A large wind turbine blade hinge mechanism

A technology for wind turbines and hinge mechanisms, which is applied to wind turbines, wind turbines consistent with the wind direction, and wind turbine control, etc., can solve the problems of weak power regulation capability, difficult design and manufacturing, and high manufacturing and maintenance costs, and achieves The effect of stable power, easy starting and large starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

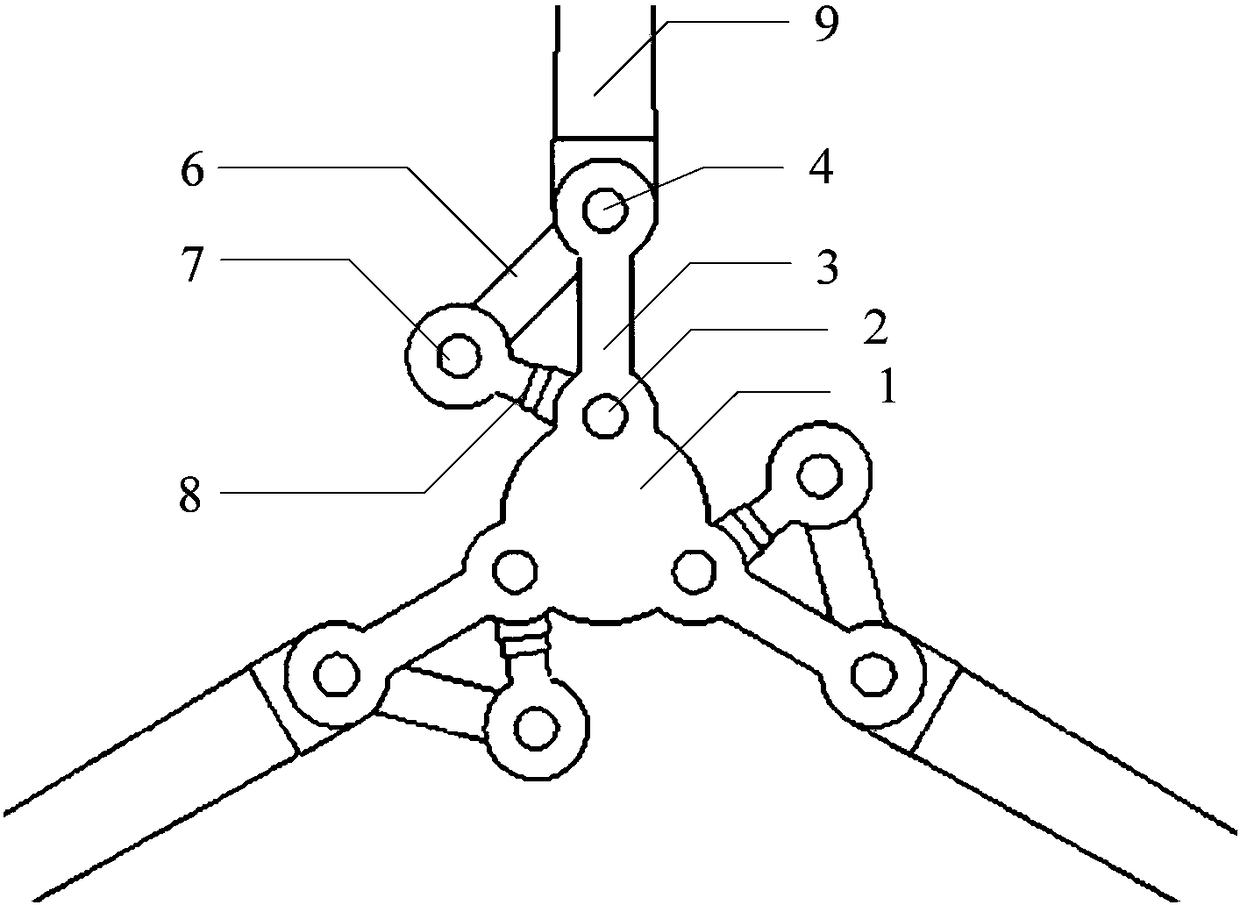

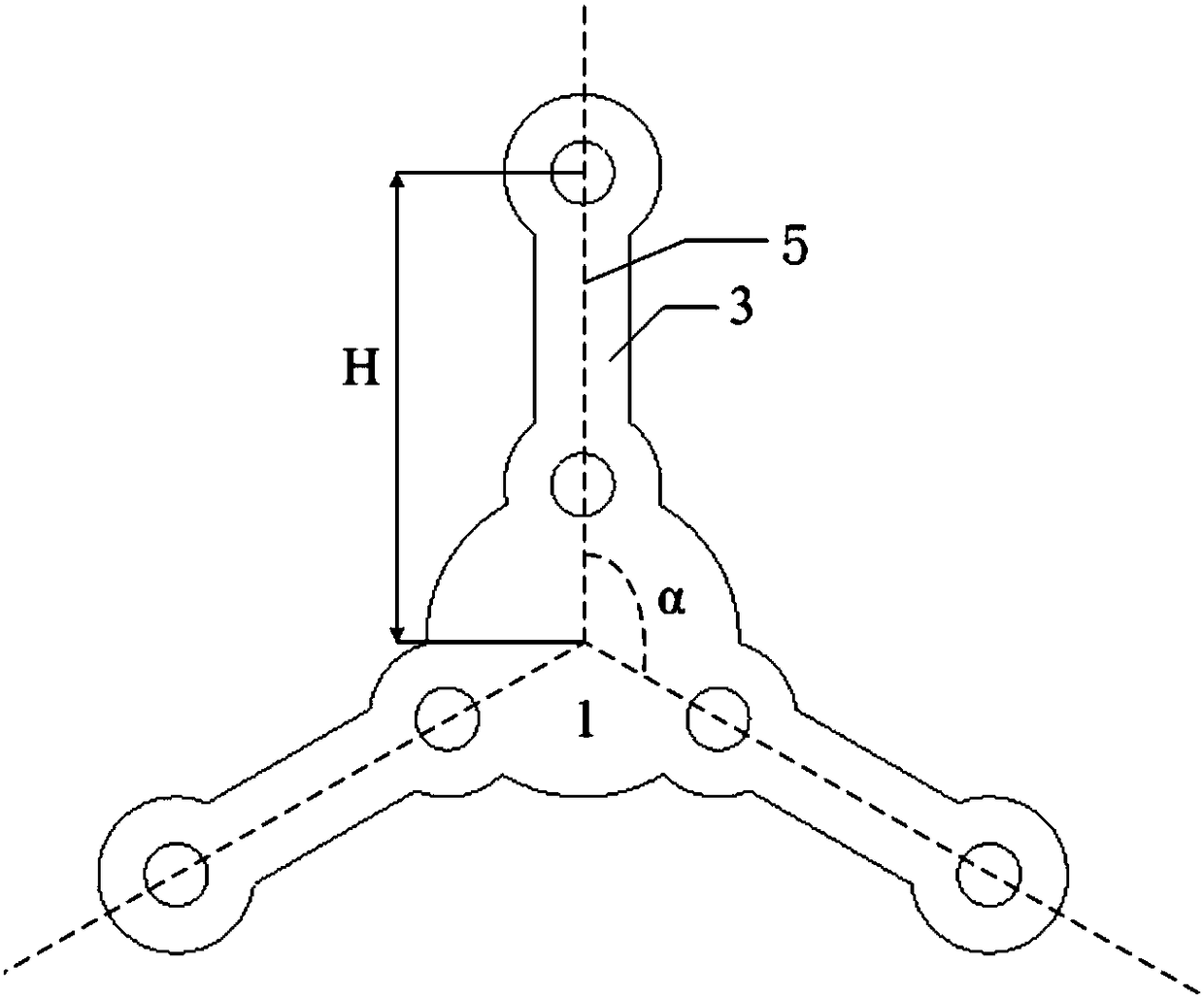

[0021] like figure 1 As shown, a large-scale wind turbine blade hinge mechanism includes a hub 1, and the hub 1 has three hub cantilevers 3 evenly distributed along the circumferential direction, and