Ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying

A technology of vacuum coating and electrostatic spraying, applied in coatings, powder coatings, polyester coatings, etc., can solve problems such as hindering the development of UV-curing vacuum coating coatings, poor spraying quality at the edges of products, and low production efficiency of enterprises. The effect of focusing on excellent, improving light curing speed and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

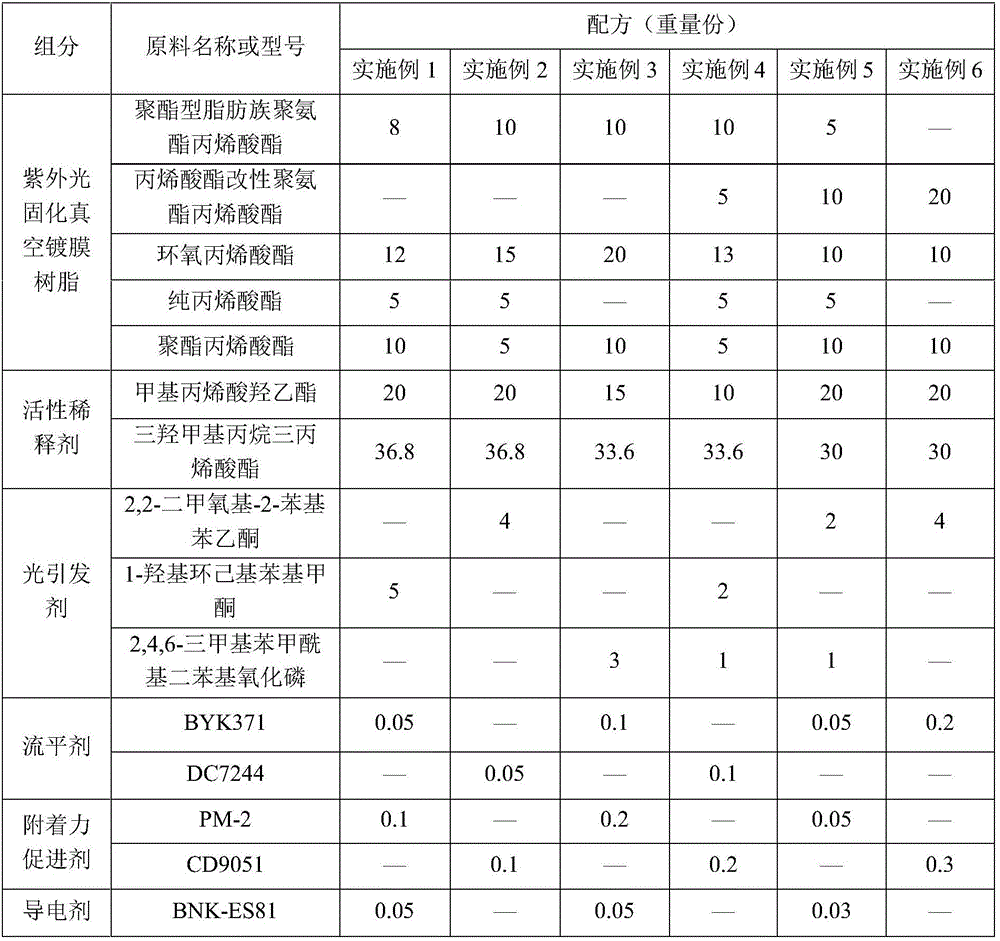

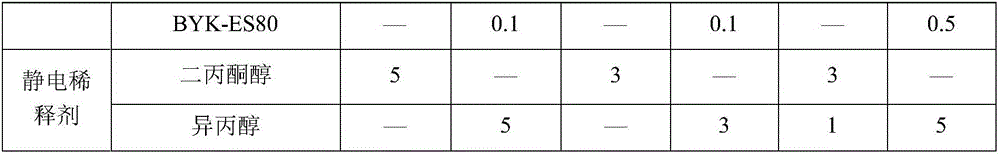

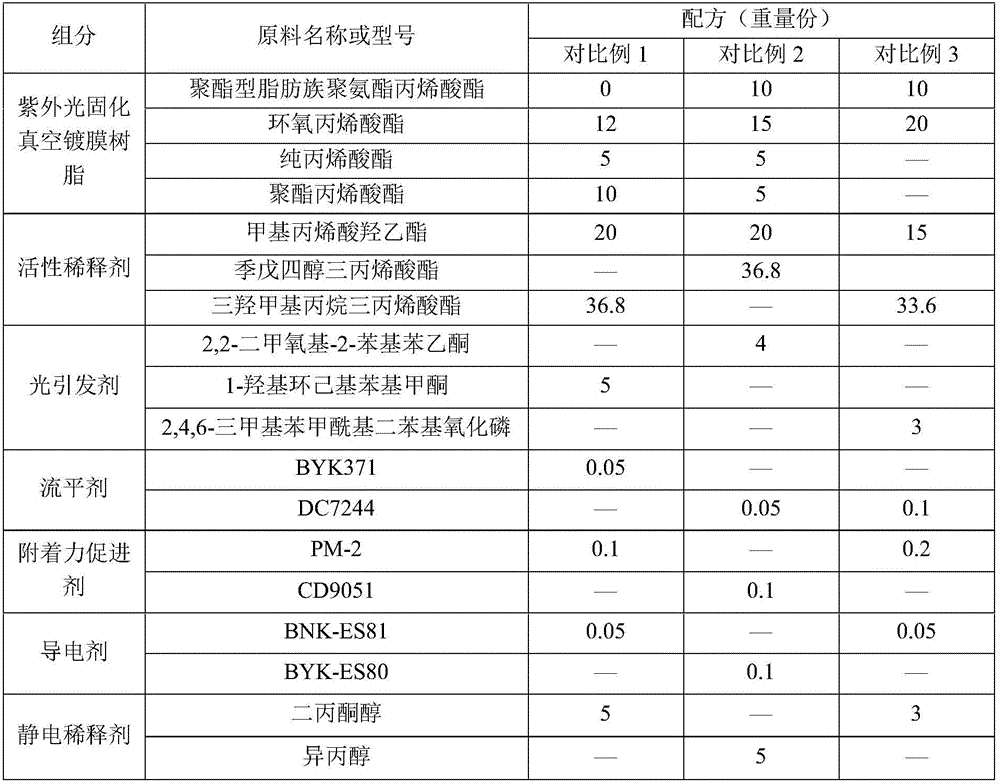

[0035] S1. According to the ratio shown in Table 1, add the UV-curable vacuum coating resin, reactive diluent, and photoinitiator into the stirring tank and stir for 3 hours to disperse evenly;

[0036] S2. Add a leveling agent, an adhesion promoter, a conductive agent, and an electrostatic diluent, and stir for 1 hour to obtain a UV-curable vacuum coating metal primer that can be electrostatically sprayed.

Embodiment 2

[0038] S1. According to the ratio shown in Table 1, add the UV-curable vacuum coating resin, reactive diluent, and photoinitiator into the stirring tank and stir for 2 hours to disperse evenly;

[0039] S2. Add a leveling agent, an adhesion promoter, a conductive agent, and an electrostatic diluent, and stir for 2 hours to obtain a UV-curable vacuum coating metal primer that can be electrostatically sprayed.

Embodiment 3

[0041] S1. According to the ratio shown in Table 1, add the UV-curable vacuum coating resin, reactive diluent, and photoinitiator into the stirring tank and stir for 4 hours to disperse evenly;

[0042] S2. Add a leveling agent, an adhesion promoter, a conductive agent, and an electrostatic diluent, and stir for 1 hour to obtain a UV-curable vacuum coating metal primer that can be electrostatically sprayed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com