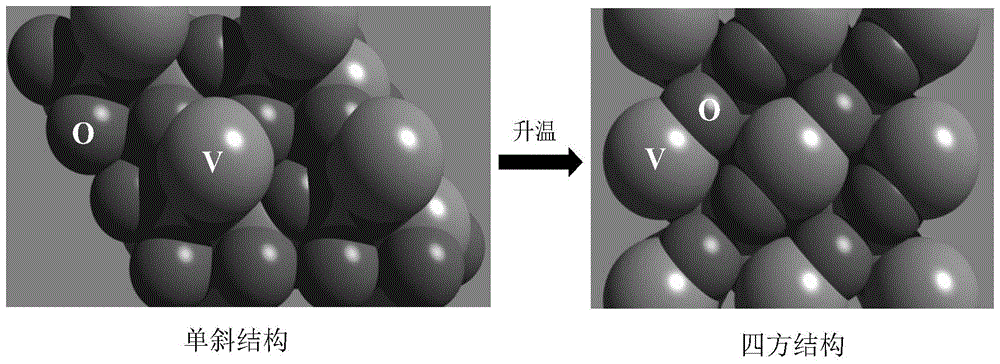

Preparation method for thermally-induced infrared-emission-rate-variable vanadium dioxide thin sheet

A technology of infrared emissivity and vanadium dioxide, which is applied in the field of inorganic functional materials, can solve the problems of small sudden change value of coating emissivity, influence infrared emissivity, affect performance and other problems, achieve small infrared emissivity, reduce preparation time, The effect of reducing reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of the vanadium dioxide thin sheet with thermally variable infrared emissivity of the present invention, comprising the following steps:

