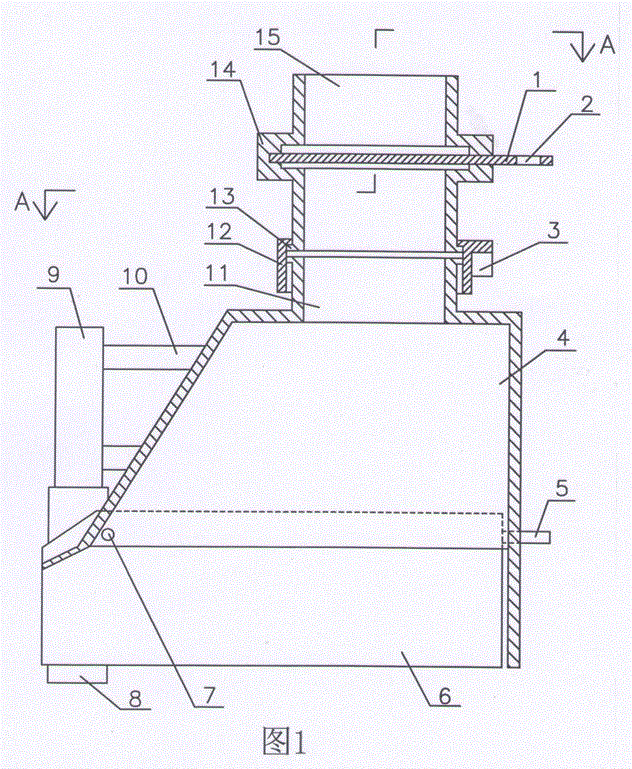

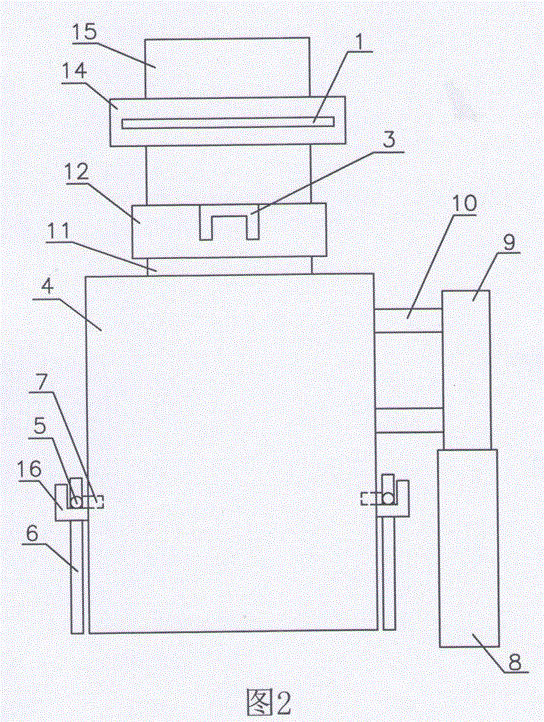

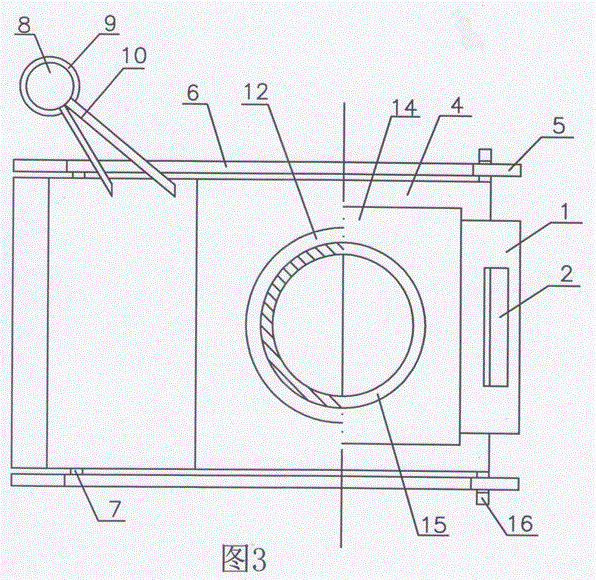

[0016] exist figure 1 , figure 2 , image 3 In the shown embodiment, the blast furnace is positioned at the left side of the gas collection hood 4, the upper part of the gas collection hood 4 is the lower exhaust pipe 11, the upper exhaust pipe 15 is arranged above the lower exhaust pipe 11, and the middle part of the upper exhaust pipe 15 There is board frame 14, and board 1 coincides with the slot in board frame 14, and the lower end of upper exhaust pipe 15 has pipeline edge 13, and trachea cover 12 is enclosed within the lower end of upper exhaust pipe 15, and trachea cover 12 is made of The pipeline at the lower end of the upper exhaust pipe 15 is supported along 13. The diameter of the lower part of the cylinder 8 is large, the diameter of the upper part of the cylinder 8 is small, the cylindrical sleeve 9 is set on the upper part of the cylinder 8, and a bearing is installed between the upper part of the cylinder 8 and the cylindrical sleeve 9, and the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com