each hub cantilever 3 has a hinge hole at the top and root, and the hub cantilever 3 roots are rigid to the hub 1. Connected together, the top of the hub cantilever 3 is hinged through the second pin 4 and the top hinge hole of the support arm 6 of the paddle 9, and the bottom hinge hole of the support arm 6 is hinged with the top of the hydraulic cylinder 8 through the third pin 7. The bottom end of the cylinder 8 is hinged with the hinge hole at the root of the hub cantilever 3 through the first pin shaft 2, and the hydraulic cylinder 8, the hub cantilever 3 and the support arm 6 form a triangle connection.

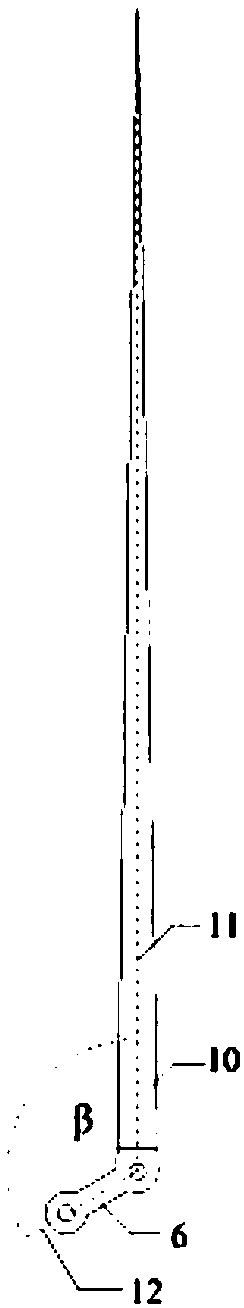

[0022] like figure 2 As shown, the blade 9 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com