Wear-resistant and corrosion-resistant bearing

A corrosion-resistant, bearing technology, used in bearings, bearing components, shafts and bearings, etc., can solve the problems that bearings cannot adapt to temperature, load, lubrication conditions, low contact fatigue strength, poor life reliability, etc., to achieve wear resistance and Excellent toughness, good contact fatigue performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

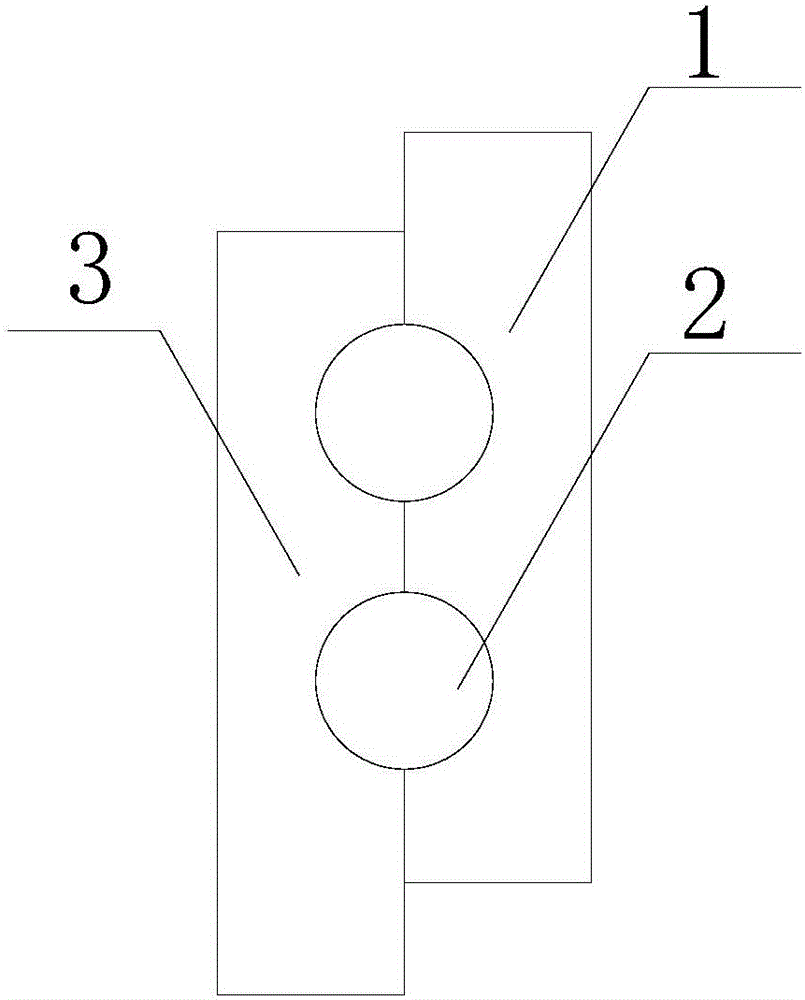

[0033] like figure 1 as shown, figure 1 It is a cross-sectional view of a wear-resistant and corrosion-resistant bearing proposed by the present invention.

[0034] refer to figure 1 , a wear-resistant and corrosion-resistant bearing proposed by the present invention includes a bearing outer ring 1, a rolling ball 2, and a bearing inner ring 3, and the raceways of the bearing outer ring 1 and the bearing inner ring 3 are double-raceway structures; In the radial section, the distance between the centers of the two raceways is 84mm; the radius of curvature of any raceway is 30.8mm, the radius of the ball 2 is 29.6mm, and the bearing contact angle is 50°.

[0035] The components of the bearing inner ring 3 include by weight percentage: C: 0.55%, Si: 0.40%, N: 0.15%, B: 0.20%, V: 0.3349%, W: 0.10%, Mo: 0.23%, Nb: 0.08 %, Al: 0.35%, Cr: 3.04%, Y: 0.12%, S≤0.015%, P≤0.02%, and the balance is Fe.

[0036] The preparation process of the bearing inner ring 3 includes: melting, pour...

Embodiment 2

[0042] A wear-resistant and corrosion-resistant bearing proposed by the present invention includes a bearing outer ring 1, a rolling ball 2, and a bearing inner ring 3, and the raceways of the bearing outer ring 1 and the bearing inner ring 3 are double-raceway structures; In the radial section, the distance between the centers of the two raceways is 84mm; the radius of curvature of any raceway is 30.8mm, the radius of the ball 2 is 29.6mm, and the bearing contact angle is 50°.

[0043] The components of the bearing inner ring 3 include by weight percentage: C: 0.65%, Si: 0.20%, N: 0.25%, B: 0.10%, V: 0.3709%, W: 0.20%, Mo: 0.20%, Nb: 0.12 %, Al: 0.25%, Cr: 3.36%, Y: 0.15%, S≤0.015%, P≤0.02%, and the balance is Fe.

[0044] The preparation process of the bearing inner ring 3 includes: melting, pouring and heat treatment.

[0045] Heat treatment includes:

[0046] Austenitizing treatment: raise the temperature of the poured inner ring body to 600°C, hold it for 3 hours, then ...

Embodiment 3

[0050] A wear-resistant and corrosion-resistant bearing proposed by the present invention includes a bearing outer ring 1, a rolling ball 2, and a bearing inner ring 3, and the raceways of the bearing outer ring 1 and the bearing inner ring 3 are double-raceway structures; In the radial section, the distance between the centers of the two raceways is 84mm; the radius of curvature of any raceway is 30.8mm, the radius of the ball 2 is 29.6mm, and the bearing contact angle is 50°.

[0051] The components of the bearing inner ring 3 include by weight percentage: C: 0.58%, Si: 0.35%, N: 0.18%, B: 0.18%, V: 0.3436%, W: 0.13%, Mo: 0.22%, Nb: 0.09 %, Al: 0.32%, Cr: 3.1276%, Y: 0.13%, S≤0.015%, P≤0.02%, and the balance is Fe.

[0052] The preparation process of the bearing inner ring 3 includes: melting, pouring and heat treatment.

[0053] Heat treatment includes:

[0054] Austenitizing treatment: raise the temperature of the poured inner ring body to 620°C, keep it warm for 2.2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com