A Formation Method for Floating Vessels in Tunnel Sections by Immersed Tube Method

A technology of tunnel pipe and immersed pipe method, which is applied in the direction of tugboats, etc., can solve the problems of blank construction methods, etc., and achieve the effect of increasing the window period and good control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

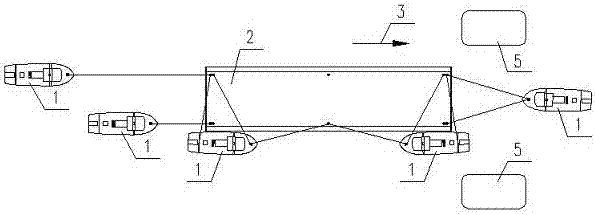

[0017] Example: For an immersed tube section with underwater dimensions of 115m long x 8.3m high x 30m wide, its longitudinal section area A=115x8.3=954.5㎡, cross-sectional area B=8.3x30=249㎡, in water density ρ=1t / m³, water velocity V=0.8m / s, width 70m in the floating channel towing, when the longitudinal section of the immersed tube joint faces the flow (the direction of water flow is perpendicular to the direction of towing), the approximate flow force F= ρV 2 A=611kN; when the cross-section of the immersed tube joint faces the flow (the flow direction is parallel to the dragging direction), the approximate flow force F=ρV 2 B=159kN; the width of the narrowest bridge navigation hole in the channel is 60m; the tugboats are 5 4000HP full-turn tugboats.

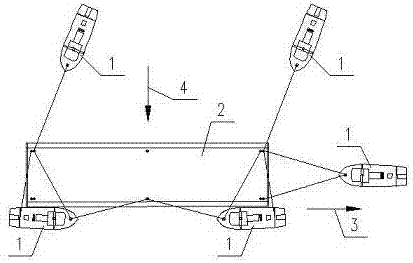

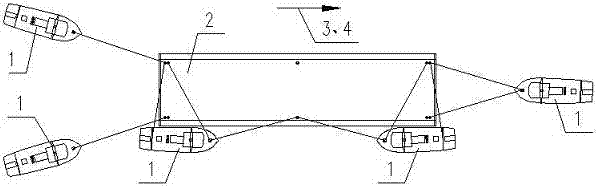

[0018] like figure 1 As shown, when the towing direction 3 of the immersed tube joint 2 is basically perpendicular to the water flow direction 4: one of the tugboats 1 is hoisted at the head of the immersed tube, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com