A method for strengthening concrete rods of substation structure supports

A technology of concrete poles and frame supports, applied in building construction, building maintenance, construction, etc., can solve problems such as high-voltage short-circuit accidents of carbon fiber reinforcement methods, economic construction losses in power supply areas, and inability to achieve non-stop reinforcement, etc., and achieve the construction approval process Simple and time-saving, avoiding the discharge of construction waste, and shortening the renovation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] A method for reinforcing concrete rods of substation structure supports, the main steps of which are as follows:

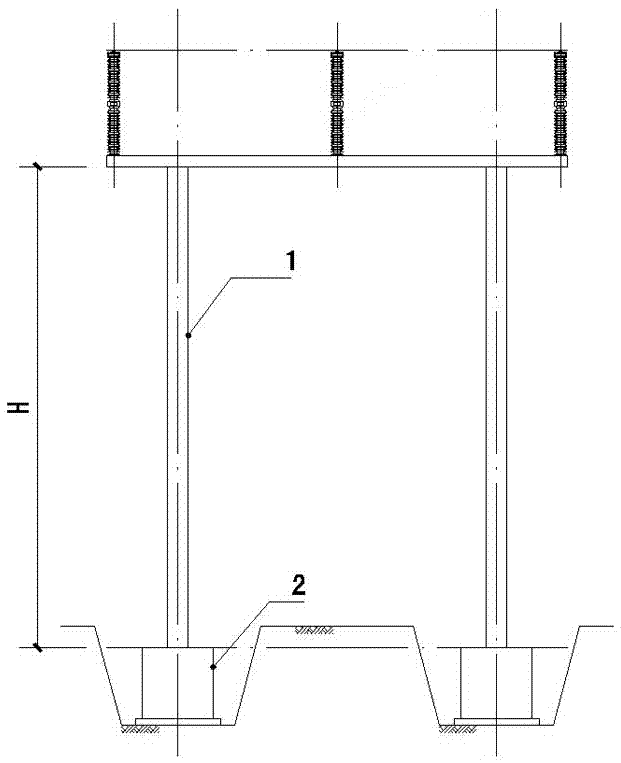

[0044] 1) if figure 1 As shown, excavate the independent foundation 2 of the substation structure support concrete pole 1, clean the surface of the independent foundation 2 after excavation, chisel, and spray water to moisten;

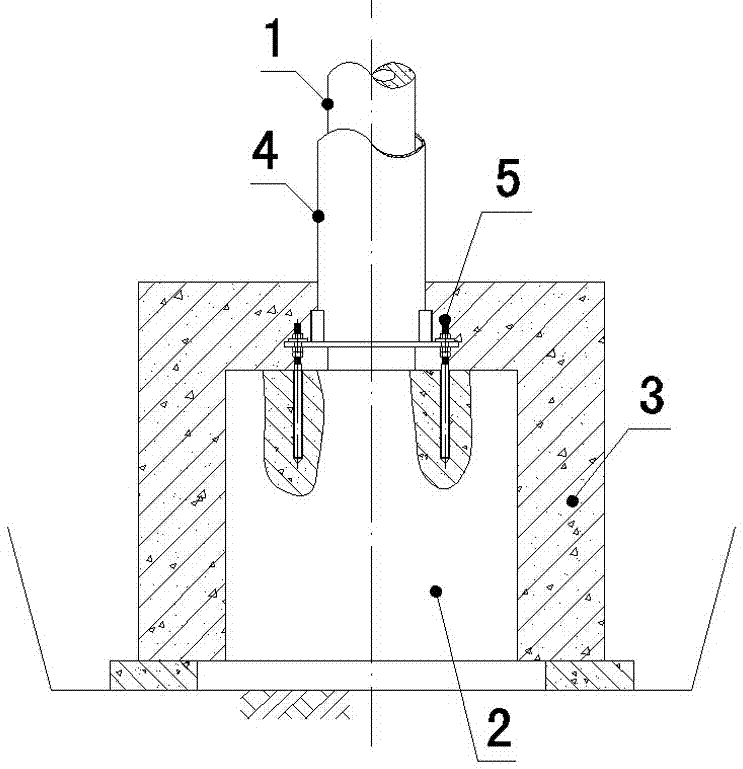

[0045] 2) if figure 2As shown, the column foundation steel pipe 4 is installed at the lower end of the concrete pole 1, and is anchored in the independent foundation 2 by the planting bolt 5. The column foundation steel pipe 4 is composed of two semicircular steel pipes, and reinforced concrete 3 is poured on the upper part and surroundings of the independent foundation 2, Make the independent foundation and reinforced concrete firmly combined;

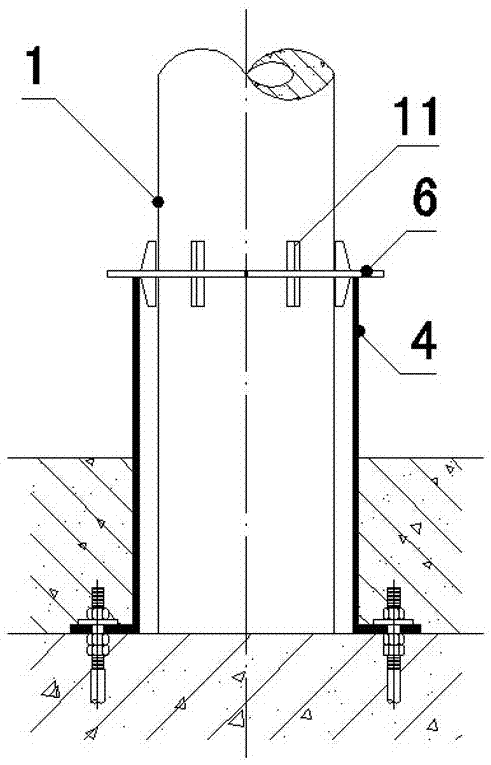

[0046] 3) if Figure 3-5 As shown, a positioning ring plate 6 is placed on the upper end of the column foundation steel pipe 4, and the first section of reinforced steel pipe 7 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com