Moisture chamber that can effectively regulate the humidity of fabrics

A fabric and moisturizing technology, applied in the field of moisturizing room, can solve the problems of high production cost, affecting the quality of finished products, high investment and operating costs, and achieve low cost, avoid easy blockage, and good rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

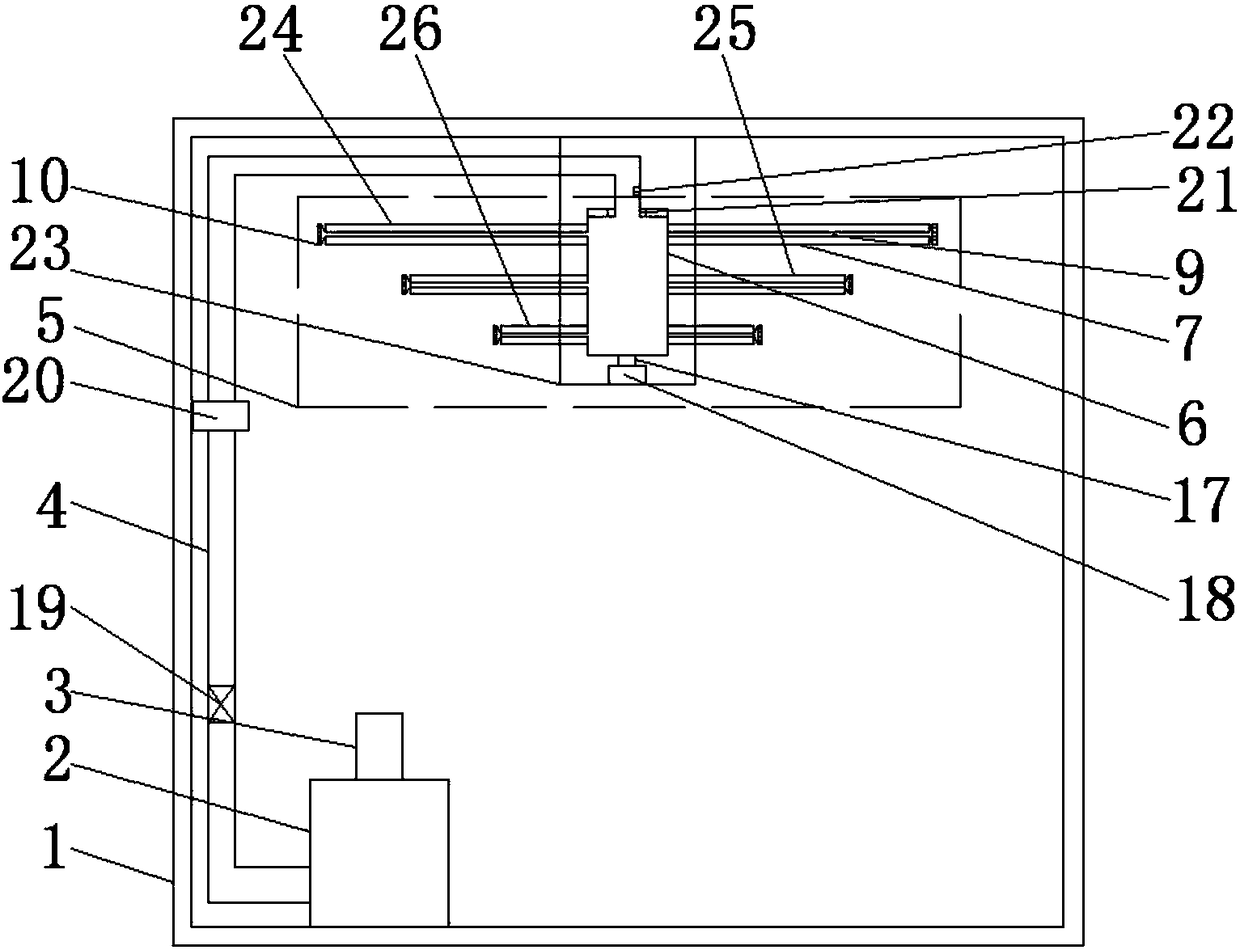

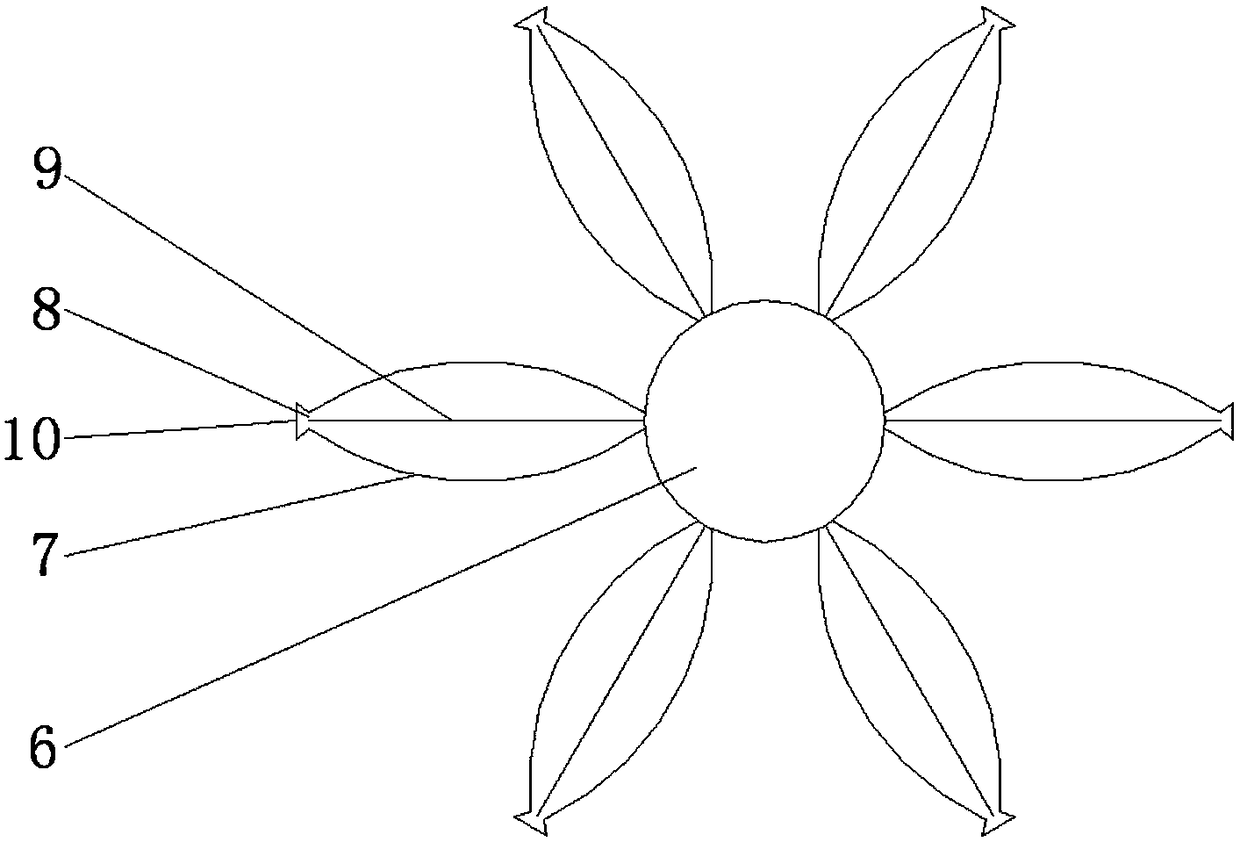

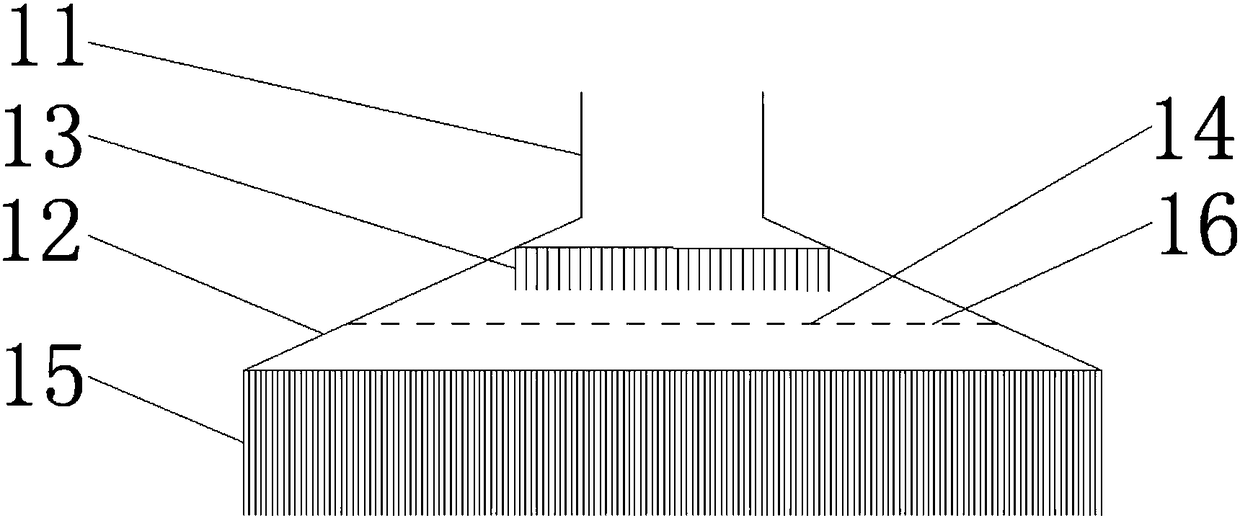

[0019] Example. A moisturizing room capable of effectively regulating the humidity of fabrics, constituted as figure 1 , figure 2 and image 3 As shown, the room body 1 is included, the room body 1 is provided with a constant temperature water tank 2, the constant temperature water tank 2 is provided with a pressure regulating pump 3, the constant temperature water tank 2 is connected with a pipeline 4, and the pipeline 4 is arranged along the edge of the room body 1 The pipeline 4 extends to the top of the room body 1, and the pipeline 4 on the top of the room body 1 is rotatably connected with a humidifying device 5; the humidifying device 5 includes a water storage tank 6, which is rotatably connected with the pipeline 4 and Connected, the periphery of the water storage tank 6 is sequentially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com