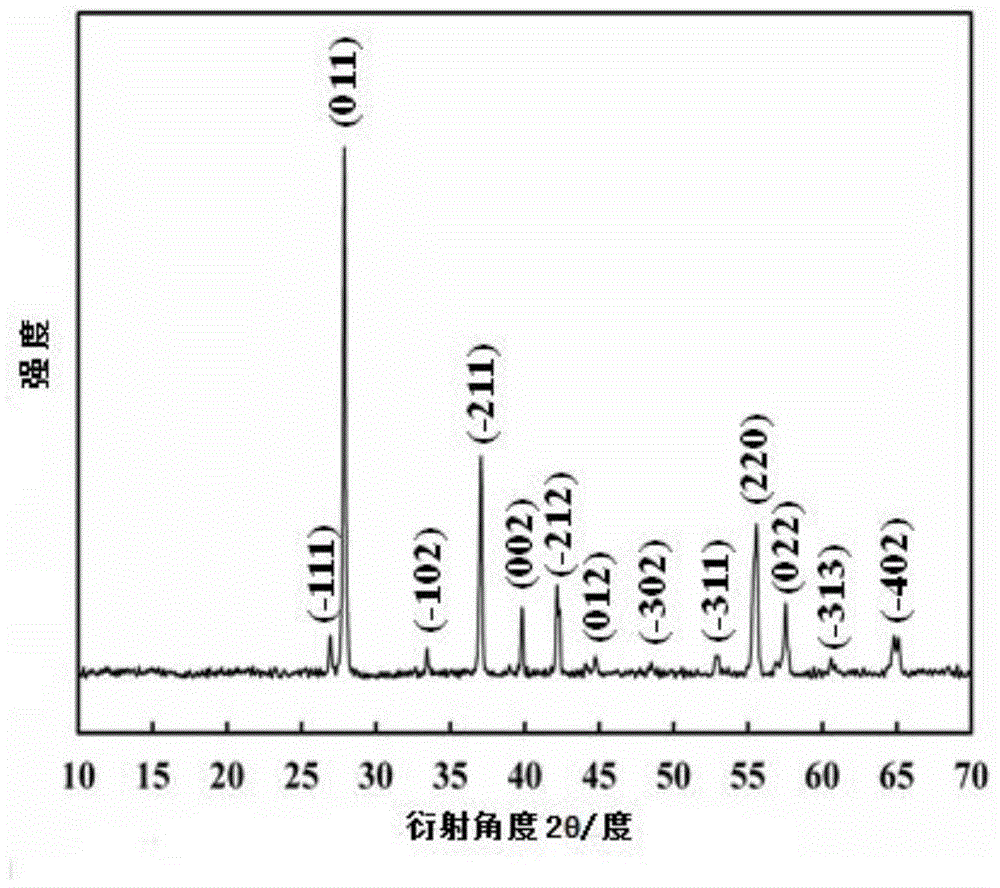

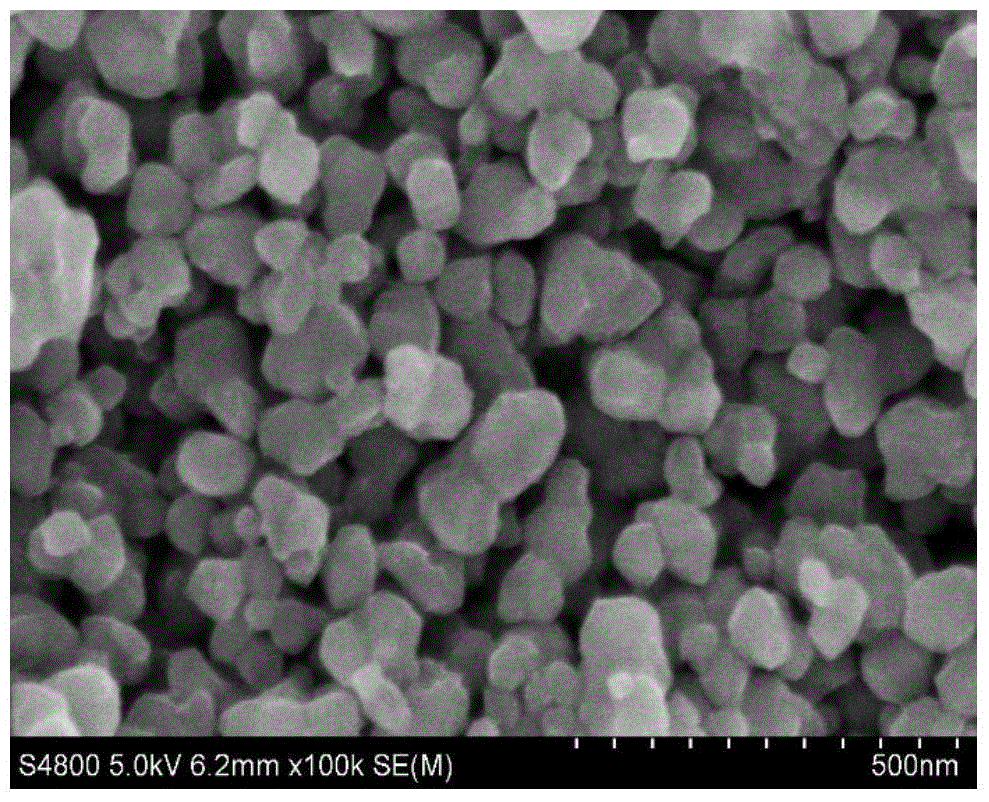

[0034] (1) Add 1.76g (0.015mol) of ammonium metavanadate and 1.58g (0.0082mol) of citric acid into 70ml of deionized water for magnetic stirring and mixing to form a homogeneous solution for 30 minutes; then the obtained solution Transfer to a 100ml hydrothermal kettle and react at 245°C for 16h;

[0035] (2) After the reaction is completed, the product is taken out after the hydrothermal kettle is naturally cooled, and the obtained product is first centrifuged, and then the product obtained after the centrifugation is alternately washed three times with deionized water and absolute ethanol, and finally heated at 60°C Carry out vacuum drying, drying time is 12h, obtains VO 2 Powder;

[0036] (3) Take 0.6g of VO obtained in step (2) 2 The powder is pressed into a sheet with a diameter of 20mm (referred to as a ...

Embodiment 2

[0041] A preparation method of the vanadium dioxide thin sheet with thermally variable infrared emissivity of the present invention, comprising the following steps:

[0042] (1) Add 1.76g (0.015mol) of ammonium metavanadate and 1.58g (0.0082mol) of citric acid into 70ml of deionized water for magnetic stirring and mixing to form a homogeneous solution for 30 minutes; then the obtained solution Transfer to a 100ml hydrothermal kettle and react at 285°C for 8h;

[0043] (2) After the reaction is completed, take out the product after the hydrothermal kettle cools down naturally, centrifuge the obtained product first, then wash the product obtained after the centrifugation with deionized water and absolute ethanol alternately three times, and finally put it under 80°C Carry out vacuum drying, drying time is 10h, obtains VO 2 Powder;

[0044] (3) Take 0.6g of VO obtained in step (2) 2 The powder is pressed into a sheet with a diameter of 20 mm by a tablet press under a pressure ...

Embodiment 3

[0047] A preparation method of the vanadium dioxide thin sheet with thermally variable infrared emissivity of the present invention, comprising the following steps:

[0048] (1) Add 2.07g (0.015mol) of potassium metavanadate and 3.15g (0.0164mol) of citric acid into 60ml of deionized water for magnetic stirring and mixing to form a uniform solution for 30 minutes; then the obtained solution Transfer to a 100ml hydrothermal kettle and react at 285°C for 12h;

[0049] (2) After the reaction is completed, the product is taken out after the hydrothermal kettle is naturally cooled, and the obtained product is first centrifuged, and then the product obtained after the centrifugation is alternately washed three times with deionized water and absolute ethanol, and finally heated at 70°C Carry out vacuum drying, drying time is 11h, obtains VO 2 Powder;

[0050] (3) Take 0.8g of VO obtained in step (2) 2 The powder is pressed into a sheet with a diameter of 20 mm by a tablet press un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com