Dairy farm wastewater treatment system and treatment method

A wastewater treatment system and wastewater treatment technology, applied in the field of environmental engineering, can solve the problems of substandard nitrogen and phosphorus content in effluent, difficult wastewater treatment, poor treatment effect, etc., and achieve less excess sludge, good economic and environmental benefits. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The waste water is lifted into the regulating tank, and the high-concentration lift pump (flow rate 30m 3 / h, head 15.0m, power 3.0kW, equipped with liquid level gauge, flowmeter, blast stirring). The regulating tank adopts reinforced concrete structure, with an effective volume of 430m 3 , The hydraulic retention time is 34 hours.

[0050] The waste water is fed to the screw pump through the filter press (flow rate 5-51m 3 / h, head 120.0m, power 22.0kW, frequency conversion speed regulation) into the automatic box-type diaphragm filter press, the filter press model is XMZG200 / 1250, and the filtration area is 200m 2 , the volume of the filter chamber is 4m 3 , the moisture content of the filter cake is 65-75%, and the power is 5.5kW.

[0051] The first anaerobic tank, design parameters: L×W×H=12.5m×8.5m×12m, quantity 2 (parallel connection), total effective volume is 2400m 3 , the volume load is 3.125kgCOD / m 3 ·d, the reaction temperature is controlled at 30°C±1. ...

Embodiment 2

[0057] Example 2 Dairy Farm Wastewater Treatment

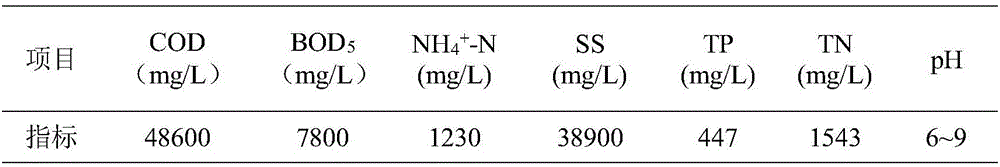

[0058] Apply the method of Embodiment 1 of the present invention to treat the wastewater from the Jinshan Dairy Farm of Shanghai Guangming Holstein Animal Husbandry Co., Ltd. The wastewater quality is shown in Table 1:

[0059] Table 1 Dairy farm wastewater quality

[0060]

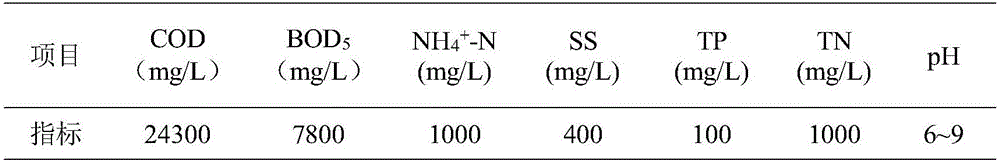

[0061] The pretreated dairy farm wastewater enters the filter press through the feed pump for dehydration, and the mud cake is discharged; the filtrate further passes through the first anaerobic tank to remove organic matter; the anaerobic effluent further passes through the second anaerobic tank, anoxic tank, Aerobic tank, sedimentation tank, aerated biological fluidized bed, air flotation tank to remove nitrogen, phosphorus and remaining organic matter, in which part of the sludge in the sedimentation tank is returned to the second anaerobic tank, part of the sludge is discharged from the system, and the nitrification liquid in the aerobic tank Par...

Embodiment 3

[0075] Example 3 Dairy Farm Wastewater Treatment System

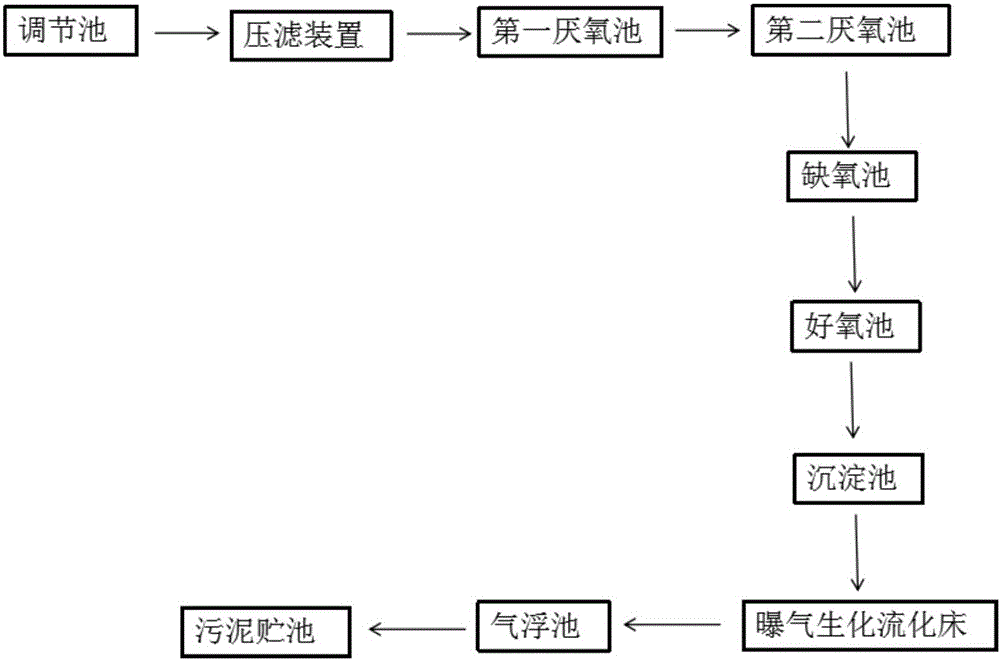

[0076] The dairy farm wastewater treatment system of the present invention is sequentially provided with: a regulating tank, a filter press device, a first anaerobic tank, a second anaerobic tank, an anoxic tank, an aerobic tank, a sedimentation tank, an aerated biological fluidized bed, Air flotation tank, sludge storage tank.

[0077] Wherein, an aeration device is provided in the regulating tank; a three-phase separator is provided on the upper part of the reactor of the first anaerobic tank, a gas collection pipe is provided on the top, a sludge discharge device is provided on the lower part, and a reactor is provided inside the reactor. Internal reflux pipeline; the filter press is an automatic box-type diaphragm filter press; the aerobic tank is connected to the anoxic tank through a sludge return system; the sedimentation tank is connected to the second anaerobic tank through a sludge return device ; The sedimenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com