Accessory for preventing union dyeing

An auxiliary material and anti-mixing technology, which is applied in the direction of textiles and papermaking, fiber treatment, non-woven fabrics, etc., can solve the problems of high-end product quality and grade damage, affecting the washing effect, and the effect is not obvious, so as to ensure quality and grade, improve Convenience and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

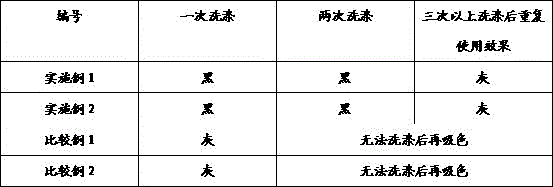

Examples

Embodiment 1

[0025] The percentage by weight is 2% trimethylbenzyl ammonium chloride, 5% diethyl-2,3-epoxypropyl-[3-(methyldimethoxy)] silicon propyl ammonium chloride, 2 % chitosan quaternary ammonium salt, 1.5% sodium polyacrylate, 0.53% phthalate, 1.2% 2-(4-thiazolyl) benzimidazole, mix the rest of cotton pulp, heat up to 50-60°C Keep warm for 60-80 minutes, drain and clean; produce the obtained cotton pulp into spunlace non-woven fabrics by spunlace method; cut the non-woven fabrics into long cloth strips with a width of 1 meter and roll them into rollers; weight) of oxalic acid solution into the dipping tank at a constant speed, and at the same time, the long cloth strips pass through the dipping tank at a constant speed of 3-5m / min; the non-woven fabric strips pass through the oven channel, the baking temperature is 105-120 ° C, and the baking time is controlled. Make the liquid content lower than 6%; naturally cool and dry, cut into small pieces, and pack to obtain the finished prod...

Embodiment 2

[0027] The percentage by weight is 4% trimethylbenzyl ammonium chloride, 5.5% epoxy silicone quaternary ammonium salt, 2.3% chitosan quaternary ammonium salt, 3.2% sodium polyacrylate, 3% phthalate, 2 % 2-(4-thiazolyl)benzimidazole, mixed with the remaining amount of cotton pulp, warmed up to 55°C and kept warm for 68 minutes, drained and cleaned; the obtained cotton pulp was produced into spunlace non-woven fabric by spunlace method; the non-woven The cloth is cut into long strips with a width of 1-1.5 meters and rolled into a drum, and the oxalic acid solution with a concentration of 8% (weight) is added to the dipping tank at a constant speed, and the long strips are dipped at a constant speed of 3.4m / min. Groove; the non-woven fabric strips pass through the oven passage, the baking temperature is 105-120 ° C, the baking time is controlled to make the liquid content less than 8%; natural cooling and drying, cutting into small pieces, packaging to obtain the finished product....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com