High-stability styrene butadiene latex and preparation method thereof

A technology of styrene-butadiene latex and high stability, applied in the field of latex, can solve the problems of low stability and easy to be affected by heavy metal ions, and achieve the effect of good waterproofness and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

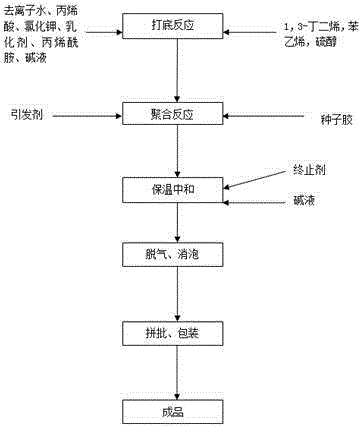

Image

Examples

Embodiment 1

[0022] In the embodiment of the present invention, a kind of high-stability styrene-butadiene latex, the raw material according to weight comprises: deionized water 9900kg, styrene 4400kg, 1,3-butadiene 6900kg, acrylic acid 340kg, initiator 45kg, potassium chloride 20kg, emulsifier 10kg, lye 180kg, terminator 15kg, mercaptan 100kg, seed glue 220kg, acrylamide 70kg.

[0023] The preparation method of the styrene-butadiene latex of described high stability, concrete steps comprise:

[0024] (1) Primer reaction: inject 1,3-butadiene, styrene and mercaptan into the oil phase tank through a metering pump to obtain an oil phase liquid; mix deionized water, acrylic acid, potassium chloride, emulsifier, Acrylamide and lye are poured into the water phase kettle to obtain the water phase liquid;

[0025] (2) Polymerization reaction: the specific steps include,

[0026] a. Pour deionized water into the reactor, replace the reactor with steam, and evacuate the reactor to -0.1MPa;

[00...

Embodiment 2

[0036] In the embodiment of the present invention, a kind of high stability styrene-butadiene latex, the raw material according to weight comprises: deionized water 10000kg, styrene 4500kg, 1,3-butadiene 7000kg, acrylic acid 350kg, initiator 50kg, potassium chloride 25kg, emulsifier 12kg, lye 200kg, terminator 20kg, mercaptan 120kg, seed glue 250kg, acrylamide 75kg.

[0037] The preparation method of the styrene-butadiene latex of described high stability, concrete steps comprise:

[0038] (1) Primer reaction: inject 1,3-butadiene, styrene and mercaptan into the oil phase tank through a metering pump to obtain an oil phase liquid; mix deionized water, acrylic acid, potassium chloride, emulsifier, Acrylamide and lye are poured into the water phase kettle to obtain the water phase liquid;

[0039] (2) Polymerization reaction: the specific steps include,

[0040] a. Pour deionized water into the reactor, replace the reactor with steam, and evacuate the reactor to -0.09MPa;

[...

Embodiment 3

[0050] In the embodiment of the present invention, a kind of high-stability styrene-butadiene latex, the raw material according to weight comprises: deionized water 10100kg, styrene 4600kg, 1,3-butadiene 7100kg, acrylic acid 360kg, initiator 55kg, potassium chloride 30kg, emulsifier 15kg, lye 220kg, terminator 25kg, mercaptan 140kg, seed glue 270kg, acrylamide 80kg.

[0051] The preparation method of the styrene-butadiene latex of described high stability, concrete steps comprise:

[0052] (1) Primer reaction: inject 1,3-butadiene, styrene and mercaptan into the oil phase tank through a metering pump to obtain an oil phase liquid; mix deionized water, acrylic acid, potassium chloride, emulsifier, Acrylamide and lye are poured into the water phase kettle to obtain the water phase liquid;

[0053] (2) Polymerization reaction: the specific steps include,

[0054] a. Pour deionized water into the reactor, replace the reactor with steam, and evacuate the reactor to -0.08MPa;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com